AdEM™-PTZ

ROMET LTD. 1

1. INTRODUCTION TO AdEM®-PTZ

AdEM®-PTZ is an electronic gas volume conversion device, which provides corrected

volume that is temperature and pressure corrected to standard conditions; applying

compressibility correction factor according to NX-19 or AGA8 or SGERG88 formula

(see Correction Equation for details). Romet combines the power of its field proven

gas measurement technology and integration of computer-based software to come

with the product AdEM®-PTZ. The device can be mounted on Romet rotary meters

or other manufacturers’ pressure bodies. AdEM®-PTZ can be used either as a stand-

alone device or linked to a computer running RometLink software. RometLink is a

powerful tool for device management and advanced data collection/energy

management system.

Characteristic and What's New

✓Compact, light and user friendly

✓Optional portable keyboard eliminates need of integrated pushbuttons, for enhanced security

✓External Scroll button to view parameters of the Custom Display and alarms.

✓Optional to Scroll button the Internal magnetic sensor activated by sweeping magnetic tool to view parameters

of the Custom Display and alarms

✓New firmware with user friendly menus and improved configuration

✓Compatible with new Romet RMT meters

✓B3 compatibility, which can be mounted directly to the meter or with the addition of an AdEM Backup Counter

✓RS-232 or RS485 local and remote communication capability for device management and data collection

✓Audit-trail, Daily Logger, Event Logger/Event Logger Type A, Alarm Logger and Interval data collection features

✓Upgraded Romet RometLink communication software providing a complete data collection system

✓Variety of communication ways

✓3V 8 Digits 14-segment LCD display operable from -40 ˚F to +158 ˚F (-40 ˚C to +70 ˚C)

✓Flash memory makes upgrading firmware easy

✓High and Low pressure, temperature, flow rate and memory error alarms

✓Long life replaceable battery (10 to 20 years in most applications)

✓Battery life indicator for remaining months is based on real battery energy usage calculations

✓Percentage of Battery capacity left

✓External power connection (optional)

✓Pigtail options for Pulse Output connections

✓Selectable output pulse width and spacing to save power

✓Previous Day and Daily Volumes

✓Unc Backup volume reading, the value is same as mechanic Backup Counter

✓AGA8, NX-19 or SGERG88 compressibility calculation method

✓Modbus protocol capable (type RTU) - see Appendix for details

Fig.1 Rotary meter principle

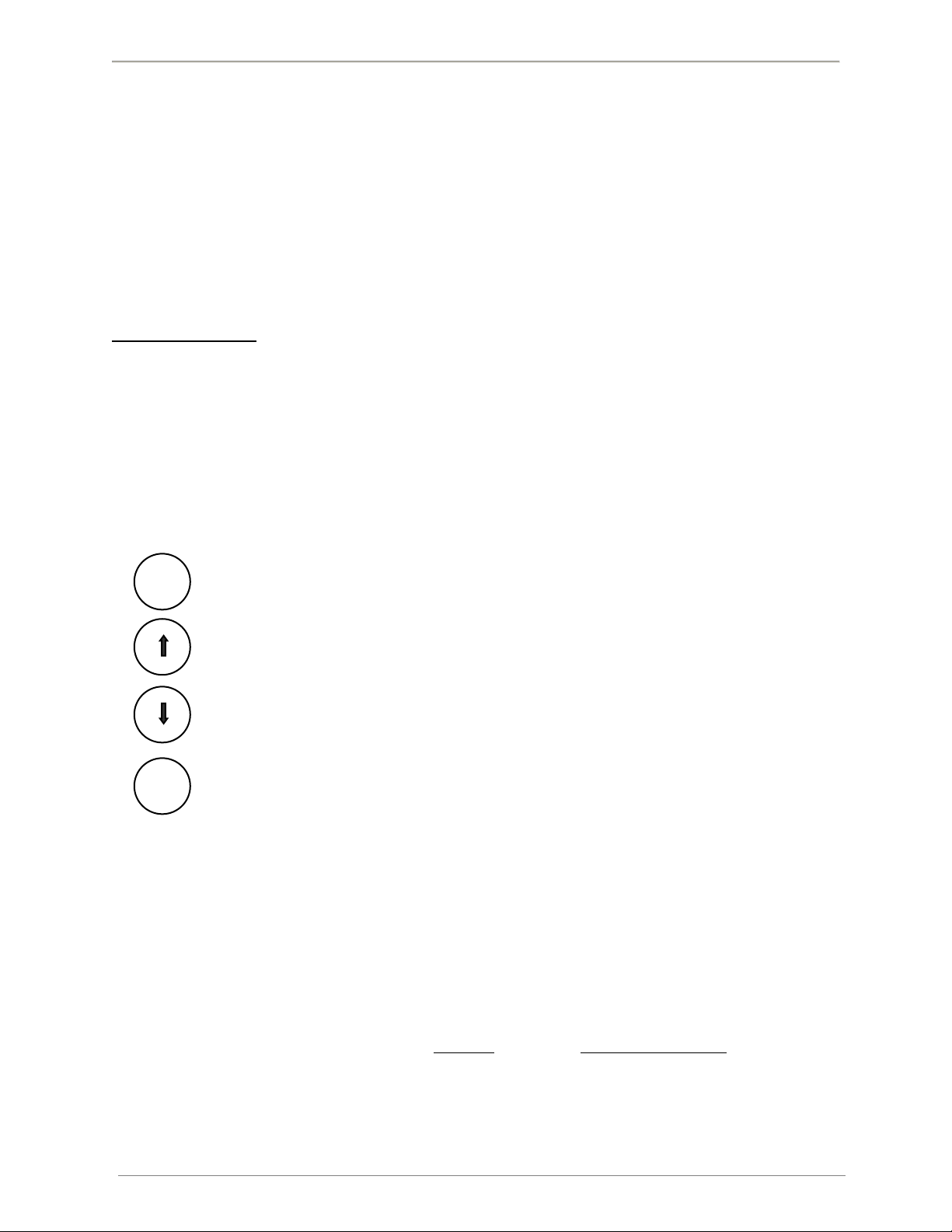

RS232 and Keyboard or

RS485 and Keyborad

Scroll Button (Pushbutton)

Fig.3 AdEM®-PTZ Pigtail Output Pulse connection