9

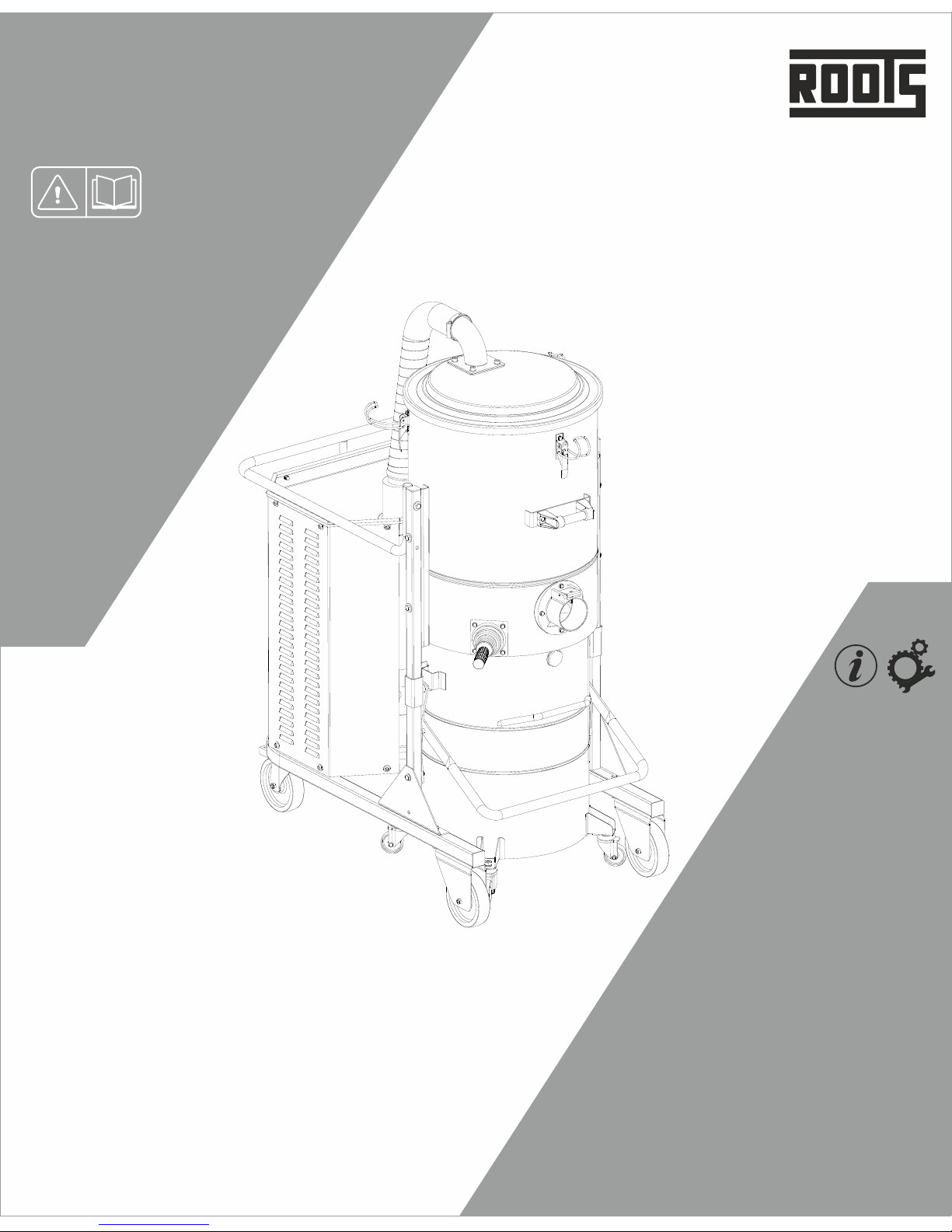

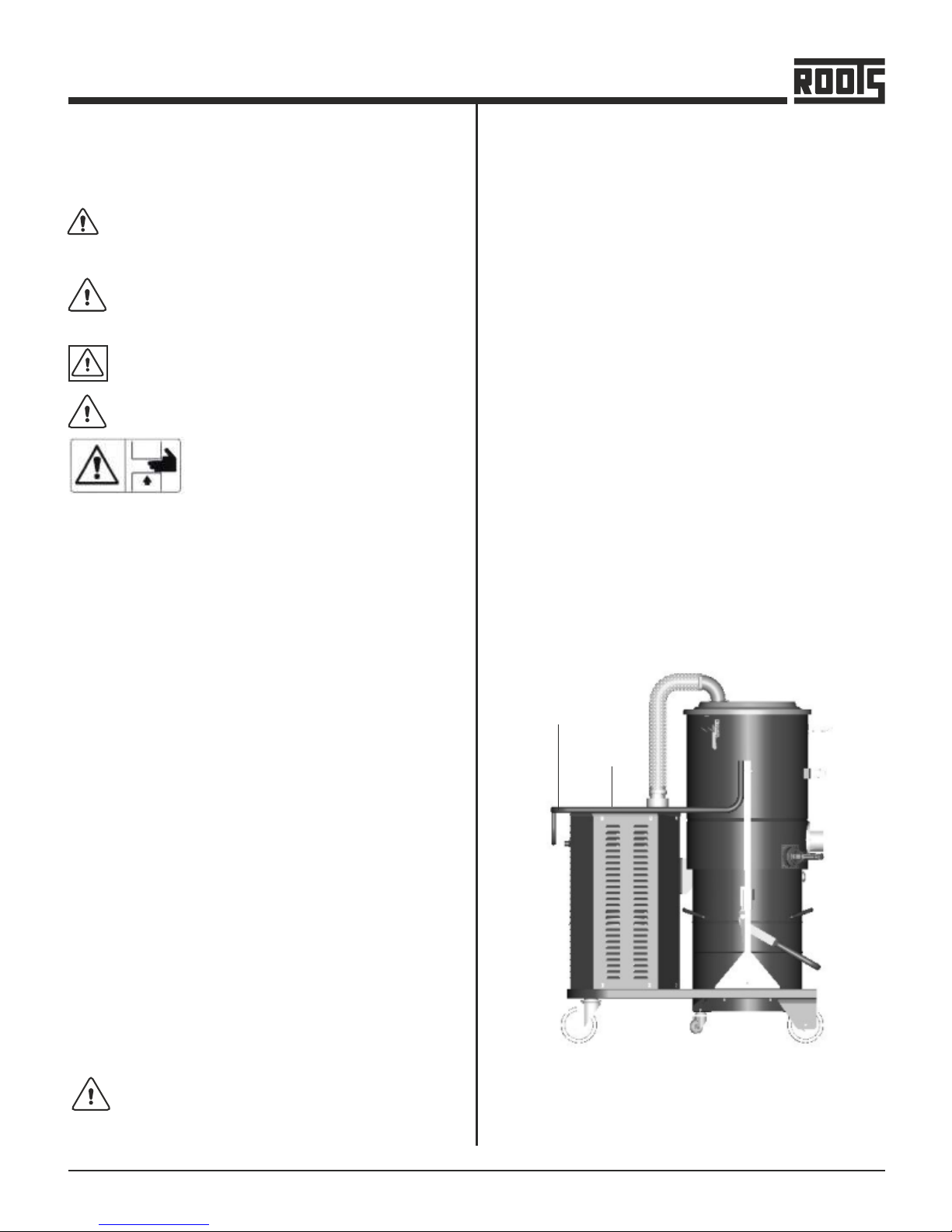

DG - 30 & 70

- Read the operator’s and maintenance manual

carefully before using the cleaner or doing any

maintenance jobs.

- This machine is not intended for use on public roads

and places. Only qualified personnel must perform

maintenance and repair work.

ŸThe machine casing containing moving parts must

not be removed by the user.

ŸUse the machine cautiously on slopes and ramps.

Do not change direction on gradients.

ŸMake sure the parked machine remains stable by

operating the brake wheel.

ŸDuring cleaning operations, maintenance jobs or

when changing parts, the starter switch must be off

and the machine must be disconnected from the

power mains by removing the cable from the socket.

ŸOnly skilled persons should carry out repairs.

ŸPeriodically check the main power cable to ensure

this is not damaged.

ŸIn the event of the cable being damaged, the

machine must not be used.

ŸIn the event of the cable, plugs or couplings being

replaced, make sure these are protected against

water spray and check mechanical strength.

ŸMotor brushes and burnt-out fuses must be replaced

by Roots or authorized dealers. Always use original

spare parts.

ŸThe user is responsible for disposing of vacuumed

substances in accordance with applicable laws.

ŸThe machine must not be operated in a corrosive or

explosive environment.

ŸAlways make sure the machine is free of all foreign

materials such as debris, oil, equipment and other

objects that could affect operation and cause injury

to persons.

ŸAvoid using flammable or toxic solvents such as

petrol, benzene, ether and alcohol for cleaning.

ŸAvoid prolonged contact with solvents and inhaling

their vapors. Avoid close to open flames or sources

of heat.

ŸNever use the machine without the filter.

ŸDo not vacuum lit cigarette ends. The filter could be

damaged.

ŸMake sure all the guards and protection devices are

in place and that all the safety devices are in place

and working properly.

ŸDo not wear loose or hanging clothing such as ties,

scarves or torn garments that could become trapped

and be sucked up by the machine. Do not open the

vacuum container when the machine is running.

ŸThe manual should always be kept handy for

reference so the operating cycle can be checked

every time there are doubts. In the event of this

manual being lost or damaged ask Roots for a new

copy.

ŸStructural damage and improper alterations or

repairs could change the protection capacity of the

vacuum cleaner and therefore cancel this

certification.

ŸDuring maintenance jobs, affix a notice to the

a p p l i a n c e i n d i c a t i n g “ M A C H I N E B E I N G

SERVICED, DO NOT START”.

ŸClimbing on the cleaner is forbidden.

ŸNever touch electric wires, switches, button etc with

wet hands. Before connecting to the power mains,

make sure the power voltage and frequency are

those shown on the machine plate.

ŸMake power connections to a main supply with

efficient earth system. In the event of an extension

being used, make sure this is in perfect condition,

marked CE and that the cross section of the cable is

suitable for the vacuum cleaner power input.

ŸWhen restoring original working conditions, the

appointed personnel should make sure that at the

end of the operating procedure, proper machine

operation safety conditions are restored, especially

the safety devices and the protective guards.

ŸOnly adult persons should use the machine.

ŸDuring vacuuming operations, always brake the

machine using the special revolving wheel lock.

ŸTo ensure the correct operation of the machine, this

must be positioned, protected against atmospheric

agents (rain, hail, snow, fog, dusts in suspension

etc.) With an environmental running temperature

o o

between 5 C to 45 C and relative humidity not above

70%.

GENERAL SAFETY INSTRUCTIONS - Industrial Vacuum Cleaner

Turn the motors off to protect the machine against

unintended movements, before leaving it

unattended.

Never collect explosive fluids, undiluted acids and

s o l v e n t s . T h i s i n c l u d e s e . g . g a s o l i n e

pai nt thinners or f uel o il, whi ch-w hen

combined with air, may form explosive vapors or

mixtures. Acetone, undiluted acids and solvents

can be aggressive to the material used for the

machine components.

- Do not clean the machine by means of

vapour jet or high pressure cleaning

equipment.

- Do not allow water to penetrate the electrical

parts.

- Do not USE the machine on steps.

- This machine splash-water proof.

- Use of the machine in areas prone to explosion

hazards is strictly forbidden.