ROPV R80 S Series Manual August 2005B

General Product Description – R80 S Series

Side Port Membrane Housing

R80 600S Design Pressure: 600 PSI / 4.1Mpa / 41 Bar (at 120°F / 49°C)

R80 800S Design Pressure: 800 PSI / 5.6Mpa / 56 Bar (at 120°F / 49°C)

R80 1000S Design Pressure: 1000PSI / 6.9Mpa / 69 Bar (at 120°F / 49°C)

R80 1200S Design Pressure: 1200PSI / 8.3Mpa / 83 Bar (at 120°F / 49°C)

Min. Operating Temp.: 20°F / -6°C

Max. Operating Temp.: 120°F / 49°C

Factory Test Pressure: ASME: 1.1x Design Pressure

Standard: 1.5x Design Pressure

Burst Pressure: 6X Design Pressure

Operating pH Range: 3 – 11

Cleaning pH Range: 2 – 12 (less than 30 minutes)

General Warning – High Pressure Membrane Housing

ROPV Pressure Vessels are designed to provide safe operation over a long service life

if properly installed, operated, and maintained. The vessel may cause loss of life,

severe bodily harm, or property damage if not correctly installed, operated, or

maintained. Read and understand all guidelines provided in the vessel User Manual.

Observe every precaution contained therein. Failure to do so may result in malfunction

and potential catastrophic failure. It is recommended that only qualified technicians

experienced in servicing hydraulic systems work with this vessel. Misuse, incorrect

assembly, or use of damaged/corroded components may result in catastrophic failure.

Vessel Use and Precautions

•Positive pressure up to the design pressure (PSI) of the specific model being

used.

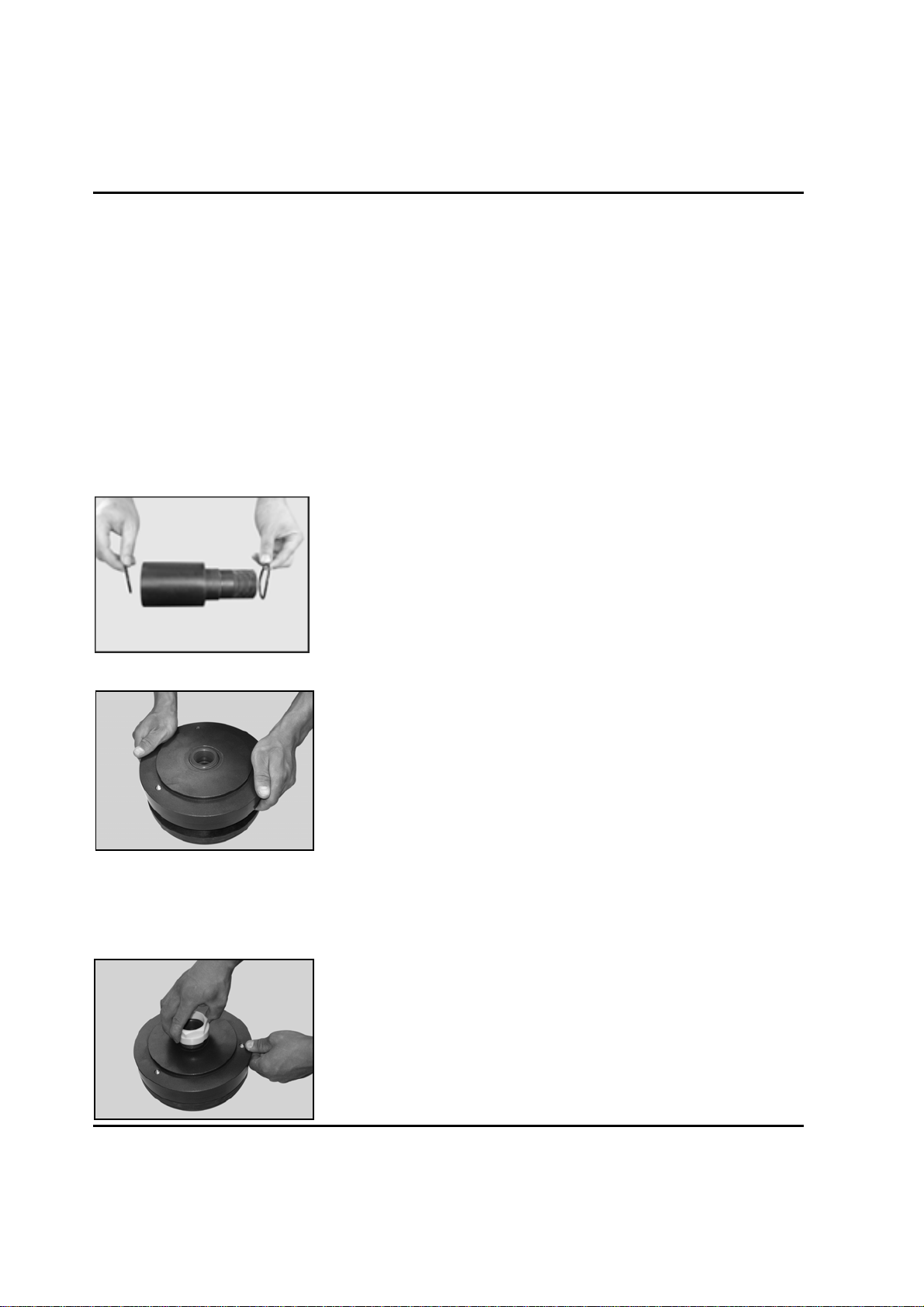

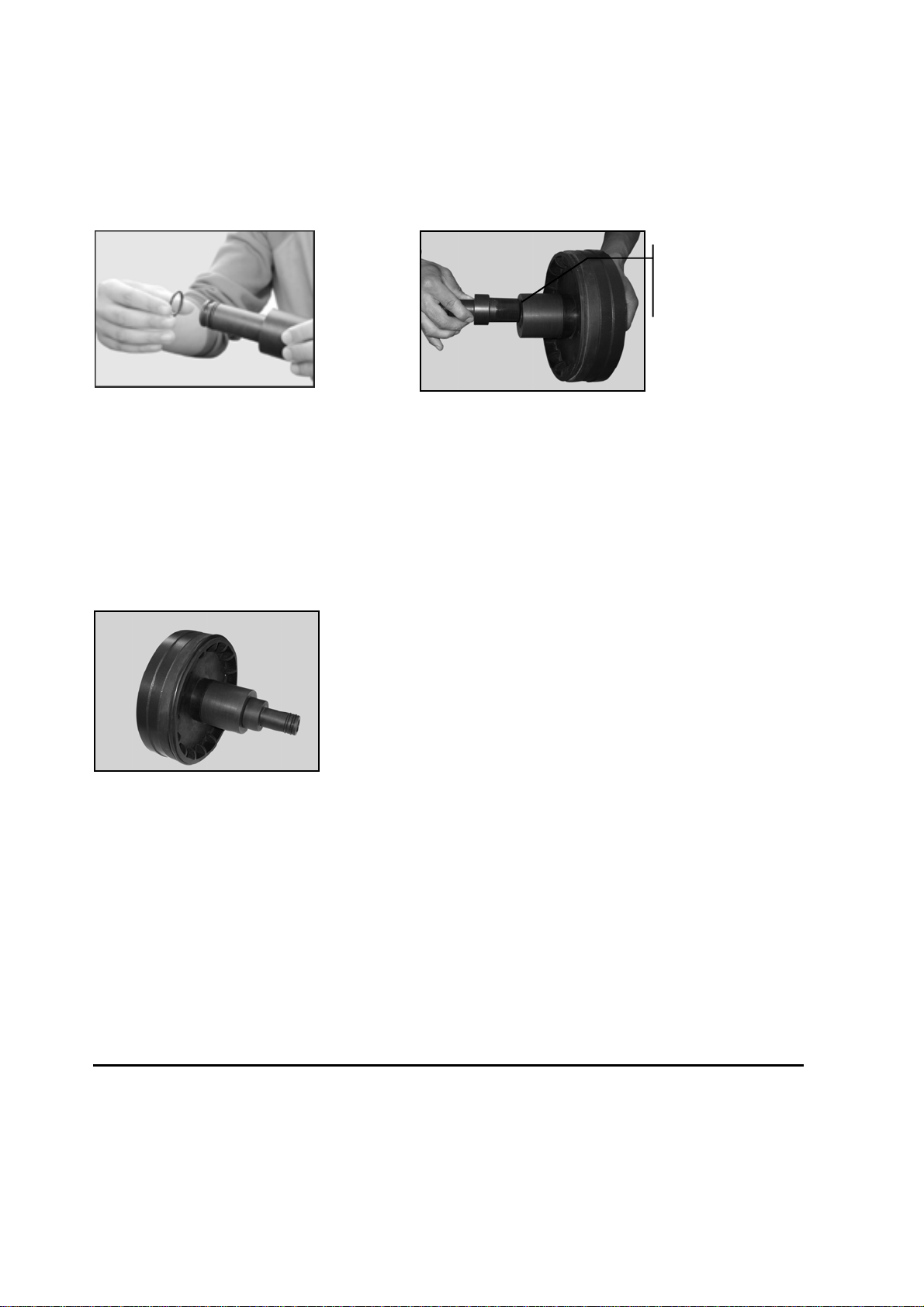

•Accommodates standard 8” nominal diameter spiral-wound element.

•The required vessel/element interface hardware is supplied with the vessel.

Ensure that an element adapter is installed at each end of the vessel before use.

•Vessel expands under pressure and careful consideration must be taken when

installing straps/saddles and system connection piping.

•Installation with the straps/saddles provided is strongly recommended

•Vessel should not support any other system components. Connections should

be non-load bearing.

•Periodic inspection of the vessel end closure is recommended to ensure all parts

are dry and free of corrosion.

•Failure to understand and follow all precautions may void warranty and result in

catastrophic failure of the vessel.