2xSafety

FA ROTEX SC / SCS / HYC - 02/2013 5

2.4 Proper use

The ROTEX Sanicube / HybridCube may only be used as a hot

water storage tank. The ROTEX Sanicube / HybridCube must be

installed, connected and operated only according to the infor-

mation in this manual.

When connecting to a ROTEX heat pump you must use only the

storage tank connection kits (E-PAC) provided for the purpose.

ROTEX Only those electric immersion heaters supplied by

ROTEX may be used.

Any other use outside the intended use is considered as

improper. The operator alone shall bear responsibility for any

resulting damage.

Use as intended also involves compliance with maintenance and

inspection conditions. Spare parts must at least satisfy the

technical requirements defined by the manufacturer. This is the

case, for example, with the use of original replacement parts.

2.5 Instructions for operating safety

2.5.1 Before working on the hot water storage tank

and the heating system

ƔWork on the hot water storage tank and heating system (e.g.

installation, connection and initial start-up) should only be

carried out by authorised and trained heating experts.

ƔSwitch off the main switch before starting any work on the

domestic hot water storage tank and heating system and

secure it against unintentional switch-on.

ƔSeals must not be damaged or removed.

ƔMake sure that the safety valves comply with the require-

ments of EN 12828 when connecting on the heating side, and

with the requirements of EN 12897 when connecting on the

domestic water side.

2.5.2 Electrical installation of optional accessories

ƔBefore beginning work on live parts, disconnect them from the

power supply (switch off main switch, remove fuse) and

secure against unintentional restart.

ƔElectrical installations may only be carried out by qualified

electrical technicians under observance of the relevant

electrical guidelines and the regulations of the electric utilities

company.

ƔFor each hardwired power connection, install a separate

disconnector system compliant with EN 60335-1 for all-pole

disconnection from the power mains.

ƔCompare the mains voltage indicated on the nameplate with

the supply voltage before connecting to the mains.

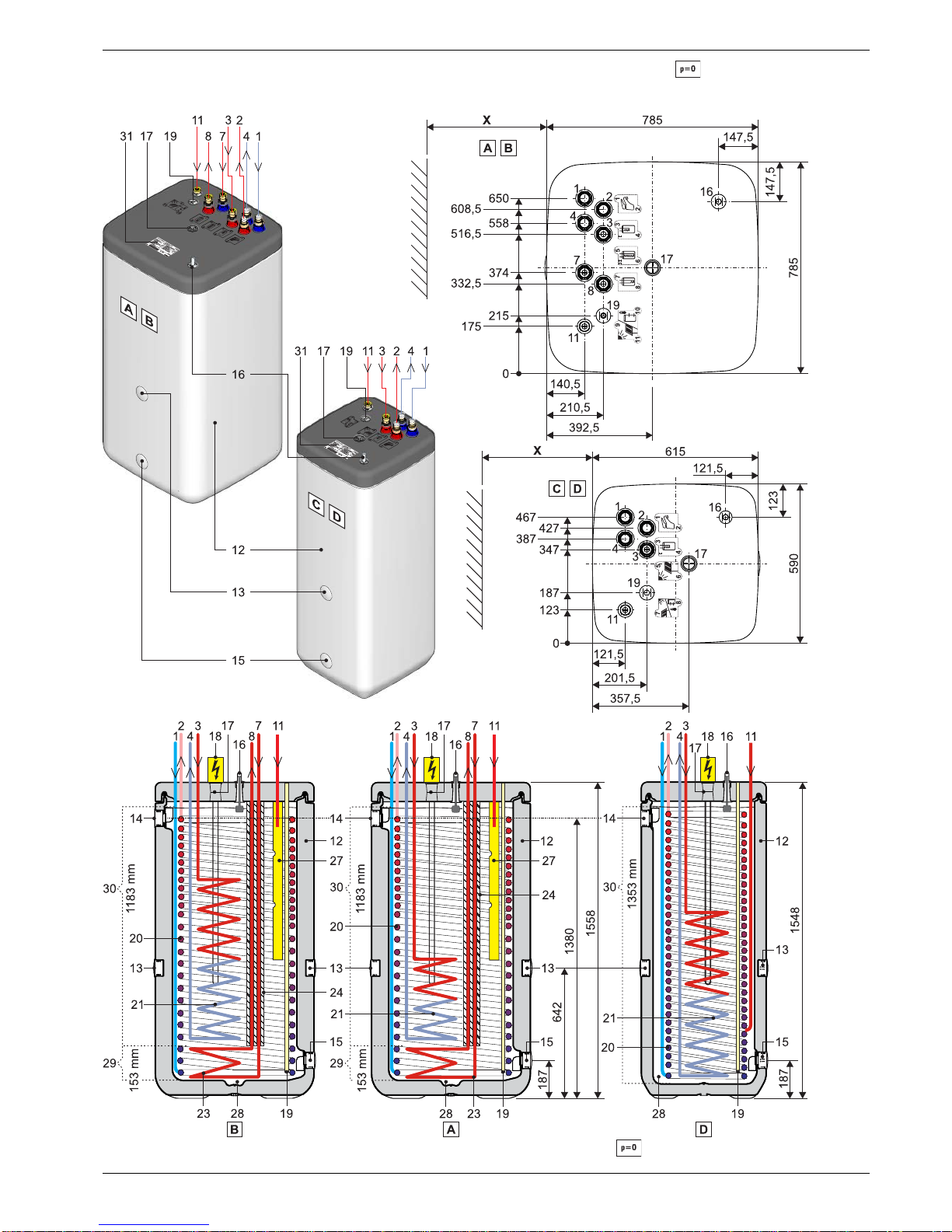

2.5.3 Installation room

For safe and fault-free operation, it is necessary that the instal-

lation location of the ROTEX Sanicube / HybridCube fulfils

certain criteria. Information about the installation location for the

high-performance hot water storage tank can be found in High-

efficiency hot water storage tank chapter 4 "Set-up and instal-

lation".

Information on the installation site of other components can be

found in the associated documentation supplied with them.

2.5.4 Requirements of the heating and filling water

Avoid damages caused by deposits and corrosion: Observe

the current technological regulations to prevent corrosion

products and deposits.

Measures for desalination, softening or hardness stabilization are

necessary, if the filling and top-up water have a high total

hardness (>3 mmol/l - sum of the calcium and magnesium

concentrations, calculated as calcium carbonate).

2.5.5 Heating and sanitary side connection

ƔCreate a heating system according to the safety requirements

of EN 12828.

ƔWith sanitary connection, you must observe;

– EN 1717 - Protection of domestic water from contamina-

tion in domestic water installations and general require-

ments concerning safety equipment for the prevention of

domestic water contamination by back-flow

– EN 806 - Technical regulations for domestic water instal-

lations (TRWI)

– and, in addition, the country-specific legal regulations.

ƔDuring operation of the ROTEX Sanicube / HybridCube in

combination with the solar energy exploitation, the hot water

temperature can exceed 60°C. Scalding protection needs to

be included when you install the system (domestic hot water

mixing device e.g. VTA32, 15 60 16).

ƔUse a pressure reducer if the cold water connection pressure

>6 bar.

2.5.6 Operation

ƔOnly operate the ROTEX Sanicube / HybridCube;

– After all installation and connection work has been com-

pleted.

– With fully installed equipment covers and service

accesses.

– With sanitary side pressure reducers installed

(max. 6 bar).

– With heating side pressure reducers installed

(max. 3 bar).

– With completely filled storage containers (fill level dis-

play).

The specified servicing intervals should be adhered to and

inspection work must be carried out.

2.5.7 Instructing the user/owner

ƔBefore you hand over the heating system and the hot water

storage tank, explain to the owner how he/she can operate

and check the heating system.

ƔHand over the technical documentation (this document and

all supporting documents) to the user and advise him that

these documents must be made available at all times and be

stored in the immediate vicinity of the unit.

ƔDocument the hand-over by filling in and signing the checklist

in chapter 5.1 "Start-up", together with the operator.

2.5.8 Documentation

The technical documentation included in the scope of supply is a

constituent part of the equipment. It must be stored in such a way

that it can be consulted at any time by the operator or the techni-

cians.