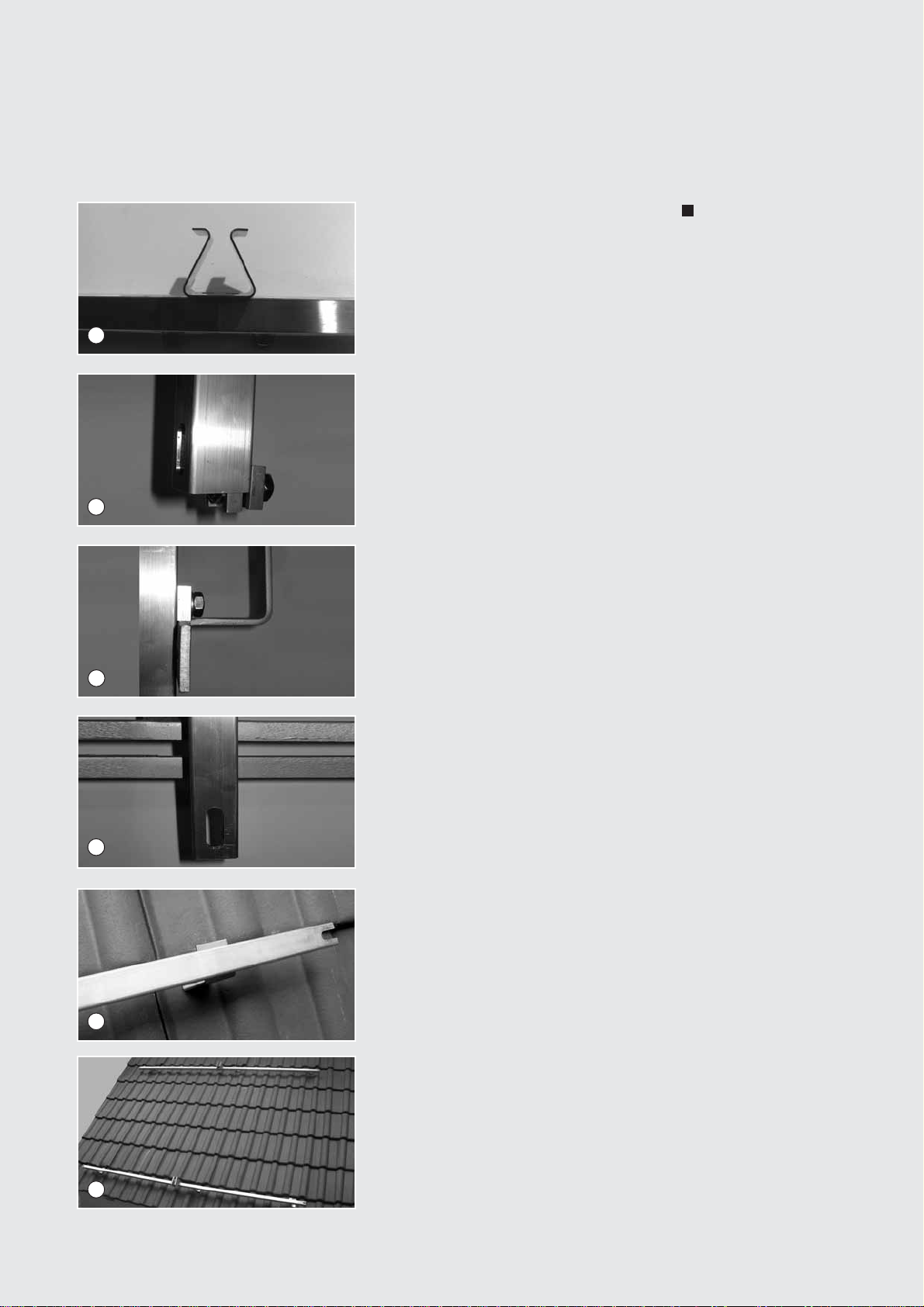

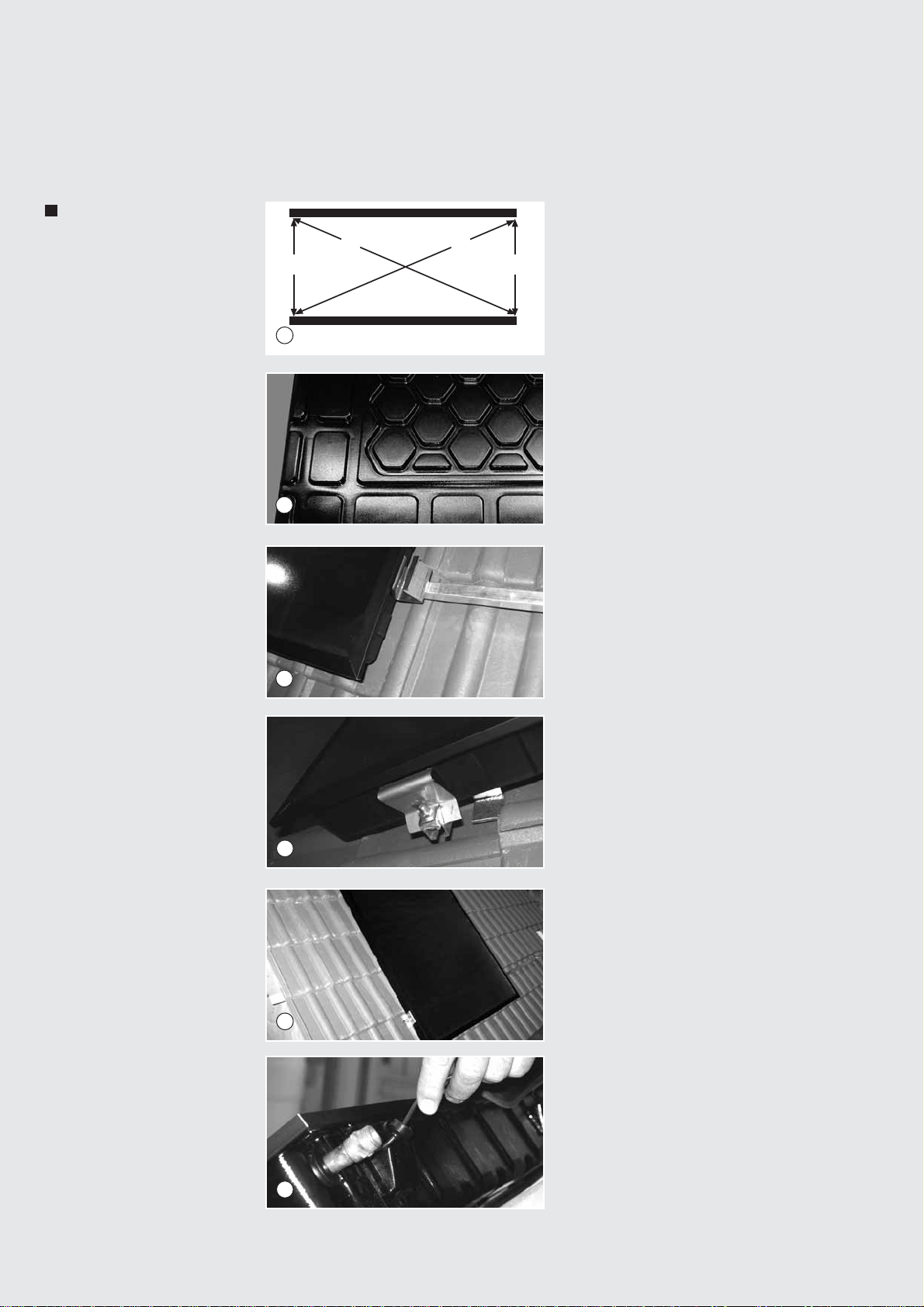

The on-roof attachment set is capable for

installation of Roth flat collectors Heliostar®

on roofs with a slope greater than 22°. One

attachment anchor universal can be used for

roofs with covering made of pantiles/ roofing

tiles and similar roofing stones as well as plain

tiles and fibre-cement corrugated plates.

Installations on roofs made of natural slates

should be carried out by companies employ-

ing professional tilers only.

Please read the installation instructions

before starting the installation carefully

and follow the indicated safety informa-

tion. The valid industrial safety instructions

and regulations of technology especially with

regard to working on the roof have to be

observed (see page 12). In case of higher

loads of snow starting from zone 4 and in

places above 600 m NN, please contact our

technical department to discuss statics of the

installation.

Please note: You may need additional mater-

ial such as ventilation roofing tiles for the roof

lead-through of the collector field connections

(available in special tiler stores and construc-

tion material wholesalers), possibly adjustment

lumbers for padding the rafter anchor, sheet

metal for sealing the rafter anchor when

using plain tiles. To carry the collector on the

roof additional equipment could be required.

Important: When storing the collectors

before installation, make sure the collectors

do not stand outside, lay on the glass and/or

are stocked uncovered, to avoid humidity

entering into the collector through the wholes

in the collector frame. Before installing the

collector connections, they must be annealed.

Therefore, always push strongly against the

1/2” thread connection when tightening.

Non-compliance can result in damage of the

collector.

The metal pipelines of the solar circuit must

be connected through a green/yellow conduc-

tor of min. 16 mm2Cu (H07 V respectively R)

with the main potential adjustment rail. If a

lightning protection installation is available,

the collectors can be linked to it. Earthing can

also be done by a depth earth electrode. The

grounding cable must be placed outside on

the house. In addition the earth electrode

must be connected with the main potential

adjustment rail with a cable of the same

diameter.

Installation requirements

Safety information

Generel requirements

Potential adjustment

and lightning

protection

2

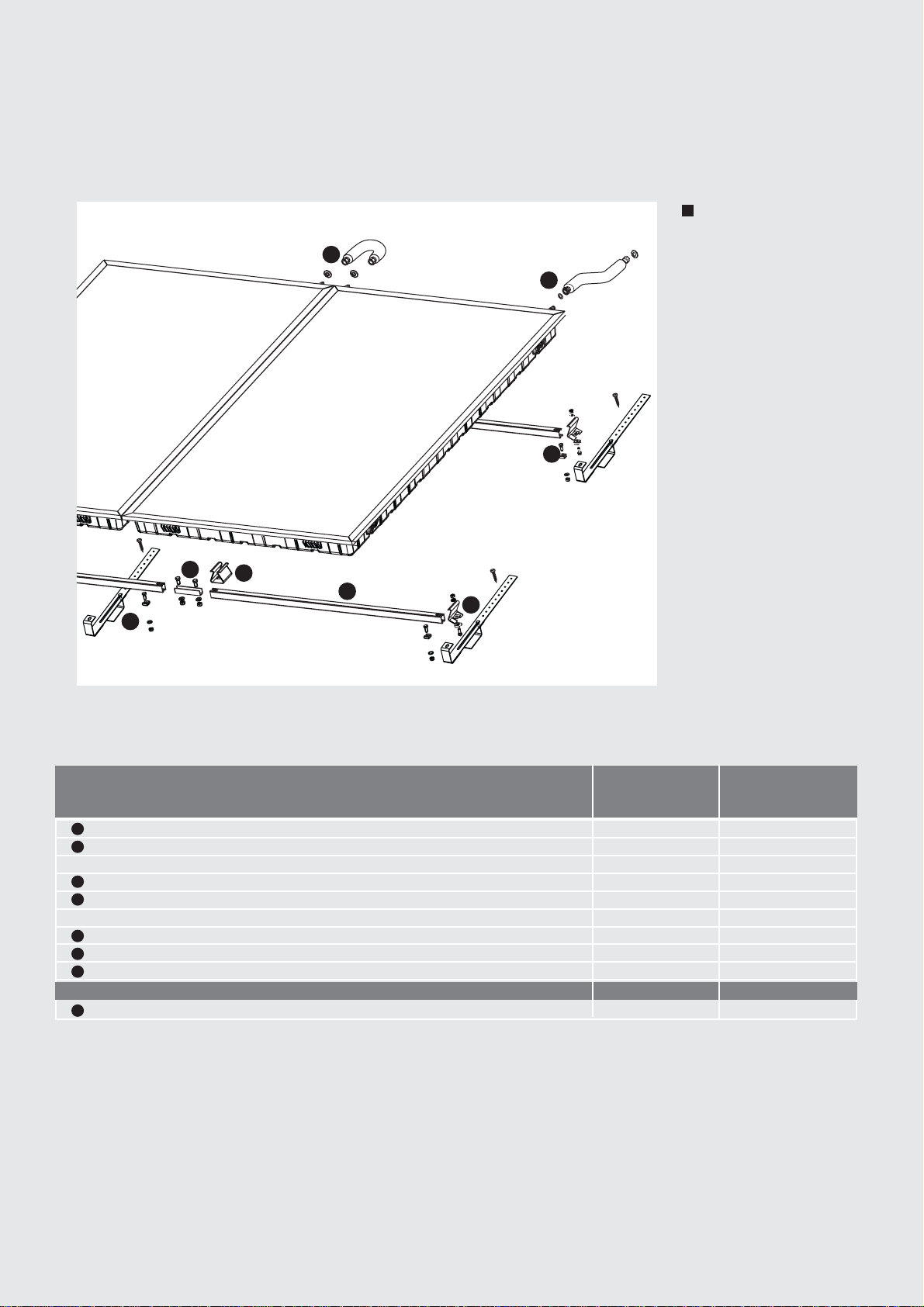

• Spanner 13/17/19/20/22

• Boring machine,

• Cross slot PZ 3

• Angle grinder with stone shim

• Hammer

• String (approx. 10 m), measuring tape, rope

• Pencil

Overview of tools

The sensor must be installed in the last flood-

ed collector on the supply side (hot outlet).

For this purpose, the rubber sleeve must be

removed, the sensor must be threaded and

the rock wool inside of the collector should be

pushed aside. Afterwards place some heat

conducting paste on top of the sensor and

insert it as far as possible into the immersion

sleeve. In the end push the rubber sleeve back

into its position until the countering lip inter-

locks with the collector frame. To extend the

cable of the sensor up to 50 m it is sufficient

to choose a cable diameter of 2 x 0,75 mm,

for more than 50 m a diameter of 2 x 1,5 mm

must be used. To protect the connected regu-

lation units against overvoltage the collector

sensor is to be extended appropriately, directly

behind the collector, through an overvoltage

protection case (optional).

Installation of sensor