2

Safety instructions

2

Please read these assembly instructions

carefully prior to installation and ensure

adherence to all safety instructions.

Always ensure adherence to all relevant Work

Safety regulations and that all technology is

state-of-the-art, in particular where relevant to

roof work

Important: With this type of assembly, it

may not be possible to completely empty the

collectors. For this reason, the solar system

should only be lled with a mixture of water

and antifreeze. This means that it is also

essential to top up the collectors with antifreeze

after pressure or functional tests!

Important: If collectors are stored prior to

assembly, always ensure that they are never

stored in the open air, lying on their glass sur-

face and/or uncovered, as this may allow mois-

ture to penetrate the vent holes in the frame.

When installing the collector connectors, please

bear in mind that they are soft-annealed, so

counter-pressure should always be applied

when tightening the ½” threaded joint! Failure

to do so may result in damage to the collector!

Safety instructions

Work Safety regulations

and state-of-the-art tech-

nology

• Roof installations: DIN 18338

Roof covering and roof sealing works,

DIN 18339 Sheet-metal works, DIN 18451

Scaffolding works.

• Connecting thermal solar systems:

DIN 4757 Parts 1 and 3.

• Electrical connection: VDE 0100 Setting up

electrical equipment, VDE 0185 general

information for erecting lightning protection

systems, VDE 0190 main equipotential

bonding of electrical systems, DIN 18382

electrical cable and wiring system in

buildings.

The professional builders associations provide

detailed information on accident prevention

regulations!

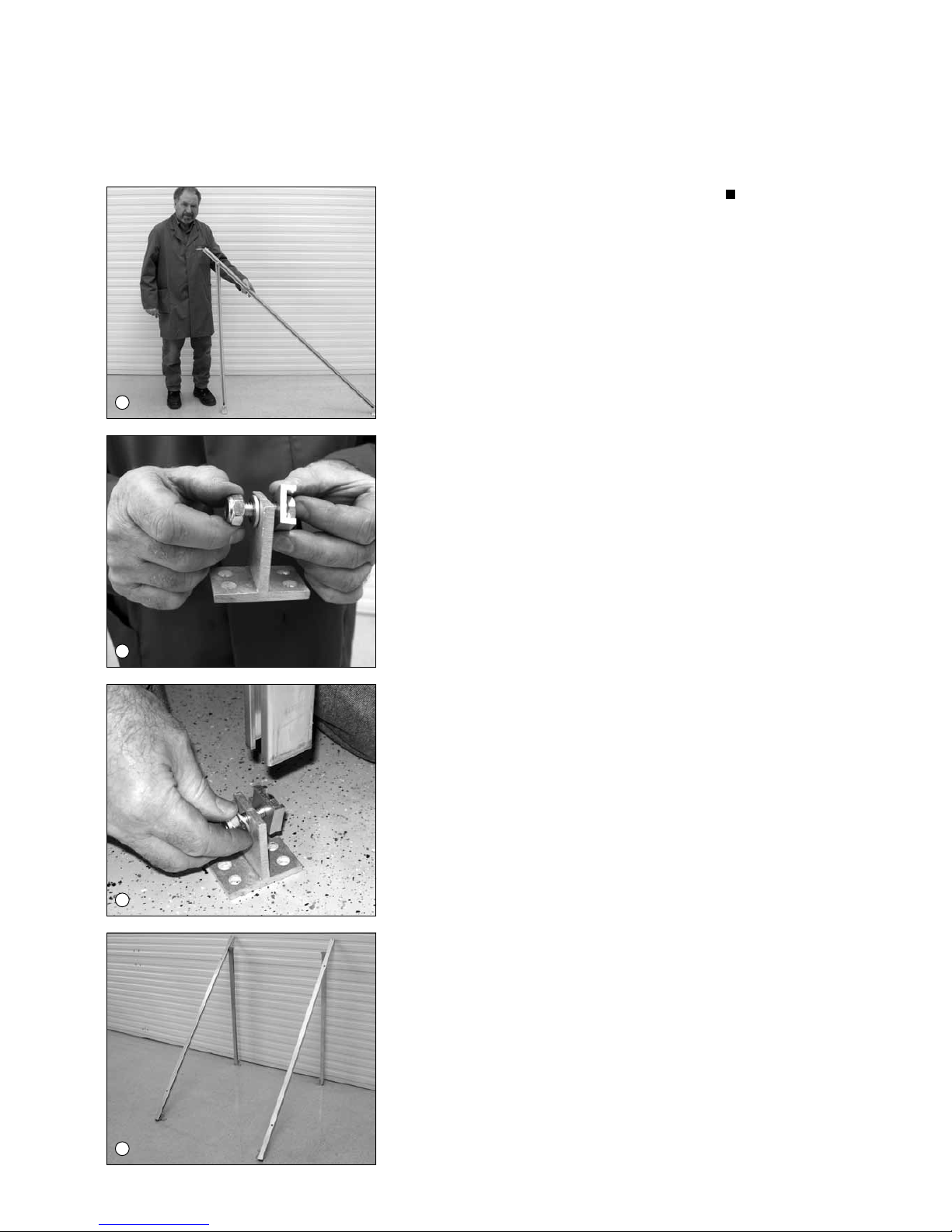

Proper use of ladders

Ladders should only be used for a working

height below 5 m. Position the ladder at an

angle of 65° to 75° and secure. The top end

of the ladder must extend at least 1 m above

exit point.

Fall protection

If working at a height above 3 m, always

use fall protection equipment when working

on sloping roofs (20° to 60°) (VBG 37, § 8).

The vertical distance for a workplace safety

device (roof safety platform or other kind of

protective roof barrier) is max. 5 m. A safety

harness may also be used as fall protection.

Secure universal fastening safety anchors to

load-bearing parts above the worker. Do not

use ladder hooks!

Protection against falling objects

Access routes and workplaces located below

the work site must be protected against falling

objects. These areas must be clearly signed and

cordoned off.

Information is also available on the

Roth Hotline: 0 64 66/9 22-2 66