Before installation, please read the safety instructions at the end of this

installation manual very carefully – and make sure you are using the latest

edition of these instructions.

Layout and planning of this installation system should be conducted using the

ALUMERO Solar.Pro.Tool software. Please ensure you have all the requisite

materials, positioning and layouts for each individual component according

to the project report provided with Solar.Pro.Tool, and/or by your ALUMERO

sales partner. The data have all been calculated within statutory static toleran-

ce levels and are of great importance to the safe and smooth operation of the

system.

Prior to commencement, technicians responsible for installing the photovoltaic

system must ensure the existing roof construction is capable of bearing the

additional loads and forces. We suggest contacting a local statics specialist.

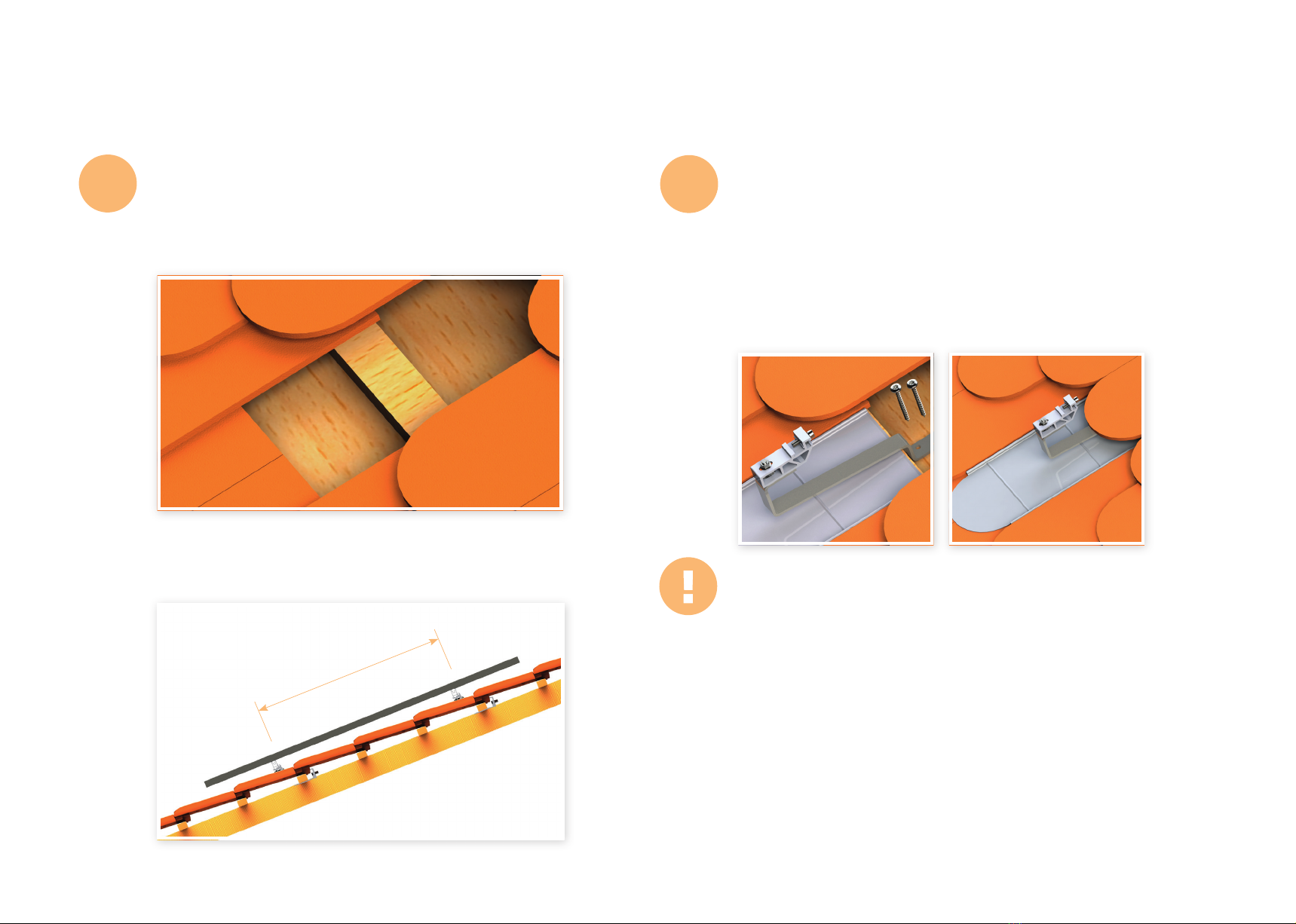

This installation instruction manual explains installation procedures for ALU-

MERO tiled roof components, attachment to the substructure for the roof, and

assembly of the modules.

Modules are usually mounted vertically to tiled roofs with the truss profiles pa-

rallel to the roof ridge. Two truss profiles per module row are used as standard.

The ALUMERO tiled roof system is intended solely to carry PV modules. Any

other applications of the system shall be considered examples of misuse.

The use of extra-tilt fixtures is not recommended for tiled roofs.

Mounting must only be conducted by trained personnel. Roofing tasks in parti-

cular should only be carried out by professional roof contractors.

If you have any other questions, please take advantage of our comprehensi-

ve professional advisory service provided by ALUMERO’s expert construction

engineers.

LIST OF CONTENTS

General information................................................................................................. P 3

Components........................................................................................................... P 4-5

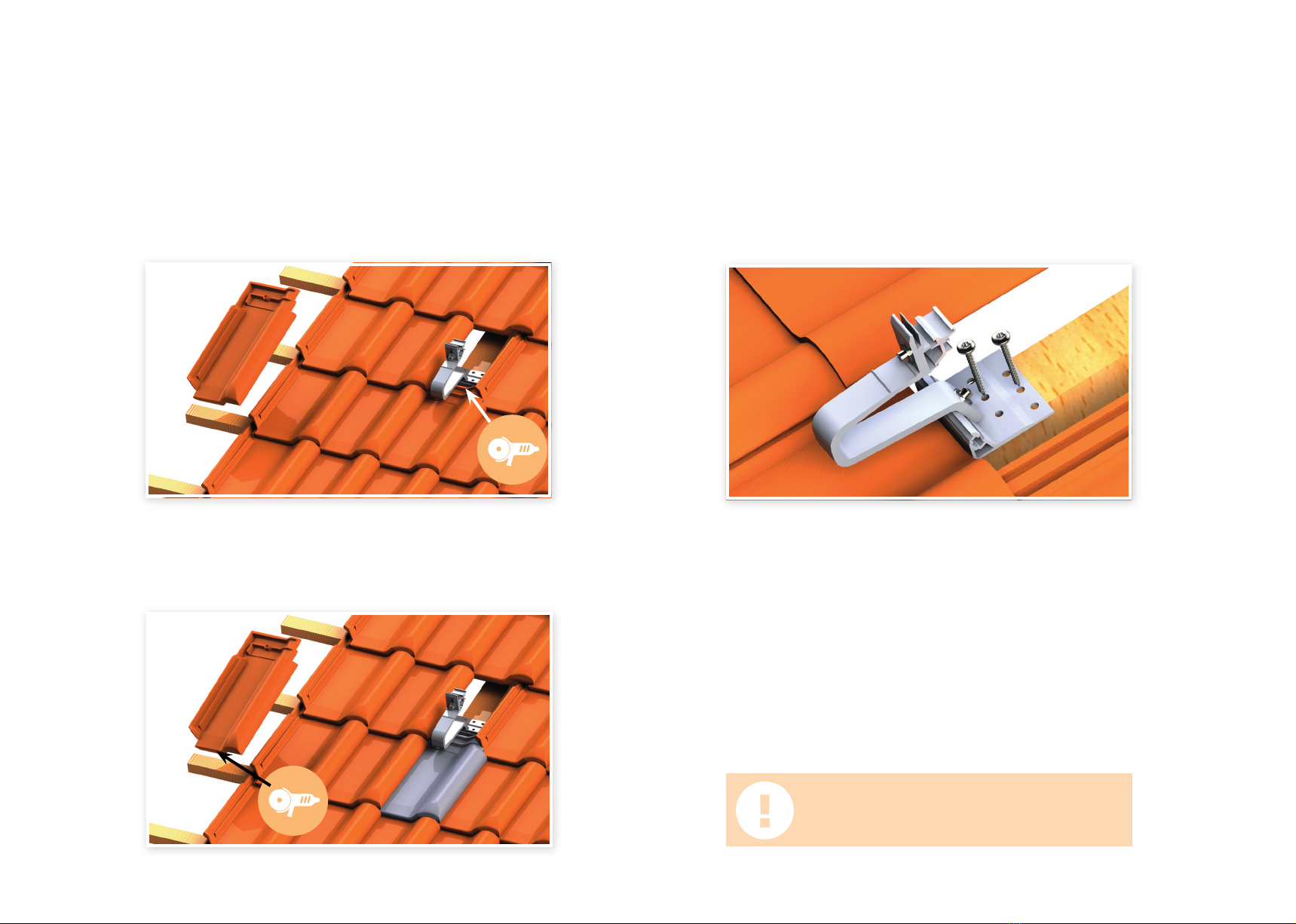

How to attach roof hooks.................................................................................... P 6-9

How to attach beaver tail tile roof hooks........................................................... P 10

How to attach slate tile roof hooks...................................................................... P 11

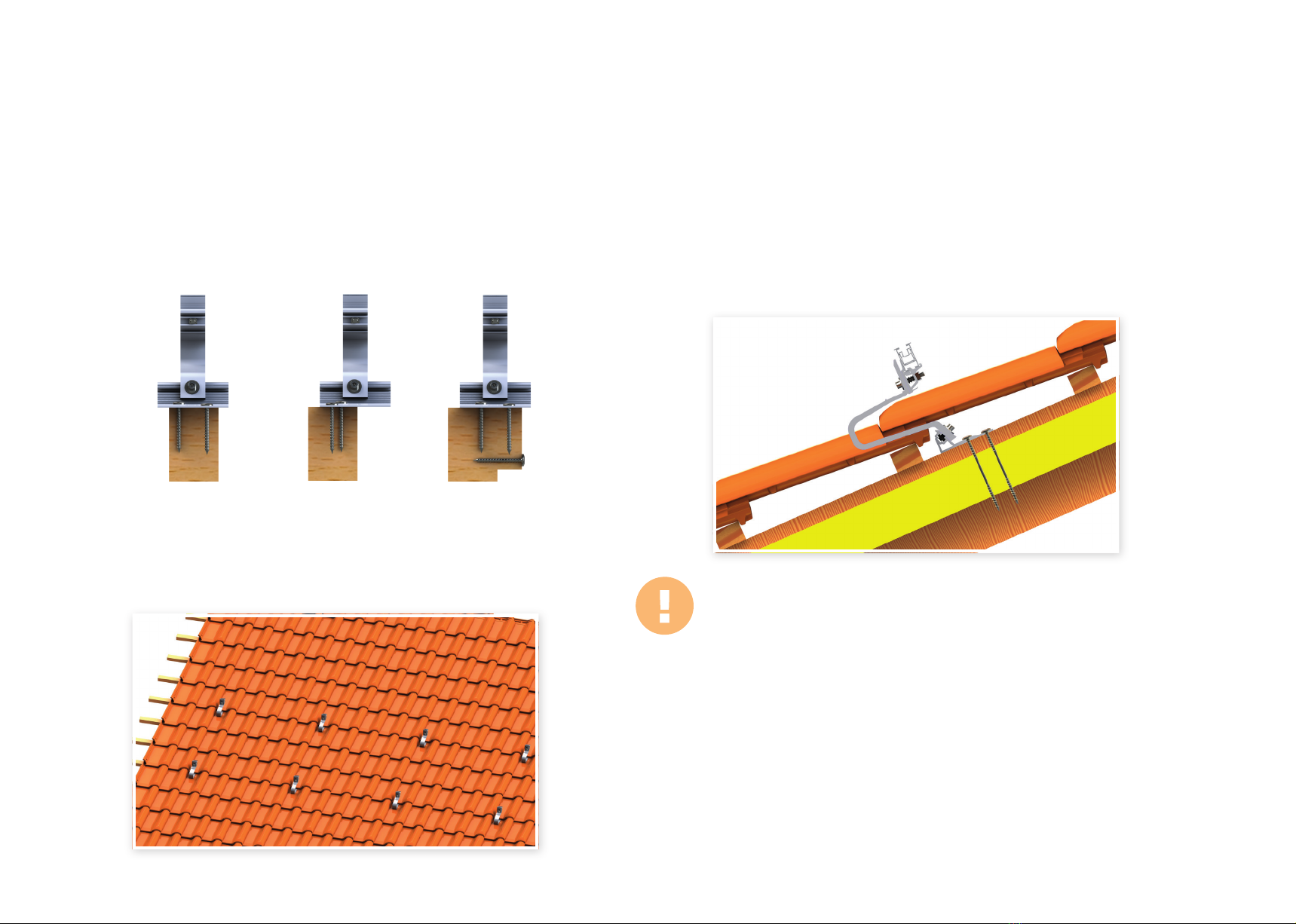

How to mount truss profiles in a single direction...................................... P 12-13

How to mount truss profiles in a lattice arrangement............................... P 14-16

How to mount modules.......................................................................................... P 17

How to attach AL13 X roof hooks.................................................................. P 18-20

How to mount modules.......................................................................................... P 21

How to attach module cables | Equipotential bonding | Earthing........... P 22-23

Key points........................................................................................................... P 24-28

2