3

1INTRODUCTION.....................................................................................................................4

1.1 SAFETY INSTRUCTIONS................................................................................................4

1.1.1

LOSSES NOT COVERED BY WARRANTY

.....................................................................4

1.1.2 TIGHTENING BOLTS AND ENSURING THEIR TIGHTNESS...................................4

2WARNINGS AND OBSERVATIONS.......................................................................................5

3TECHNICAL DETAILS THAT MUST BE ACCOUNTED FOR WHEN STARTING TO USE

THE DEVICE...........................................................................................................................6

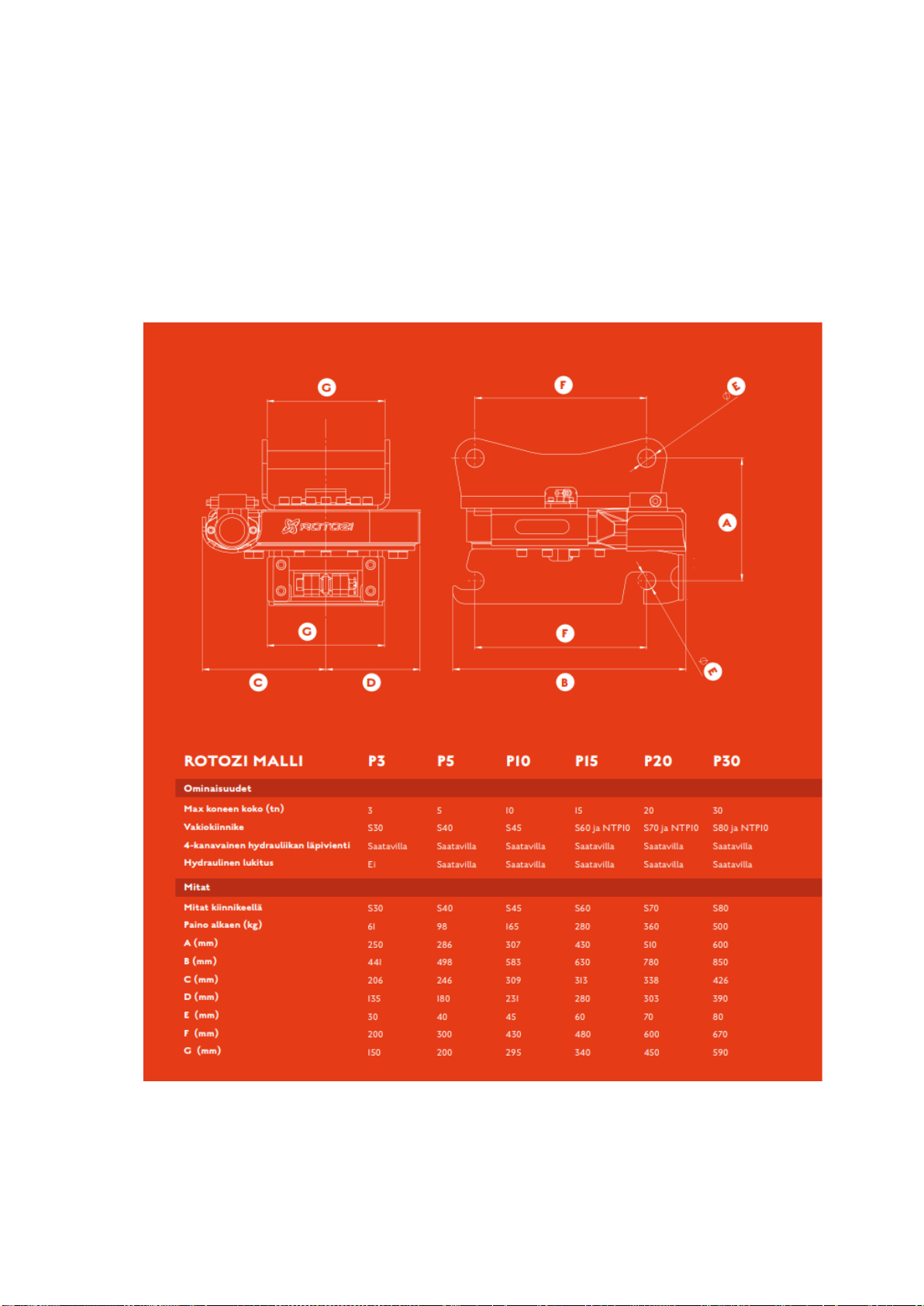

3.1

DIMENSIONS

.....................................................................................................................6

3.2

BUCKET ROTATOR INSTALLATION (check the following)

.......................................................7

3.3

MOUNTING THE CONNECTOR ON THE ROTOZI ROTATOR.

................................................8

3.4

ATTACHING A TOOL TO THE ROTATOR (buckets, forklift spikes, etc.)

.....................................9

3.4.1 Manual locking...........................................................................................................9

3.4.2 Hydraulic locking........................................................................................................9

3.5

REMOVING THE TOOL FROM THE ROTATOR

...................................................................10

3.5.1 Manual locking.........................................................................................................10

3.5.2 Hydraulic locking......................................................................................................10

3.6

REMOVING THE BUCKET ROTATOR CONNECTOR

...........................................................11

3.7

INSTALLATION OF HYDRAULICS ON THE ROTATOR

.........................................................12

3.8 INSTALLING THE HYDRAULIC LOCKING ....................................................................13

3.9 CENTRAL LUBRICATION..............................................................................................15

3.10 LUBRICATION INSTRUCTIONS:...................................................................................15

4USING THE ROTATOR WITH THE MACHINE.....................................................................16

4.1 MAINTENANCE..............................................................................................................16

4.2 WARNINGS AROUND THE AREA WHERE THE MACHINE IS USED...........................17

5WARRANTY..........................................................................................................................18