Schaeff HT 12 User manual

HT 12 Unimog 1.96 1

1 Introduction

1.1 General

You decided to buy a Schaeff backhoe excavator HT 12.

The confidence placed in this model will be rewarded by the efficient and economical

performance of the machine.

These operating instructions contain all information necessary for the correct use of the

machine. Please read them carefully before putting the machine into operation and

make sure that they are kept at hand at all times.

Should you need further explanations or should anything be unclear, please contact

your dealer immediately.

Special equipment and attachments are not included in these operating instructions.

We reserve the right to make improvements on the machine within the scope of

impending technical developments, without incurring any obligation to change these

operating instructions.

Note

Any modifications of Schaeff products and their equipment using extras and work

attachments which are not included in our product range require our written

approval. If our approval is not sought, our warranty expires, as does our product

liability for any resulting consequential damages.

Note

The vehicle identity number of the

backhoe excavator is stamped on the

identification plate located on the slide.

Please state the machine type and the

machine identity number when making

inquiries or orders, and in all written

correspondence.

Our address :

Head Office / Sales Service Spare Parts

Karl Schaeff GmbH & Co. Karl Schaeff GmbH & Co. Schaeff Ersatzteile-Service

Maschinenfabrik Maschinenfabrik GmbH & Co.KG

Postfach 61 • D-74595 Langenburg Postfach 1264 • D-91534 Rothenburg Postfach 12 64 • D-91534 Rothenburg

Schaeffstr.8 • D-74595 Langenburg Erlbacher Str. 113 • D-91541 Rothenburg Erlbacher Straße 113 • 91541 Rothenburg

Tel. +49 7905 58-0 Tel. +49 9861 972-451 Tel. +49 9861 972-0

Fax +49 7905 58-114 Fax +49 9861 972-460 Fax +49 9861 972-410

2HT 12 Unimog 1.96

1.2 Proper use

The backhoe excavator with standard

bucket, grab or loading bucket

equipment is intended solely for work

which is suitable for the function of the

machine and its work implements.

Such work involves loosening, taking up,

transporting and dumping rock or other

materials as well as loading these

materials on conveyor belts or other

means of transport.

Any usage above and beyond that

specified here and any non-compliance

with the manufacturer’s instructions is

regarded as improper use. The

manufacturer shall not be liable for

damages resulting from improper use.

This risk is borne solely by the plant

operator.

Compliance with the operating and

maintenance instructions, the

performance of maintenance work as

specified and adherence to replacement

intervals all form part of the concept of

proper use.

1.3 Warranty and Maintenance

Safe working conditions and good

working order of the machine are

prerequisites for efficient work. Your

Schaeff backhoe excavator fulfils these

requirements when correctly handled

and when serviced and maintained as

specified.

Careful observation of the machine

whilst in function and the use of the

specified lubricants will prevent

malfunction.

Trained specialist personnel are

responsible for any servicing of the

machine which requires expert

knowledge. Inspections and repairs

must therefore be carried out by your

dealer’s customer service.

In respect of possible claims for

damages during the warranty period,

all customer service work specified in

the maintenance and inspection plan

must be carried out at the specified

intervals.

After the warranty period, too, regular

maintenance must be performed in

order to ensure that the machine is

constantly in good working order and

enjoys a reasonable service life.

Insist that only original SCHAEFF

spare parts are used in the event of

any repair work. In this way, you will

have a product of lasting high quality,

thereby ensuring that your machine

maintains its original condition.

HT 12 Unimog 1.96 3

1.4 Delivery and handing-over

instructions

The following checklist is to be

adhered to when handing over the

machine.

Operating instructions

The operating instructions should be

read side by side, and be explained in

detail through practical training on the

machine.

•Regulations for preventing accidents

published by the employer’s liability

insurance associations in the user’s

country

•Technical data

•Operational elements, control and

warning indicators

•Checks before putting the machine

into operation

•Actuation of all functions

•Explanation of maintenance and

inspection intervals according to

Maintenance and Inspection Plan by

demonstrating maintenance points on

machine

•Lubrication intervals and points of

lubrication according to lubrication

chart and demonstration of these

points on the machine

Spare parts list

•Structure of spare parts list, figures

and the respective descriptions

•Instructions for ordering spare parts:

always state the type of machine, the

vehicle identity number (Fz-Id.Nr.),

parts designation, complete spare

part number, piece number, delivery

address, etc.

Warranty

•Explanation of warranty covered by

manufacturer

•Explanation of inspection cards and

note on maintenance and inspection

plan

•Correct filling out of

warranty/handing-over card and

returning the latter to Schaeff

1.5 Notes on using the instruction

book

References to pictures and items

The references to pictures and

items contained in the text, such as

“Figure 2/4“ or (2/4) mean figure 2,

item 4 (Bild = Figure).

The figures shown in this list partly

contain additional equipment.

Attention

This danger symbol is used when

inexact compliance or non-

compliance with operating

instructions, specified work

procedures, etc. may lead to injury

or fatal accidents.

Note

This symbol is employed when

inexact compliance or non-

compliance with operating

instructions, specified work

procedures, etc. may lead to

damage to the machine. This

symbol is also used for information

which is of particular importance to

the user of the machine.

4HT 12 Unimog 1.96

2 Accident prevention

2.1 Before putting the earth-moving

machine into operation, read these

operating instructions carefully and

strictly observe the indicated references.

Note

Some of the following points are

based on the laws and regulations

valid for the Federal Republic of

Germany. This is the case for the

regulations for the prevention of

accidents mentioned in paragraph

2.2, which only apply to Germany.

For all other countries, local

regulations apply.

2.2 National safety regulations, e.g. the

Accident Prevention Regulations (UVV)

published by the employer’s liability

insurance associations in the user’s

country must be strictly observed. One

copy of the Accident Prevention

Regulations applicable for excavators,

loaders, etc. (Earth-moving machines

VBG 40), published by the “Tiefbau-

Berufsgenossenschaft“, is supplied with

the machine or can be obtained from

this organisation. We recommend

reading these regulations carefully. The

site operator and the driver of the

machine are responsible for compliance

with safety regulations.

2.3 If necessary, but at least once a

year, earth-moving machines must be

submitted to a general inspection

according to the existing UVV

regulations (Accident Prevention

Regulations). This inspection has to be

carried out by an expert (e.g. machine

engineer or machine foreman). The

results of this inspection must be

recorded in writing and this record must

be kept until the next inspection takes

place.

2.4 The operation of earth-moving

machines may only be assigned to

suitable and reliable persons of the

minimum legal age, and the site

operator or his deputy must make sure

in advance that these persons are

familiar with the operation of the

machine.

2.5 In case defects cannot be remedied

immediately, the driver of earth-moving

machines has to report any

shortcomings immediately to the

supervisor and his replacement, if there

is a change of operator. Defects which

may lead to dangers must be remedied

immediately.

2.6 Daily before commencing work and

after every change of work attachments,

the correct fastening of the work

attachments must be verified. Work

attachments are to be carefully moved

at low height.

2.7 Prior to and during work, the drivers

of earth-moving machines must ensure

that nobody who may be jeopardised is

in proximity of the machine. If

necessary, warning signals are to be

given.

2.8 Whenever they are stopped, earth-

moving machines must be reliably

secured to avoid any unintentional

movement.

2.9 It is the driver’s responsibility to

ensure that the operator’s stand and

other parts of the machine which have

to be stepped on are free of dirt, grease,

oil, ice and snow.

HT 12 Unimog 1.96 5

2.10 Only carry out maintenance and

repair work on the excavator when the

work equipment is lowered to the

ground, the engine is switched off, and

the hydraulic system is relieved of

pressure.

With the engine off, lower the work

equipment to the ground and actuate all

hydraulic control levers until there is no

pressure in the hydraulic system.

Attention

When working under the raised

work equipment, it is essential to

secure the latter by appropriate

means.

2.11 Never attempt to lift the

machine yourself or leave it in

that position for repairs.

Place pieces of wood between

the jack and the machine when

jacking up the machine. Be aware

that shifts in weight may occur.

6HT 12 Unimog 1.96

3 Technical data

3.1 Working diagram

Fig. 4

HT 12 Unimog 1.96 7

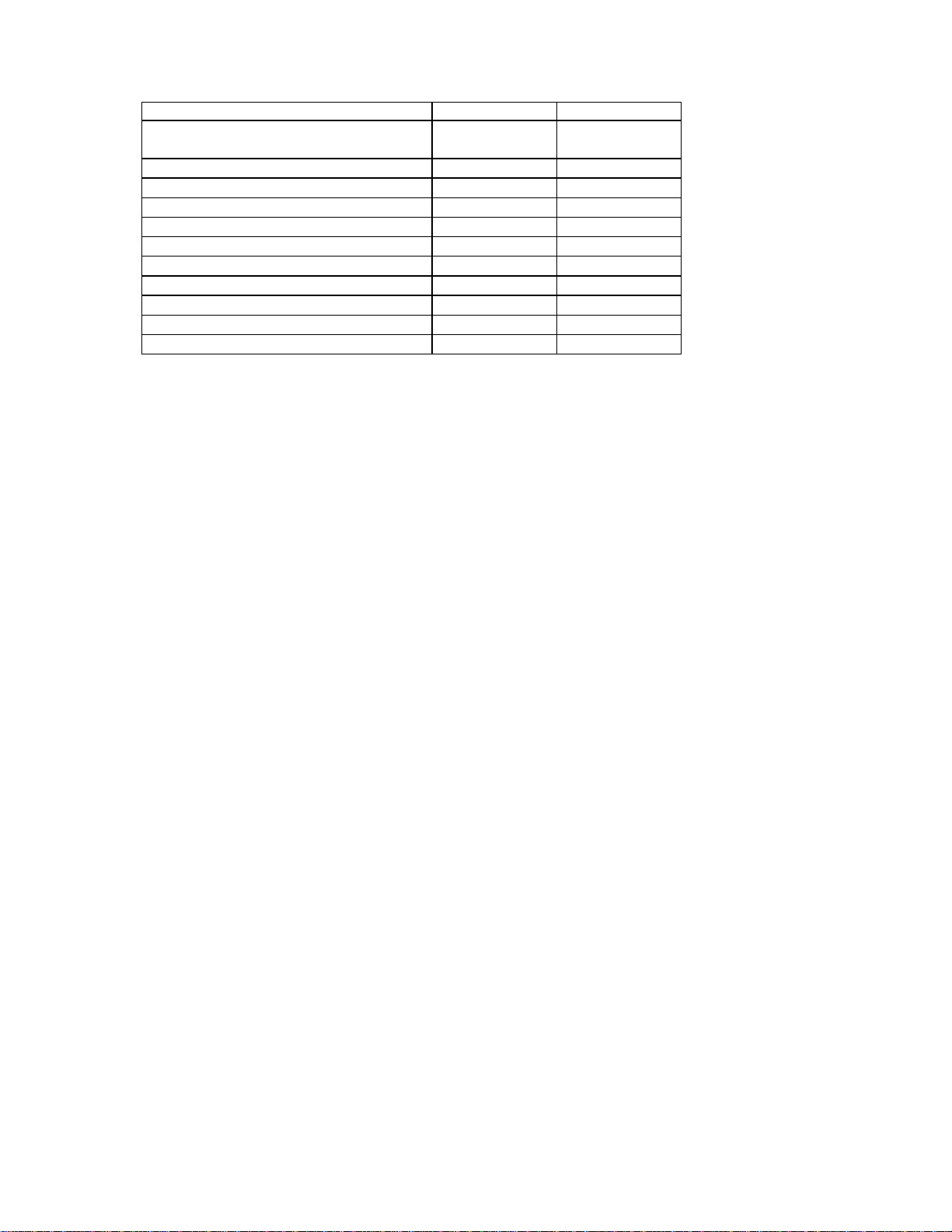

3.2 Dimensions and weights without mounting group

Dipperstick 1,500 mm 1,800 mm

Operating weight in kg

without work attachments approx. 1250 approx. 1300

Digging depth in mm 3,600 3,900

Dumping height in mm 3,200 3,200

Max. reach in mm“ 5,050 5,350

Bucket turning angle in ° 195 195

Boom slewing area in ° 185 185

Lateral parallel adjustment in mm 1,260 1,260

Total width in mm 2,000 2,000

Payload at max. reach in N 8,600 7,500

* Ripping force in N 25,000 22,000

* Breakout force in N 28,550 28,550

* Values are theoretical according to DIN 24086

Dimensions apply for standard bucket 280 - 800 mm.

3.3 Hydraulic system - Technical data

Power required for

hydraulic system 20 - 28 kW

Working pressure 175 bar

Capacity 70 - 80 l/min

Tank filling quantity approx. 54 l

Hydraulic oil temperature max. 90°C ( ΔT 60°C )

8HT 12 Unimog 1.96

3.4 Lubricant specifications

Hydraulic system: Mineral hydraulic oils

The limit values for hydraulic oils which can be used

for Schaeff construction machines and attachments

are approx. 12 mm ²/s (cSt) at 100°C and approx.

1500mm ²/s (cSt) at -10°C. See also hydraulic oil

recommendation chart for Schaeff construction

machines and attachments.

Biodegradable hydraulic oils

As an alternative to mineral oils, we recommend bio-

degradable hydraulic oils of a synthetic ester base.

The same viscosity specifications apply as for

mineral oils.

Note

When changing from mineral to biodegradable

hydraulic oils, the tank and hydraulic system must be

completely drained, cleaned and flushed.

For further details before changing oils, please

consult your Schaeff dealer.

Grease nipples: Multi-purpose grease to DIN 51825-K 2 G-40

Note

The safety data sheets of the mineral oil companies must be observed when dealing with

lubricants.

3.5 Work attachments

Width Capacity

Bucket with ejector 290 mm 0.062 m

3

Bucket with ejector 350 mm 0.072 m

3

Bucket with ejector 450 mm 0.100 m

3

Bucket 600 mm 0.164 m

3

Bucket 800 mm 0.204 m

3

Ditch-cleaning bucket 1,250 mm 0.115 m

3

Ditch-cleaning bucket 1,500 mm 0.160 m

3

Clamshell grab 350-450 mm

- Further work attachments available on request -

HT 12 Unimog 1.96 9

3.6 Other equipment

•Load hook in connection with overload warning device

•Ripper tooth

•Overhead guard

•Cab

•Widened support

- Further optional equipment available on request -

Note

Any modifications of Schaeff products and their equipment using extras and

work attachments which are not included in our product range require our

written approval. If our approval is not sought, our warranty expires, as does

our product liability for any resulting consequential damages.

10 HT 12 Unimog 1.96

4 Mounting and dismounting instructions

4.1 Mounting

Note

The host vehicle must be equipped with the appropriate mounting group.

• The host vehicle must be driven backwards to the backhoe excavator.

• Establish hydraulic connection for excavator by connecting the hydraulic hoses to the quick

couplings.

• Connect the connection hoses of the tilt cylinder with the Unimog-connecting boxes.

• Switch on power take-off.

• Adjust the excavator with stabilisers and dipperstick to level.

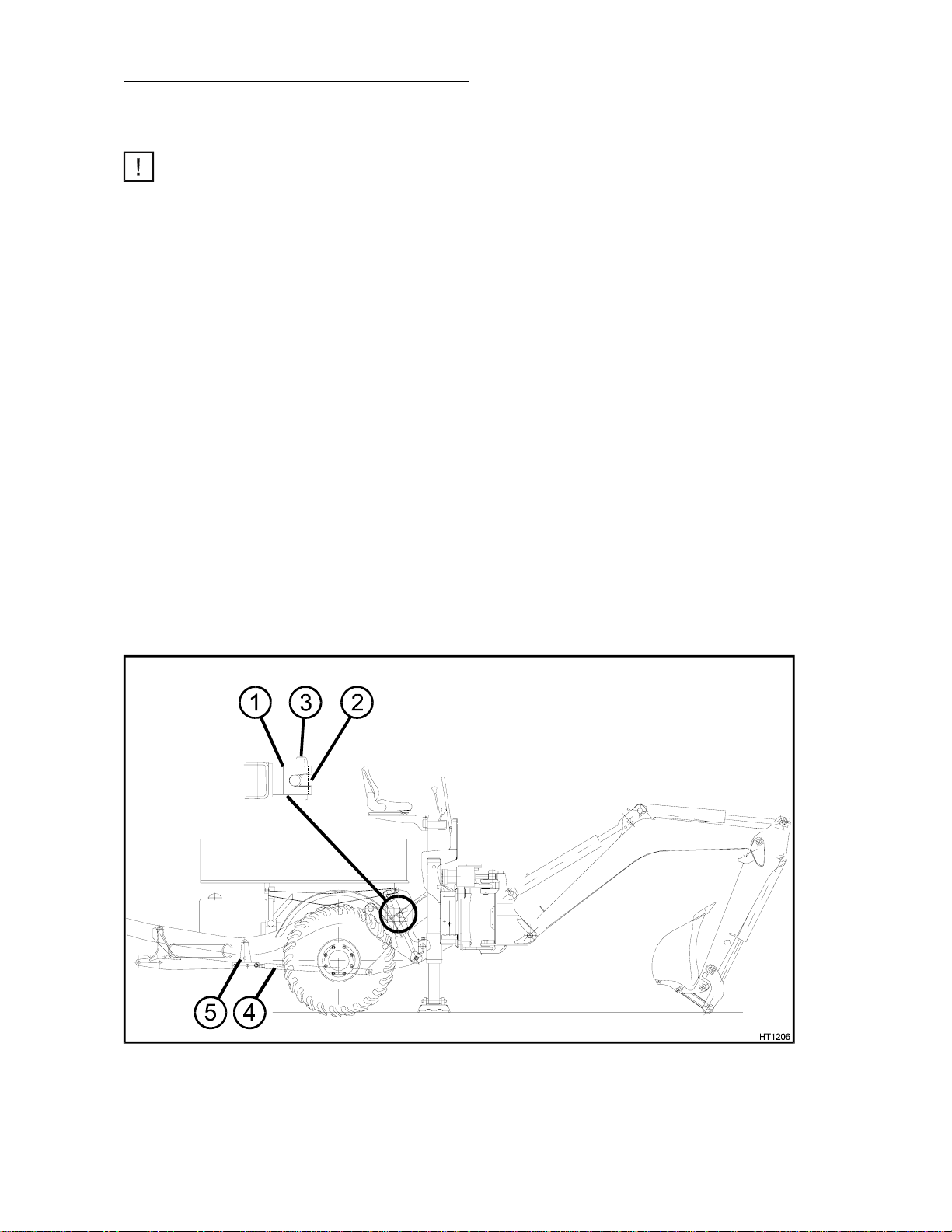

• Drive host vehicle backwards and hook the backhoe excavator in slide (6/1).

• Fasten and secure the excavator using retaining blocks (6/2) and pins (6/3).

• Attach the arm (6/4) in the middle of the vehicle on the „center of the underslung frame“ (6/5).

• Bring the excavator to working position and check functions.

• The backhoe excavator is now ready for operation.

4.2 Dismounting

• Move the slide to the middle of the mounting plate.

• Place the working equipment to the ground.

• Lift the backhoe excavator by actuating the stabilisers to such a degree that the Unimog is no

longer burdened by the excavator.

• Loosen the excavator fastening (retaining blocks and arm ).

• Move the host vehicle forward so that the backhoe excavator stands free.

• Retract the stabilisers, turn off the power take-off and stop the engine.

• Loosen the hydraulic connection for the excavator and the tilt cylinders. Connect the air hose

to the return line hose on the host vehicle.

• Protect the connection hoses of the backhoe excavator from contaminations.

fig. 6

HT 12 Unimog 1.96 11

5 Operation

5.1 Operator controls

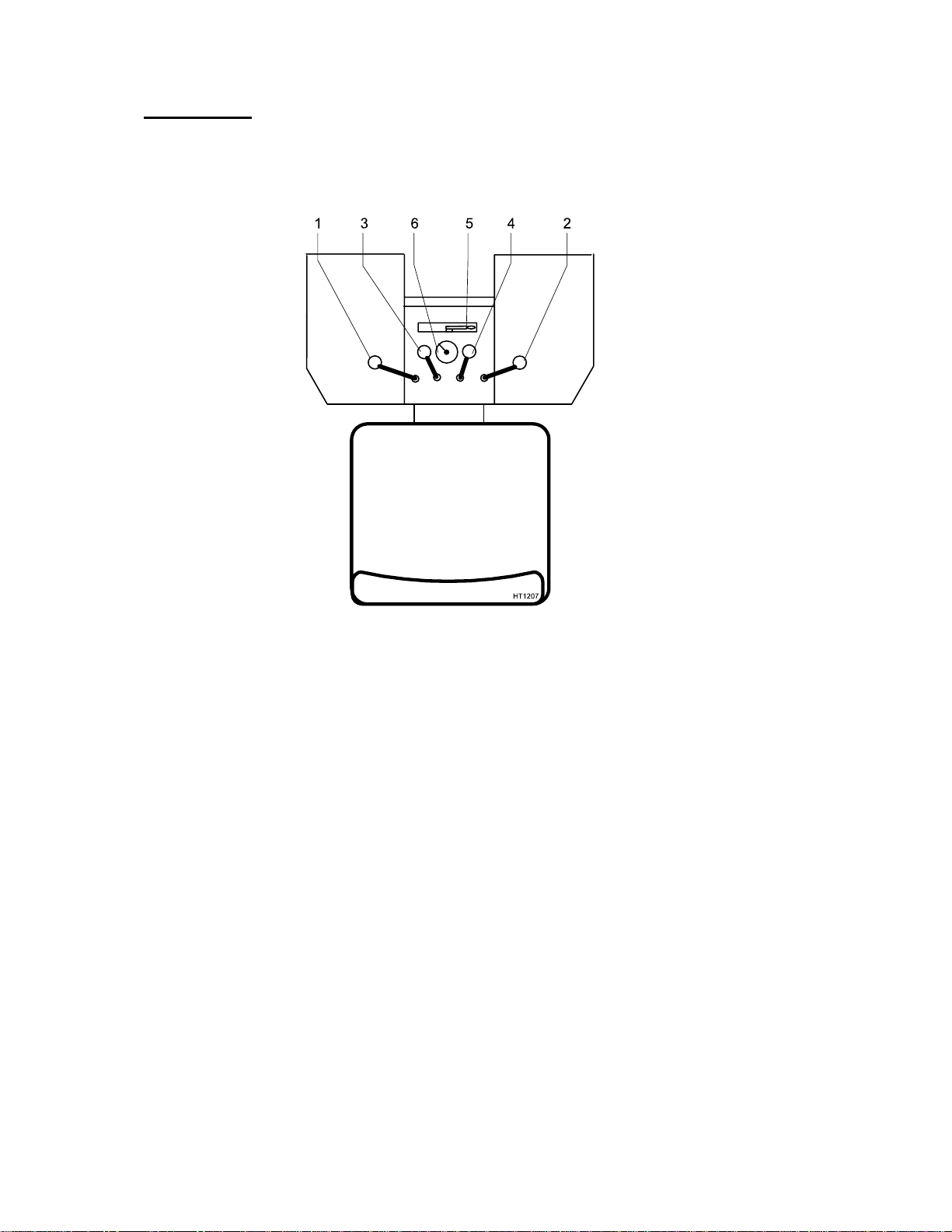

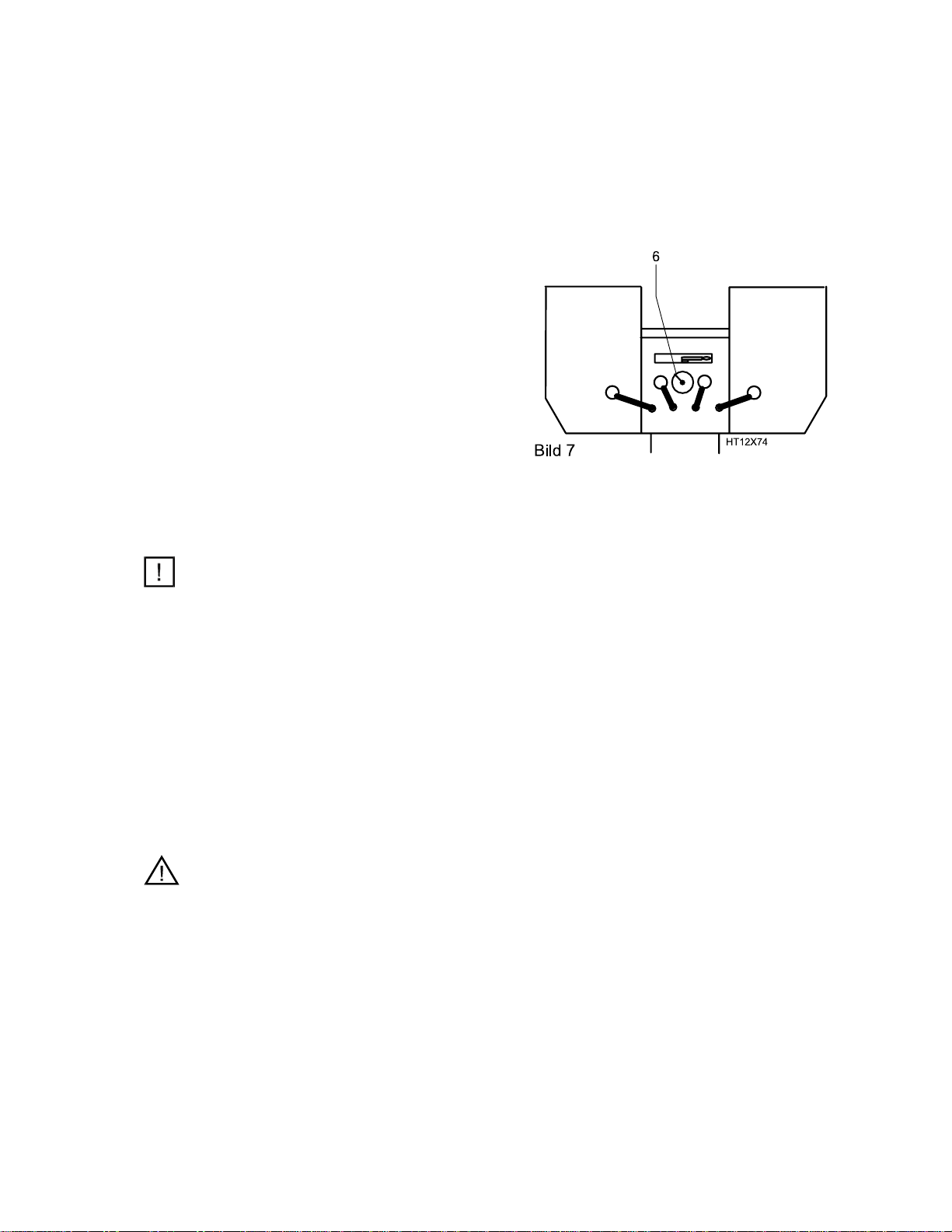

Fig. 7

1 Operator control for excavator equipment

2 Operator control for excavator equipment

3 Operator control for stabiliser, right

4 Operator control for stabiliser, left

5 Slide lock

6 Overload warning device

12 HT 12 Unimog 1.96

5.2 Making the backhoe excavator ready for

operation

•Start the Unimog according to the Unimog -

operating instructions and let the engine run at

idle speed.

•Lower the excavator from transport to working

position according to chapter 6.

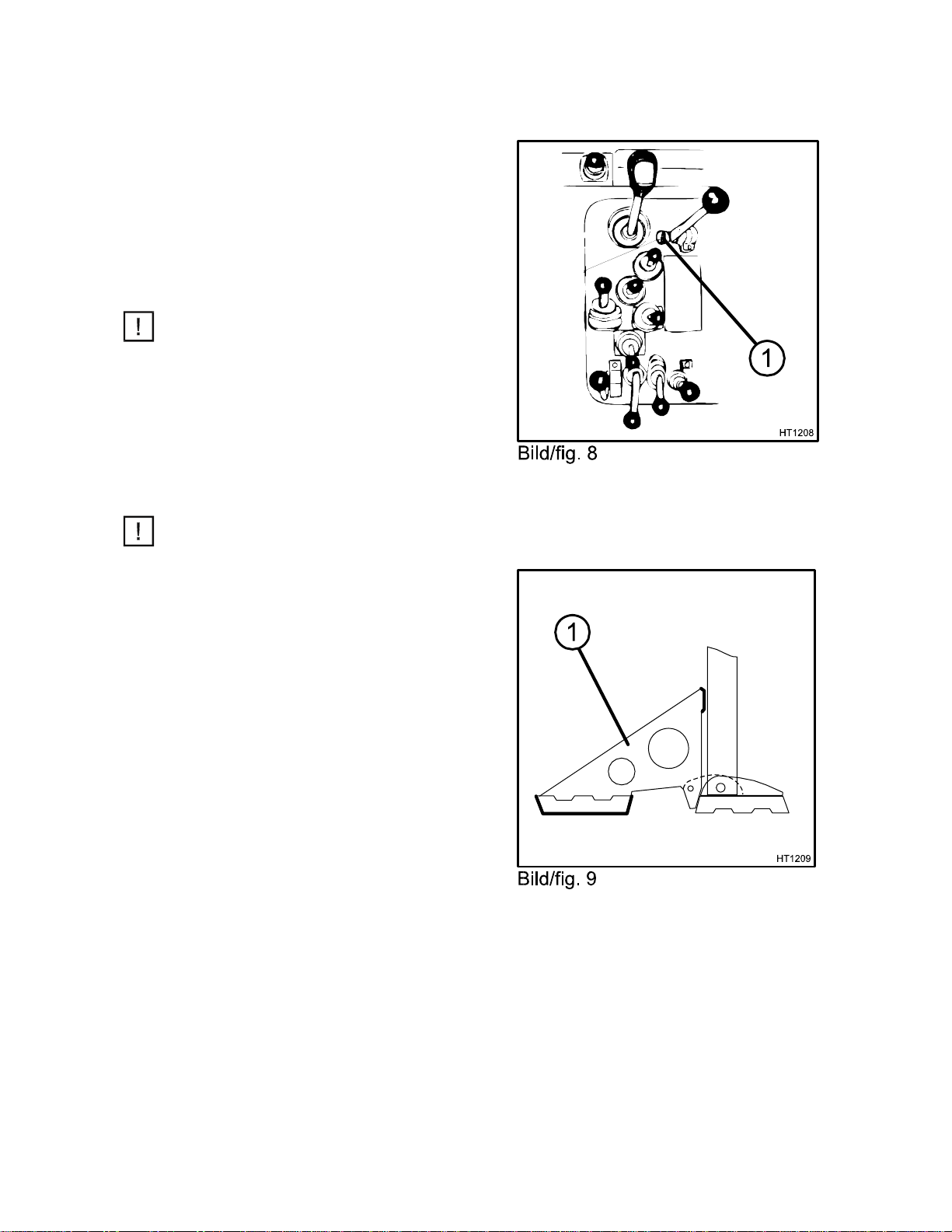

•Switch on the power take-off (8/1) in the

operator’s cab of the Unimog.

•Increase the engine speed through external

hand adjusting lever to nominal speed of 1,550

rpm (approx. ½ gas).

Note

Only switch on power take-off during excavator

operation.

•Stabilising the backhoe excavator

•Release the parking brake of the Unimog.

•Apply the steering lock.

Note

When working with the backhoe excavator

slewed sideways we recommend employing an

additional support in order to improve the

stability of the Unimog with the HT 12 attached.

When the excavator is slewed sideways, the

additional support (9/1) on the supporting foot,

to which the excavator is slewed, must be

employed.

When driving on public roads, the additional

support must be dismounted.

HT 12 Unimog 1.96 13

5.3 Excavator operation

5.3.1 General

The excavator is equipped as standard with ISO control, upon which the following

description is based.

Attention

If the customer so wishes, the excavator may be equipped with a different control.

Your excavator must therefore be checked to see whether or not a different control

is installed. Incorrect operation may endanger persons or objects.

Before commencing work, memorise the lever controls well. Commence at low engine

speed when familiarising yourself with the controls.

5.3.2 Actuation of work equipment

5.3.3 Actuation of stabilisers

14 HT 12 Unimog 1.96

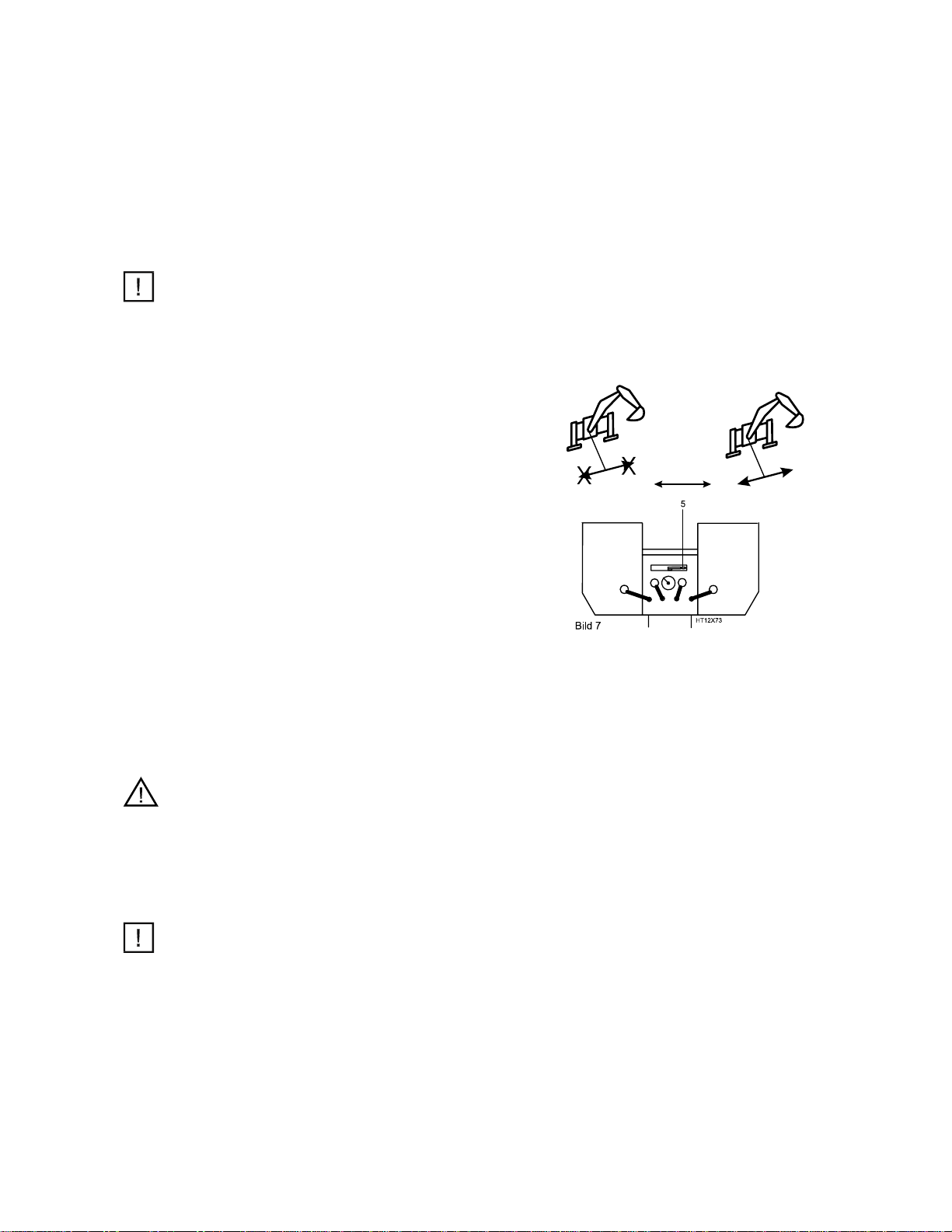

5.4 Lateral adjustment of the work equipment

5.4.1 General

The work equipment can be slewed sideways on the

mounting plate.

This allows accurate and safe work close to walls, e.g.

house walls. Furthermore, the reach of the excavator

can be increased when working across the direction of

travel.

Note

Apply the widened support if necessary.

5.4.2 Loosening and positioning the slide

To do so, the excavator is slewed in the direction of or

against the direction of slewing to the end position and

the ball valve (7/5) is opened.

After the bucket has been lowered to the ground and

the dipperstick actuated, the slide with boom is drawn or

pushed to the desired position.

5.4.3 Clamping the slide

After positioning the slide, the ball valve must be closed

and the actuating lever for „Boom up“ for pressure

build-up in the clamping cylinders must be actuated.

Thus the slide is clamped and the excavator is ready for

operation.

Attention

It is important that the machine is positioned in

exact accordance with these guidelines. Take care

to ensure that the slide is clamped in the proper

manner.

Danger of accident

Note

When working, the ball valve must always be closed

and may only be opened for lateral adjustment.

HT 12 Unimog 1.96 15

5.5 Crane operations

5.5.1 General

Crane operations are the hoisting, transporting and lowering of loads with the aid of a fixing

device (rope, chain, etc.), whereby the assistance of personnel is required to attach and release

the load.

5.5.2 Safety devices

The excavator may only be used for crane

operations when the prescribed safety devices are

present:

- Secure attachment of loading implements

- Table of carrying capacity, see section 5.5.5

- Overload warning device and a hose-rupture

safety valve if the permissible carrying capacity

exceeds 1,000kg.

The load limit is marked on the overload warning

device (7/6)

Danger starting from: 90 bar

5.5.3 Attachment of loads

Note

Loads must be attached in such a way that they cannot slip or fall out.

Possible forms of attachment

•Load hook attached instead of a bucket, etc.

•Hook with safety net welded onto the bucket rod (not possible in the case of quick-mounting

buckets with ejectors).

A suitable, appropriately sized loading implement must be employed for picking up the material

to be lifted.

Always wear protective gloves when working with loading implements.

5.5.4 Attachment and carrying of loads

Attention

Personnel guiding the machine and attaching loads must remain only in the machine

operator’s field of vision.

Personnel attaching loads may only approach the boom from the side and with the machine

operator’s permission. The machine operator may only give his permission if the machine is

standing still and the work equipment is not in motion.

The machine operator must carry loads as close to the ground as possible and prevent them

from swinging.

Machines may only travel with an attached load if the path of travel is fairly even.

16 HT 12 Unimog 1.96

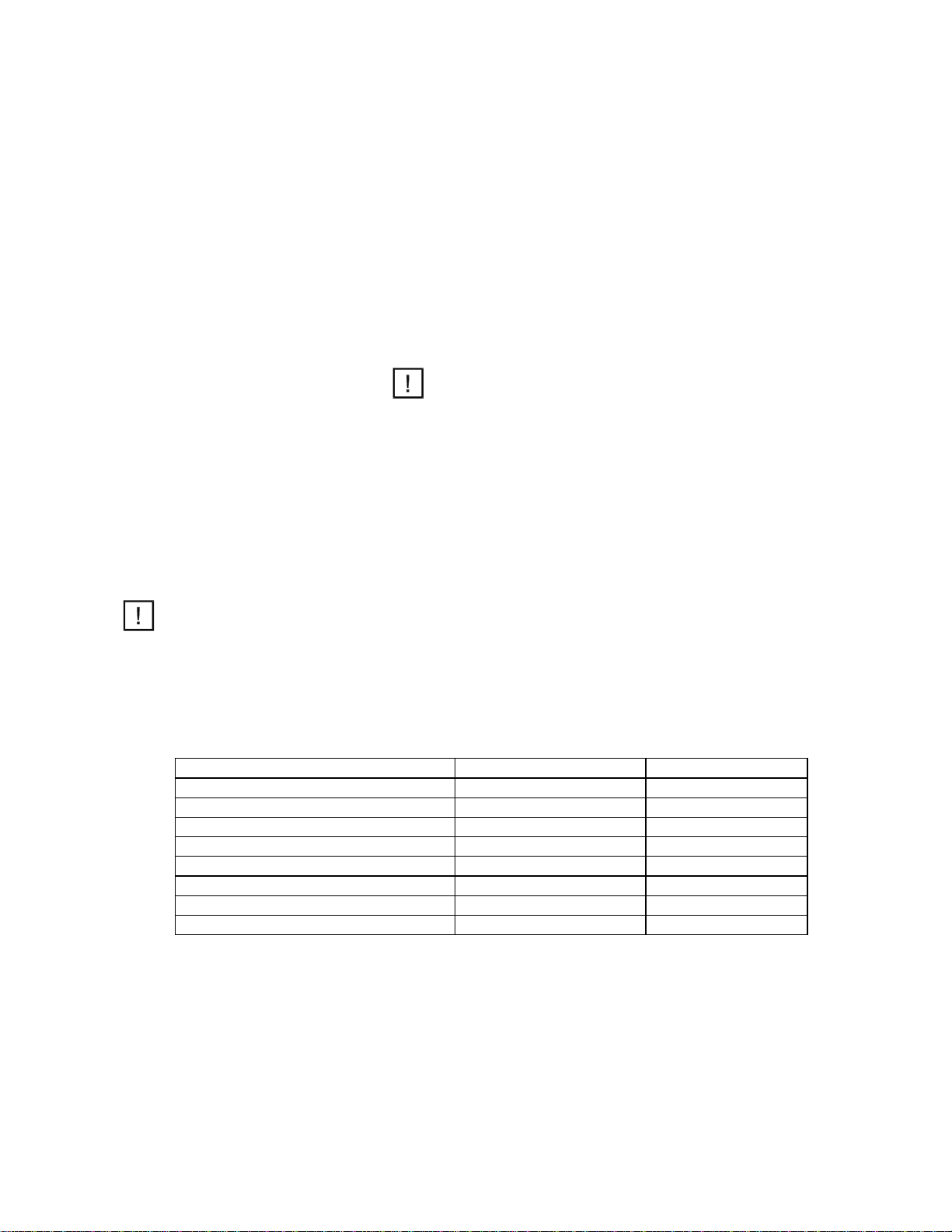

5.5.5 Carrying capacities

with the following equipment:

yWithout bucket, with load hook

yBucket cylinder, rocker arm and bucket rod left on the machine

yMachine supported

Values without brackets :

All values apply for the complete slewing range and include a stability factor of 1.25.

These values are determined according to DIN 15019 page 2 and presented according

to DIN 24083.

Values in brackets :

Values correspond to the hydraulic lifting force and only apply in the longitudinal

direction (vehicle longitudinal axis) with the undercarriage supported.

HT 12 Unimog 1.96 17

5.6 Changing work attachments

5.6.1 General

In order to achieve maximum utilisation of the

machine for a variety of applications, a great

number of work attachments are available.

Attention

When the work attachments have been

removed, they must be secured against tilting

and overturning to avoid possible injuries to

persons.

Note

The hydraulic system must be relieved of

pressure before hydraulic connections are

disconnected.

5.6.2 Assembly of work attachments

Note

The bearings of the work attachment, the

dipperstick and the bucket rod must be free of

dirt.

•Procedure for changing attachments

Lower the work attachment to the ground and

position so that it cannot tilt. Remove the pins

which connect the attachment to the dipperstick

and the bucket rod.

Mount another work attachment.

18 HT 12 Unimog 1.96

6 Transport position when driving on public roads

6.1 Backhoe tilting for transport

Description to be seen in the direction of the backhoe !!

•Move the boom completely to the right and clamp. Fully retract the boom, close the bucket and

retract the dipperstick

•Slew the boom to the inside, secure the dipperstick with a turnbuckle on the mounting plate

•Apply the parking brake, release the steering lock

•Retract the stabilizers

•Fold up the driver’s seat and secure

•Position both lock pins (10/1) between the mounting frame and the mounting device in

position „unlocked“

•Ensure that the bolt (10/2) for transport lock (on the right - in backhoe direction) is in posi-tion

„unlocked“

•Tip the backhoe onto the platform by actuating the tilt cylinder via the valve lever in the Uni-

mog driver’s cab

Attention

People must not remain on the platform.

Danger of injury !

•Position the bolt (10/2) between the mounting frame and the mounting device in position

„locked“ for transport lock.

Note

Some Unimog types are equipped with lock valves for the tilt cylinder. The lock valves are

either to be opened or closed, depending upon the operation.

•Turn off the accessory drive

•Check the vehicle according to the guidelines valid in the user’s country, e.g. Regulations

Authorising the Use of Vehicles for Road Traffic (StVZO) in Germany

•Attach the protection cover for the stabilizer plates

6.2 Changing the backhoe from transport position to working position

The re-positioning is done in reverse order compared to tilting the backhoe for transport:

Attention

The valve for the tilt cylinder (valve lever in the driver’s cab of the Unimog) has to be in neu-tral

position. Ensure that the valve lever is not in floating position

•Remove the protection cover for the stabilizer plates

•Turn on the accessory drive

Note

Some Unimog types are equipped with lock valves for the tilt cylinder. The lock valves are

either to be opened or closed, depending upon the operation

•Position the pin (10/2) between the mounting frame and mounting device in position „unlocked“

•Ensure that both pins (10/1) for the backhoe lock are in position „unlocked“

•Tilt the backhoe to its working position by actuating the tilt cylinder via the valve lever in the

driver’s cab of the Unimog

Attention

People must leave the tilting and slewing area.

Danger of injury !

•Position both lock pins (10/1) between the mounting frame and mounting device in posi-tion

„locked“

•Fold down the driver’s seat and secure

•Extend the stabilizers

•Release the parking brake, apply the steering lock

•Bring the boom to its working position

HT 12 Unimog 1.96 19

fig. 10

20 HT 12 Unimog 1.96

7Care and maintenance

7.1 General notes

The good operating condition and life expectancy of machines are largely influenced by

care and maintenance.

For this reason, it is in every machine owner’s interest to perform the specified

maintenance work and comply with the service intervals. This section deals in detail

with periodic maintenance, inspection and lubricating tasks.

Furthermore, during the warranty period three thorough inspections are stipulated,

which must be carried out by trained specialist personnel.

Type-specific maintenance and inspection plans for this purpose are contained in every

instruction book and every warranty certificate.

Note

Service and wearing parts for inspections should be ordered well in advance!

Inspection intervals

1st inspection - after approx. 100 operating hours

2nd inspection - after approx. 500 operating hours

3rd inspection - after approx.1,000 operating hours

subsequently, every 500 operating hours

Note

The three inspections are obligatory and must be paid for.

If they are omitted, the warranty may be subject to restrictions.

It is essential that the recommendations in chapter 2, “Accident Prevention”, are

observed.

Table of contents

Popular Excavator manuals by other brands

Komatsu

Komatsu PC210-10 DEMOLITION BASE SPEC. Operation & maintenance manual

Hyundai

Hyundai HX140 LC Service manual

Hyundai

Hyundai HX480 L Service manual

RHINOCEROS

RHINOCEROS CTX8010 Operations & parts manual

SUNWARD

SUNWARD SWE90UF-2PB Operation & maintenance manual

Wacker Neuson

Wacker Neuson DW100 Operator's manual