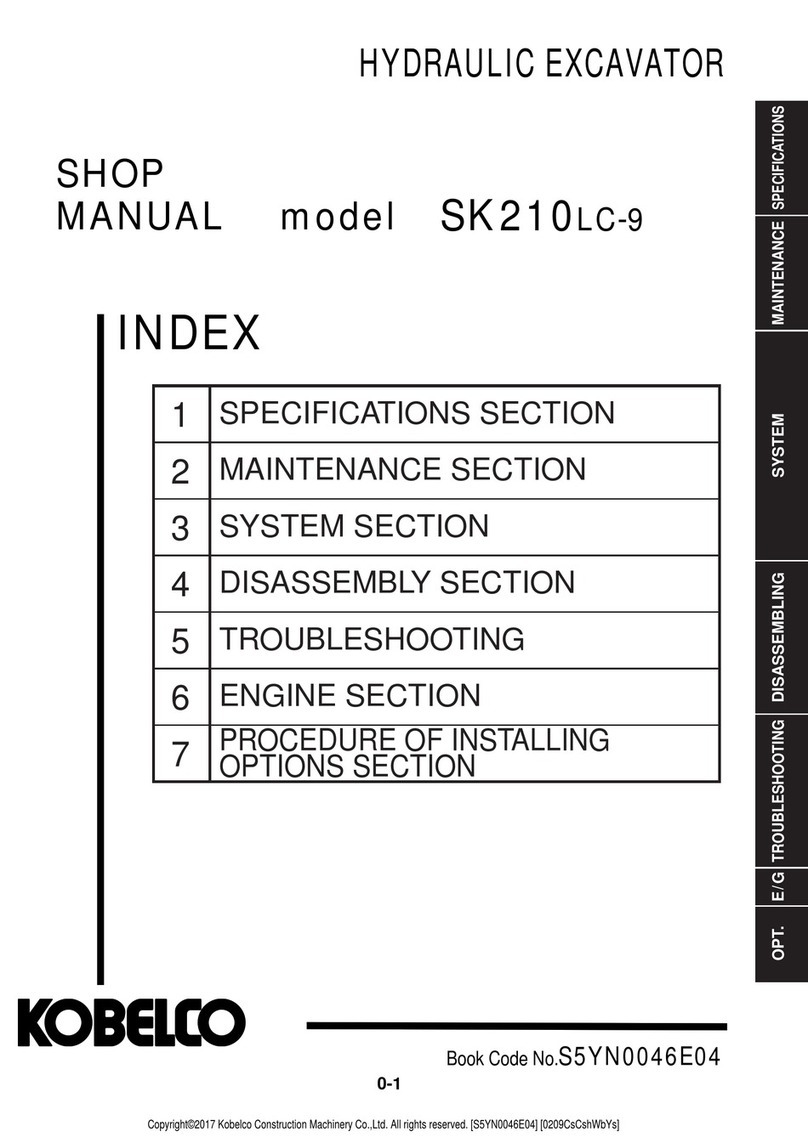

CONTENTS

Foreword

---------------------------------------------------------

0-1

Before servicing this machine

--------------------------

0-2

EC regulation approved

-----------------------------------

0-3

Table to enter S/No and distribution

----------------------

0-4

Safety labels

----------------------------------------------------

0-5

Guide(Direction, S/No, Symbol)

-----------------------

0-11

1. SAFETY HINTS

1. Before operating the machine

--------------------

1-1

2. During operating the machine

--------------------

1-6

3. During maintenance

----------------------------------

1-13

4. Parking

-----------------------------------------------------

1-16

2. SPECIFICATIONS

1. Major components

------------------------------------

2-1

2. Specifications

--------------------------------------------

2-2

3. Working range

-------------------------------------------

2-3

4. Weight

------------------------------------------------------

2-4

5. Lifting capacities

----------------------------------------

2-5

6. Bucket selection guide

-------------------------------

2-7

7. Undercarriage

-------------------------------------------

2-8

8. Specification for major components

-----------

2-9

9. Recommended oils

-----------------------------------

2-12

3. CONTROL DEVICES

1. Cab devices

----------------------------------------------

3-1

2. Cluster

------------------------------------------------------

3-3

3. Switches

---------------------------------------------------

3-7

4. Levers and pedals

-------------------------------------

3-10

5. Air conditioner and heater

--------------------------

3-13

6. Others

-------------------------------------------------------

3-15

4. OPERATION

1. Suggestion for new machine

---------------------

4-1

2. Check before starting the engine

---------------

4-2

3. Starting and stop the engine

----------------------

4-3

4. Operation of the working device

-----------------

4-7

5. T

raveling of the machine

----------------------------

4-8

6. Efficient working method

-------------------------------

4-11

7. Operation in the special work sites

-------------

4-15

8. Normal operation of excavator

-------------------

4-17

9. Attachment lowering

-----------------------------------

4-18

10. Storage

-----------------------------------------------------

4-19

11. RCV lever operating pattern

----------------------

4-21

5. TRANSPORTATION

1. Preparation for transportation

--------------------

5-1

2. Dimension and weight

-------------------------------

5-2

3. Loading the machine

---------------------------------

5-4

4. Fixing the machine

------------------------------------

5-6

5. Loading and unloading by crane

-------------------

5-7

6. MAINTENANCE

1. Instruction

-------------------------------------------------

6-1

2. Tightening torque

--------------------------------------

6-5

3. Fuel, coolant and lubricants

-----------------------

6-8

4. Maintenance check list

------------------------------

6-10

5. Maintenance chart

------------------------------------

6-15

6. Service instruction

-------------------------------------

6-17

7. Electrical system

---------------------------------------

6-34

8. Air conditioner and heater

--------------------------

6-37

7. TROUBLESHOOTING GUIDE

1. Engine

------------------------------------------------------

7-1

2. Electrical system

---------------------------------------

7-2

3 Others

--------------------------------------------------------

7-3

8. HYDRAULIC BREAKER

1. Selecting hydraulic breaker

------------------------

8-1

2. Circuit configuration

-----------------------------------

8-2

3. Maintenance

---------------------------------------------

8-3

4. Precaution when operating the breaker

------

8-4

5. Quick clamp

----------------------------------------------

8-6