Multi function drive unit 2021 1

CONTENTS

1. FOREWORD ........................................................................................................................................ 5

Warning symbols used in this manual ...................................................................................................................................6

2. DESIGNED PURPOSE OF USE.......................................................................................................... 7

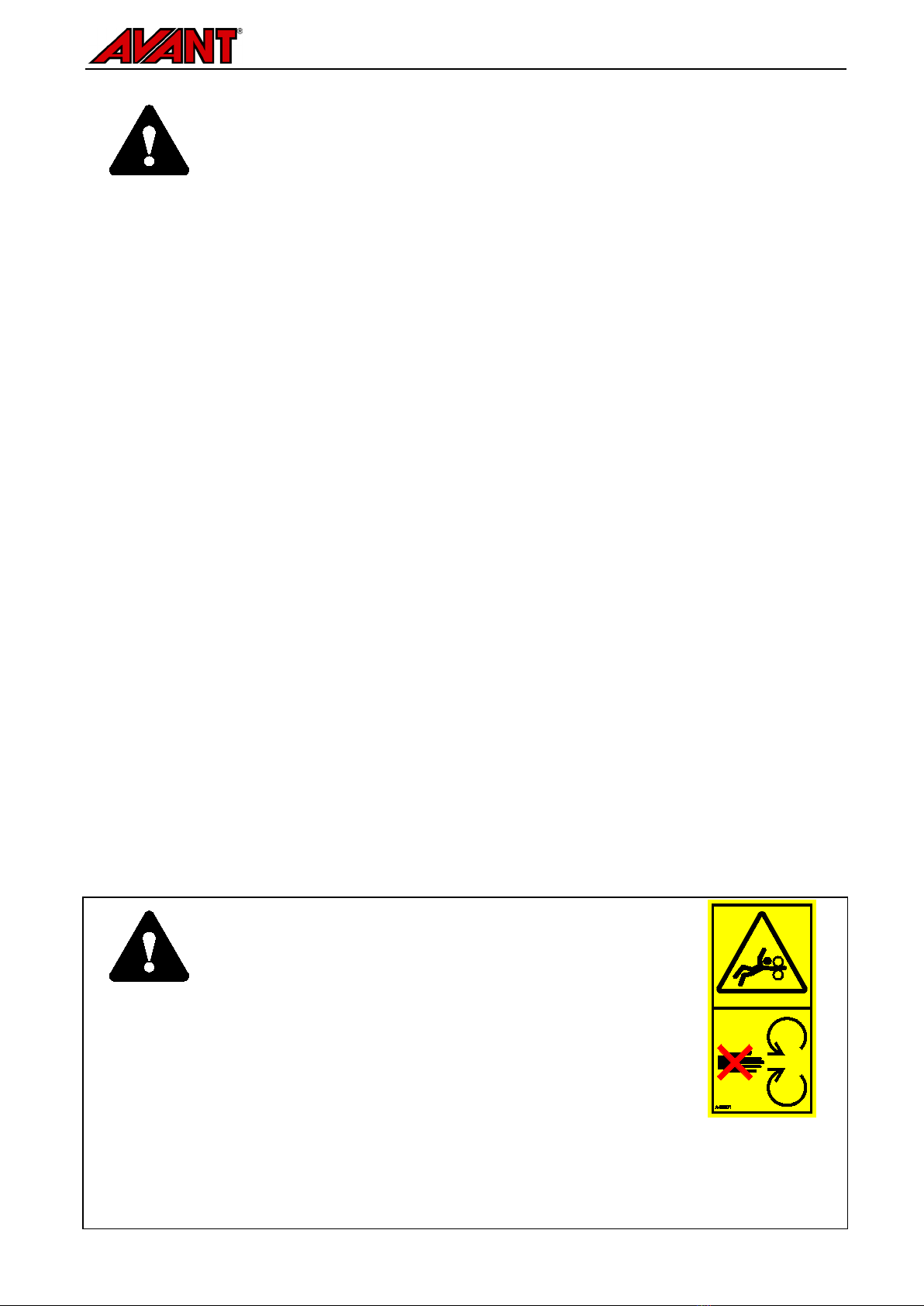

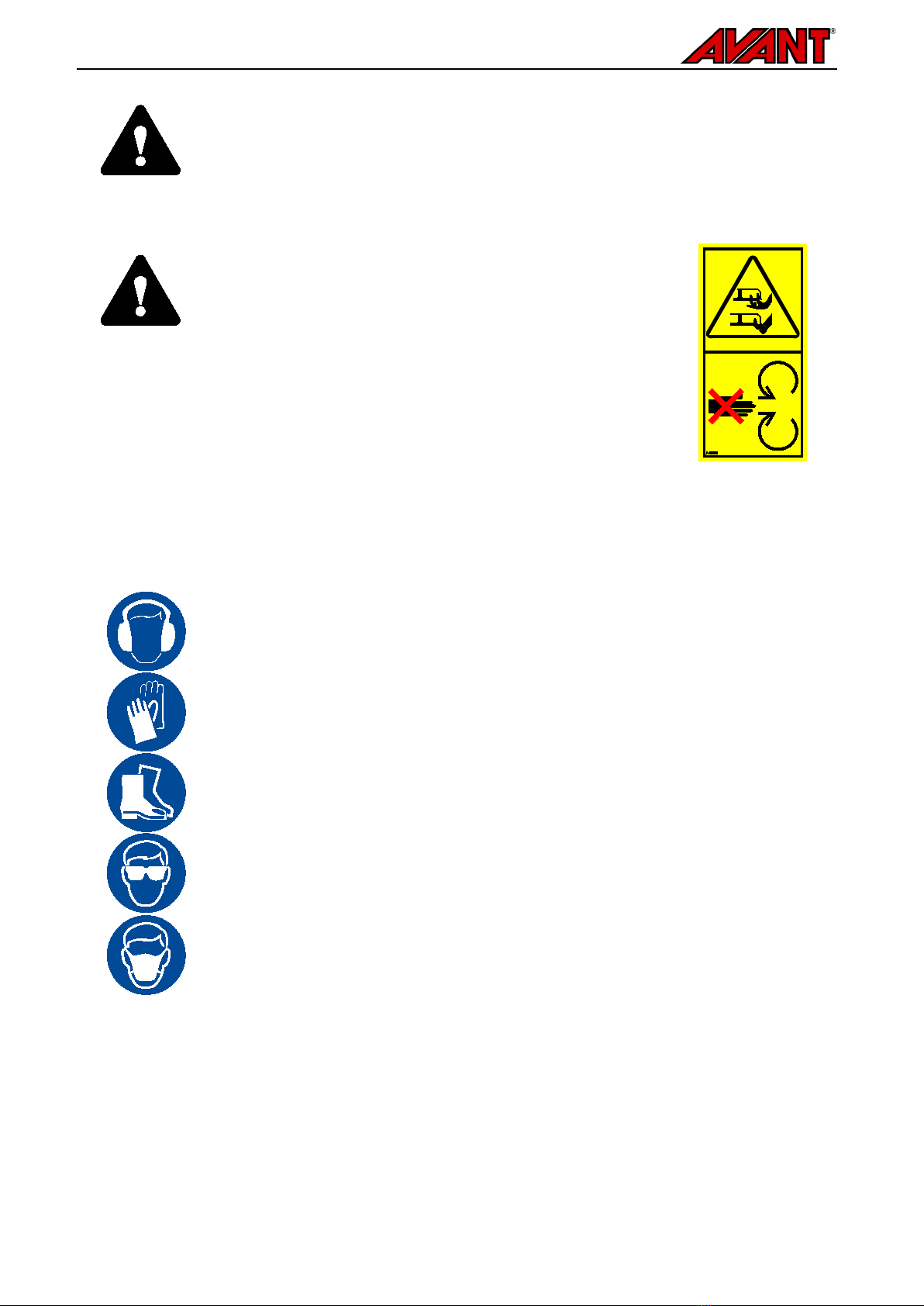

3. SAFETY INSTRUCTIONS FOR USING THE MULTI FUNCTION DRIVE UNIT ........................ 8

4. TECHNICAL SPECIFICATIONS ....................................................................................................... 12

4.1 Rotating speed ............................................................................................................................................................12

4.2 Work tools for the drive unit.................................................................................................................................13

4.3 Safety labels and main components of the attachment ....................................................................................14

5. ASSEMBLING THE ATTACHMENT................................................................................................. 16

5.1 Connecting and disconnecting hydraulic hoses..................................................................................................17

6. OPERATING THE ATTACHMENT .................................................................................................. 19

6.1 Checks before use .....................................................................................................................................................20

6.2 Adjustments.................................................................................................................................................................21

6.2.1 Orientation..........................................................................................................................................................21

6.2.2 Side shift - Angle adapter 90° .........................................................................................................................22

6.2.3 Working on uneven ground............................................................................................................................23

6.3 Transport position .....................................................................................................................................................23

6.4 Storage ..........................................................................................................................................................................24

7. USING THE WORK TOOLS.............................................................................................................. 25

7.1 Changing of work tools ............................................................................................................................................25

7.2 Auger tools ..................................................................................................................................................................26

7.2.1 Using the auger...................................................................................................................................................27

7.3 Concrete mixer ..........................................................................................................................................................31

7.3.1 Storage of the concrete mixer .......................................................................................................................32

7.3.2 Using the concrete mixer................................................................................................................................33

7.3.3 To operate the concrete mixer.....................................................................................................................34

7.3.4 Cleaning of concrete mixer.............................................................................................................................35

7.4 Carousel broom .........................................................................................................................................................36

7.4.1 Using the carousel broom ...............................................................................................................................37

7.4.2 Broom side shift .................................................................................................................................................38

7.4.3 Storage of the carousel broom ......................................................................................................................38

7.5 Rotary hoe ...................................................................................................................................................................39

7.6 Screw pile adapter .....................................................................................................................................................41

7.6.1 Using the screw pile adapter ..........................................................................................................................42

7.7 Log splitter...................................................................................................................................................................43

7.7.1 Using the log splitter.........................................................................................................................................45

7.8 Cable/hose reel...........................................................................................................................................................46

7.8.1 Attaching the cable/hose reel .........................................................................................................................48

7.9 Screening drum...........................................................................................................................................................50

7.9.1 Using the screening drum................................................................................................................................51