degdrive DGI900 User manual

User Manual

DGI900

2

Contents

Preface 1

Chapter 1 Safety Precautions 4

1.1 Unpackage Inspection 4

1.2 Safety Information 4

1.3 General Precautions 8

1.4 Disposal 10

Chapter 2 Models and Specifications 11

2.1 Models 11

2.2 Specifications 12

2.3 Parts of Inverter 15

2.4 Dimensions 16

2.5 Optional Parts 19

Chapter 3 Installation and Wire Connection 23

3.1 Installation 23

3.2 Removing and Mounting Front Cover of Inverter 24

3.3 Wire Connection 24

3.4 Main Circuit Wiring 25

3.5 Basic Wiring Diagram 27

3.6 Control Circuit Terminal Wiring 27

3.7 EMC Installation Instruction 35

3

Chapter 4 Running of Inverter 39

4.1 Running of Inverter 39

4.2 Operation and Using of the Control Panel 42

4.3 Inverter power switch on 49

Chapter 5 Function Code Table 50

Chapter 6 Description of Function Codes 98

6.1 Basic Parameters(Group P0)98

6.2 Start/Stop Control(Group P1)106

6.3 Auxiliary Functions(Group P2)111

6.4 Input Terminals(Group P3)124

6.5 Output Terminals(Group P4)139

6.6 V/F Control Parameter(Group P5)145

6.7 PID Function(Group P6)150

6.8 Operation Panel and Display(Group P7)157

6.9 Motor Parameters(Group P8)160

6.10 Torque Control and Vector Control Parameters (Group P9)163

6.11 Parameter Protection(Group PA)168

6.12 Multi Reference and Simple PLC Function(Group Pb)177

6.13 Communication Parameter (Group PC)180

6.14 Function Code Parameter(Group Pd)180

6.15 Swing Frequency, Fixed Length and Count(Group PE)181

6.16 AI/AO Correction and AI Curve Setting(Group PF)184

6.17 User Defined Function Codes(Group E0)188

6.18 Motor 2 to Motor 4 Parameters(Group E3、E4、E5)189

6.19 Standard Monitoring Parameters(Group b0)189

Chapter 7 Troubleshooting 190

7.1 Fault Alarm and Troubleshooting 190

4

7.2 Fault Record Search 195

7.3 Fault Reset 195

Chapter 8 Preservation and Maintenance 196

8.1 Preservation and Maintenance 196

8.2 Periodic Preservation and Maintenance 196

8.3 Warranty of Inverter 197

Chapter 9 Serial port RS485 communication protocol 199

9.1 Communication overview 199

9.2 Communication protocol specification 199

9.3 RTU protocol 200

5

Chapter 1 Safety Precautions

Unpackage Inspection

Upon unpacking, check:

• Whether the nameplate model and AC drive ratings are consistent with your order. The box

contains the AC drive, certificate of conformity, user manual and warranty card.

• Whether the AC drive is damaged during transportation. If you find any omission or

damage, contact your supplier immediately.

Voltage Code

220V 2

380V 4

Input voltage Code

Single phase S

Three phases T

Code Inverter type

GConstant torque

PPump& Fan

Abbreviation

DGI900 - 4 T 0015 G

Code Power rate

0007 0.75KW

0015 1.5KW

0075 7.5KW

6

1.2 Safety Information

The use phase Safety class Precaution

Before

Installation Danger

Do not install the product if the package is with ◆

water, or component is missing or broken.

Do not install the product if the label on the ◆

package is not identical to that on the inverter.

Caution

Be careful of carrying or transportation. Risk of ◆

devices damage.

Do not use damaged product or the inverters ◆

missing component .Risk of injury.

Do not touch the parts of control system with ◆

bare hands. Risk of ESD hazard.

Installation

Danger

Installation base shall be metal or other non◆

flammable material. Risk of fire.

Do not install inverter in an environment ◆

containing explosive gases, otherwise there is

danger of explosion.

Do not unscrew the fixing bolts, especially the ◆

bolts with red mark.

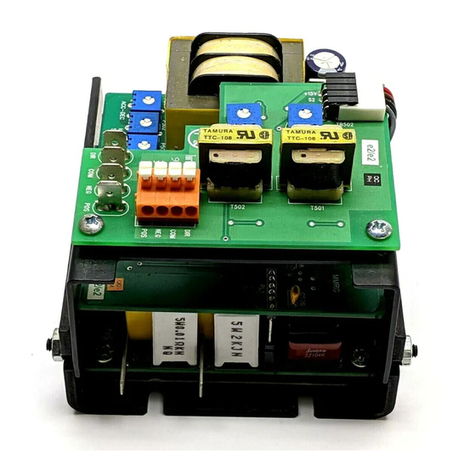

Fig 1 1. Models description

7

Caution

Do not leave cable strips or screws in the◆

inverter. Risk of inverter damage.

Install the product at the place with less◆

vibration and no direct sunlight.

Consider the installation space for cooling◆

purpose when two or more inverters are placed in

the same cabinet.

8

Wiring

Danger

Wiring must be performed by authorized and ◆

qualified personnel. Risk of danger.

Circuit breaker should be installed between ◆

inverter and the mains. Risk of fire.

Make sure the input power supply has been ◆

completely disconnected before wiring. Failure to

comply may result in personnel injury and/or

equipment damage.

Since overall leakage current of this equipment ◆

may be bigger than 3.5mA, for safety's sake, this

equipment and its associated motor must be well

grounded so as to avoid risk of electric shock.

Never connect the power cables to the output ◆

terminals (U, V, W) of the AC drive. Pay attention

to the marks of the wiring terminals and ensure

correct wiring. Failure to comply will result in

damage to the AC drive.

Install braking resistors at terminals (P+)and ◆

(P or PB) only. Failure to comply may result in

equipment damage.

9

Caution

Since all adjustable frequency AC drives from ◆

our company has been subjected to hi pot test

before delivery, users are prohibited from

implementing such a test on this equipment.

Failure to comply may result in equipment

damage.

Signal wires should to the best of the possibility◆

be away from main power lines. If this cannot be

ensured, vertical cross arrangement shall be

implemented, otherwise interference noise to

control signal may occur.

If motor cables are longer than 100m, it is ◆

recommended output AC reactor be used. Failure

to comply may result in faults.

Before Power

on Danger

Inverter shall be power on only after the front ◆

cover is assembled. Risk of electrical hazard.

Caution

Verify that the input voltage is identical to the ◆

rated voltage of product, correct wiring of input

terminals R, S, T and output terminals U, V, and

W, wiring of inverter and its peripheral circuits,

and all wires should be in good connection. Risk

of inverter damage.

10

After Power on

Danger

Do not open the cover after power. Rick of◆

electrical hazard.

Do not touches any input/output terminals of◆

inverter with bare hands. Rick of electrical hazard.

Caution

If auto tuning is required, be careful of personal◆

injury when motor is running. Risk of accident.

Do not change the defaults of parameters. Risk◆

of devices damage.

During

Operation Danger

Non professionals shall not detect signals◆

during operation. Risk of personal injury or device

damage.

Do not touch the fan or the discharging resistor◆

to check the temperature. Failure to comply will

result in personal burnt.

Caution

Prevent any foreign items from being left in the ◆

devices during operation. Risk of device damage.

Do not control start/stop of inverter by ON/OFF ◆

of contactor. Risk of device damage.

Maintenance

Danger

Maintenance and inspection can only be◆

performed by professionals. Risk of

personal injury.

Maintain and inspect devices after ◆

power is off. Risk of electric hazard.

Repair or maintain the AC drive only ten ◆

minutes after the AC drive is powered off.

This allows for the residual voltage in the

11

capacitor to discharge to a safe value.

Failure to comply will result in personal

injury.

All pluggable components can be ◆

inserted or pulled out only when power has

been turned off.

Set and check the parameters again ◆

after the AC drive is replaced.

General Precautions

1. Constant torque low frequency running

When inverter with induce motor running at long time low speed, the effection of heat

emission will get worse and influence motor using life. If low speed constant torque running

for long time, user have to use Variable frequency motor.

2. Motor insulation test

Perform the insulation test when the motor is used for the first time, or when it is re used

after being stored for a long time, or in a regular check up, in order to prevent the poor

insulation of motor windings from damaging the AC drive. The motor must be disconnected

from the AC drive during the insulation test.

3. Hoist load

In Hoist load application, as the inertia exist, inverter will trip as over current or overvoltage

fault. In the case, braking unit and resistor should be connected.

4. Vibration of mechanical device

12

The AC drive may encounter the mechanical resonance point at some output frequency,

which can be avoided by setting the skip frequency.

5. Voltage sensitive device or capacitor on output side of the AC drive

Do not install the capacitor for improving power factor or lightning protection voltage

sensitive resistor on the output side of the AC drive because the output of the AC drive is

PWM wave. Otherwise, the AC drive may suffer transient overcurrent or even be damaged.

M

变频调速器

U

V

W

KM

6. Derate at Basic frequency setting

When basic frequency is lower than rated frequency, be caution to derate motor avoilding

motor burn.

7. Running at over 50 Hz

If the AC drive is required to run at over 50 Hz, motor viberation and noise will increase.

Consider the capacity of the machine.

8. Thermal protection of motor

AC DRIVE

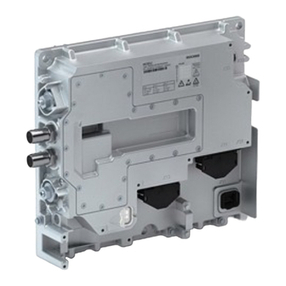

Fig 1 2. Inverter not allowed to connect capacitor

13

If the rated capacity of the motor selected does not match that of the AC drive,

especially when the AC drive's rated power is greater than the motor's, adjust the motor

protection parameters on the operation panel of the AC drive or install a thermal relay in the

motor circuit for protection.

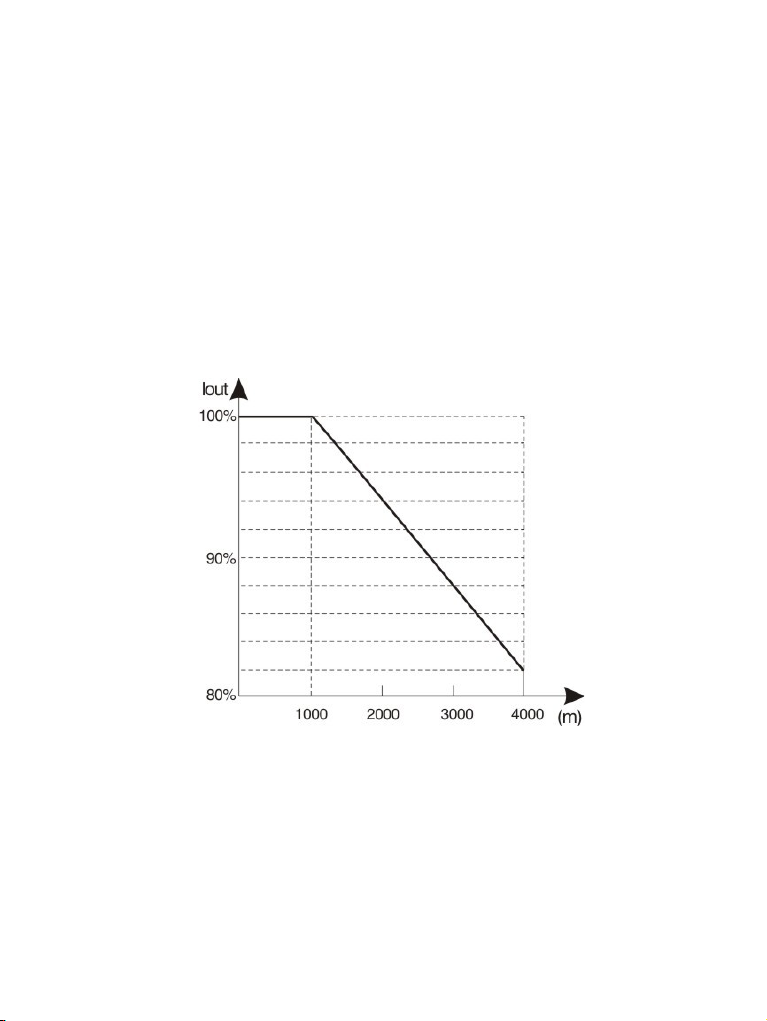

9. Altitude and de rating

In places where the altitude is above 1000 m and the cooling effect reduces due to thin air, it

is necessary to de rate the AC drive.

10. Protection class

DGI900 protection level is IP20 when inverter with keypad.

Fig 1 3. Inverter output current derating and Altitude

14

Disposal

The electrolytic capacitors on the main circuits and PCB may explode when they are burnt.

Poisonous gas is generated when the plastic parts are burnt. Treat them as ordinary

industrial waste.

15

Chapter 2 Models and Specifications

2.1 Models

DGI900 series inverter has 2 kinds of voltage levels, 220V and 380V. The Power range is

from 0.4KW to 450KW. Models of DGI900 series are shown in Table 2 1.

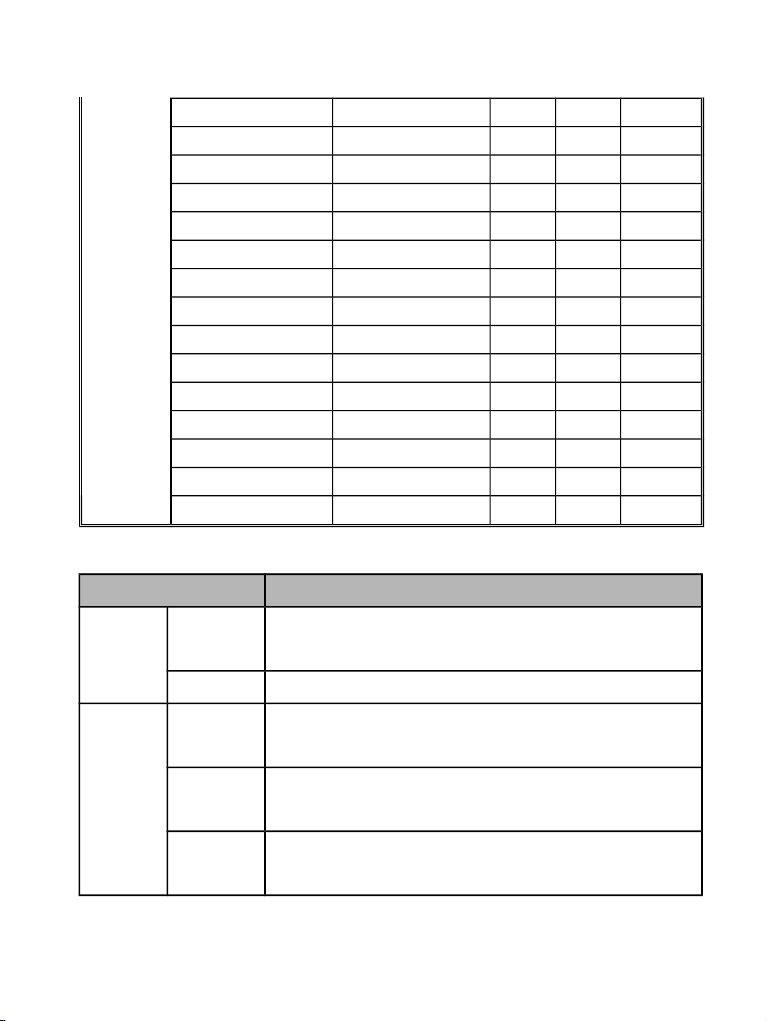

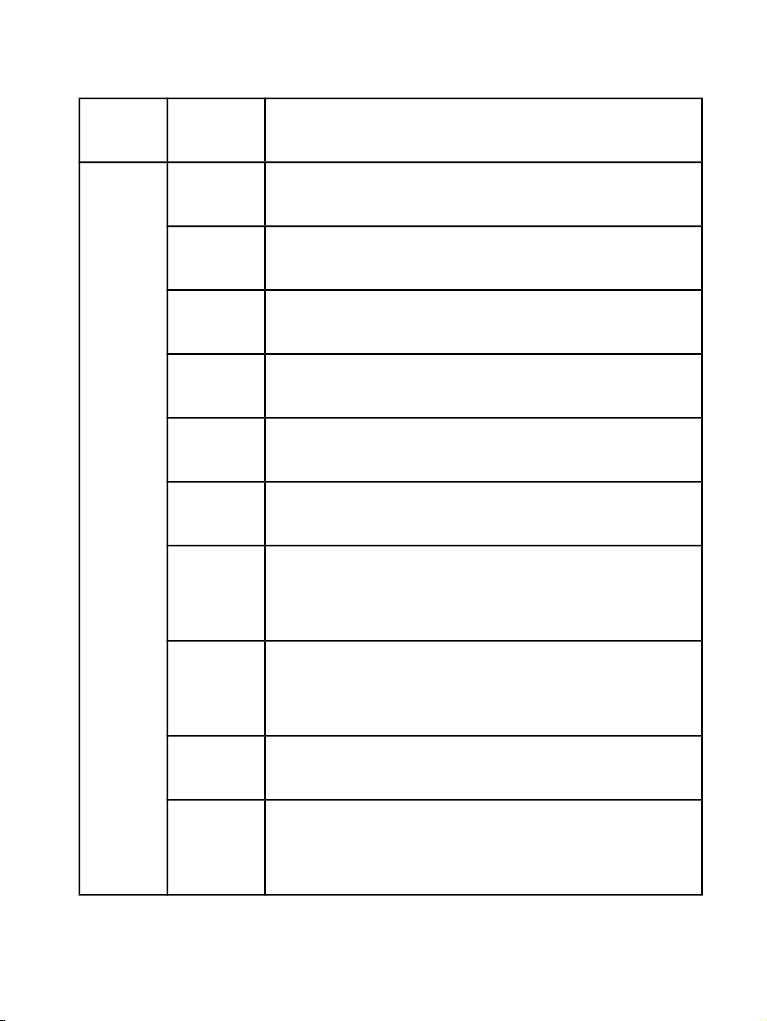

Table 2 1. Models description

Voltage level Models Rated

capacity(

Rated

output

Applicable

motor(KW)

220V

Single

phase

DGI900 2S0004G

1.1

3.0

0.4

DGI900 2S0007G

1.5

4.7

0.75

DGI900 2S0015G

2.8

7.5

1.5

DGI900 2S0022G

3.8

10.0

2.2

220V

Three phase

DGI900 2T0015G

3.0

7.0

1.5

DGI900 2T0022G

4.0

10.0

2.2

380V

Three phase

DGI900 4T0007G

1.5

2.5

0.75

DGI900 4T0015G

2.5

4.0

1.5

DGI900 4T0022G

DGI900 4T0022P

3.0

6.0

2.2

DGI900 4T0037G

DGI900 4T0037P

5.9

9.6

3.7

DGI900 4T0055G

DGI900 4T0055P

8.5

14.0

5.5

DGI900 4T0075G

DGI900 4T0075P

11

17.0

7.5

DGI900 4T0110G

DGI900 4T0110P

17

25

11

DGI900 4T0150G

DGI900 4T0150P

21.7

32

15

DGI900 4T0185G

DGI900 4T0185P

25.7

39

18.5

DGI900 4T0220G

DGI900 4T0220P

29.6

45

22

DGI900 4T0300G

DGI900 4T0300P

39.5

60

30

DGI900 4T0370G

DGI900 4T0370P

49.4

75

37

DGI900 4T0450G

DGI900 4T0450P

60

91

45

16

DGI900 4T0550G

DGI900 4T0550P

73.7

112

55

DGI900 4T0750G

DGI900 4T0750P

99

150

75

DGI900 4T0900G

DGI900 4T0900P

116

176

90

DGI900 4T1100G

DGI900 4T1100P

138

210

110

DGI900 4T1320G

DGI900 4T1320P

167

253

132

DGI900 4T1600G

DGI900 4T1600P

200

304

160

DGI900 4T1850G

DGI900 4T1850P

234

355

187

DGI900 4T2000G

DGI900 4T2000P

248

377

200

380V

DGI900 4T2200G

DGI900 4T2200P

280

426

220

Three phase

DGI900 4T2500G

DGI900 4T2500P

318

474

250

DGI900 4T2800G

DGI900 4T2800P

342

520

280

DGI900 4T3150G

DGI900 4T3150P

390

600

315

DGI900 4T3500G

DGI900 4T3500P

435

660

350

DGI900 4T4000G

DGI900 4T4000P

493

750

400

DGI900 4T4500G

DGI900 4T4500P

560

850

450

2.2 Specifications

Items Specifications

Input Rated

Voltage

Single phase220V, three phase 220V, three phase

380V;50Hz/60Hz

Range Voltage: ±20% voltage unbalance rate:<3%; frequency: ±5%

Output Rated

voltage

0~200V/220V/380V

Frequency

range

0Hz~500Hz

Frequency

resolution

0.01Hz

17

Overload

ability

150% rated current for1minute, 180% rated current for3 seconds

Control function

Modulation

modes

Optimized space voltage vector SVPWM modulation

Control

mode

V/F, Sensor less vector and Closed loop vector control

Frequency

accuracy

Digital setting: The highest frequency×± 0.01% Analog

setting: The highest frequency ×±0.2%

Frequency

resolution

Digital setting: 0.01Hz; Analog setting: The highest frequency×

0.1%

Start

frequency

0.40Hz~20.00Hz

Torque

boost

Auto torque boost, manual torque boost 0.1%~30.0%

V/F curve Five ways: constant torque V/F curve, 1 kind of user defined

V/F curve ,3 kinds of down torque curve(2.0/1.7/1.2times the

power)

Acc./Dec.

curve

Two ways: linear Acc./Dec.,S curveAcc./Dec.;7 kinds of

Acc./Dec. time,

Time unite (minute/second) optional, max time: 6000 minutes.

DC braking DC braking start frequency:0~15.00Hz

braking time:0~60.0s braking current:0~80%

Energy

consuming

braking

Below 22KW drive built in energy consuming braking unit, 30

37KW built in braking unit optional, external braking resistor is

optional.

18

Control

function

Jog

running

Jog frequency range:0.1Hz~50.00Hz, JOG Acc./Dec. time:

0.1~60.0s

PI built in Easily constitute a close loop control system

Multi stage

speed

running

Multi stage speed running available through built in PLC or

control terminals

Textile

swing

frequency

Swing frequency available with preset and central frequency

adjustable

Auto

voltage

regulation

Keep a stable voltage automatically when the grid voltage

transients

Auto

energy

saving

running

Saving energy by auto optimizing V/F curve according to the

load

Auto

current

limiting

Auto current limiting to prevent frequent over current fault trip

Multi

pumps

control

With water supply card, the function can implement multi pumps

constant pressure water supply

Communic

ation

4 field bus: Modbus, Profibus, CANlink, CANopen

19

Running

function

Running

command

channel

Control panel : control terminal :serial port :3 channels

switchable

Frequency

setting

channel

Control panel potentiometer setting: ▲ ▼、control panel keys

setting; Function code setting: Serial port setting; Terminal

up/down setting: Input Analog voltage setting: Input Analog

current setting: Input pulse setting; Combination ways setting;

Above ways are switchable.

Switch

input

channel

FWD/REV command: 8channels programmable switch inputs,

35kinds of function can be set separately

Analog

input

channel

4~20mA: 0 10V: 2 optional analog inputs

Analog

output

channel

4~20mA or 0~10V optional, setting frequency and output

frequency ,etc feature output

Switch/puls

e output

channel

2 channels Programmable open collectors output, 2 channels

relays output, 1 channel 0~20KHz pulse output

Control panel

LED digital

display

Display setting frequency, output voltage, output current, etc.

External

meter

display

Display output frequency, output current, output voltage, etc.

Key lock All the keys can be locked

20

Parameter

copy

Function code parameters are able to be copied between

inverters when use remote control panel。

Protection function Overcurrentprotection:overvoltageprotection:undervoltageprotec

tion:overheating protection: overload protection, etc.

Optional parts Braking unit: remote control panel: cable: panel mounting feet,

etc.

Environment

Environment Indoors, free from direct sunlight, dust, corrosive gas, oil mist,

steam, water dropper salt, etc

Altitude Lower than 1000m (derating is necessary above 1000m)

Ambient

temperature

-10℃~+40℃

Humidity <95%RH, no condensation

Vibration Lower than 5.9m/s (0.6g)

Storage

temperature

-20℃~+60℃

Structure Protection

level

IP20(In the selection of state display unit or the keyboard

state)

Cooling Forced air cooling

Installation Wall mounted; Floor mounted

Other manuals for DGI900

1

Table of contents

Other degdrive DC Drive manuals

Popular DC Drive manuals by other brands

Bosch

Bosch REXROTH HYDROTRAC GFT 8000 operating instructions

Siemens

Siemens SINAMICS S120 Getting started

HAUTAU

HAUTAU SM 101 Installation and operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 755 Original instructions

Idex

Idex MICROPUMP EAGLEDRIVE EMSN Series Installation, operation and warranty information

Siemens

Siemens 3TL60 operating instructions