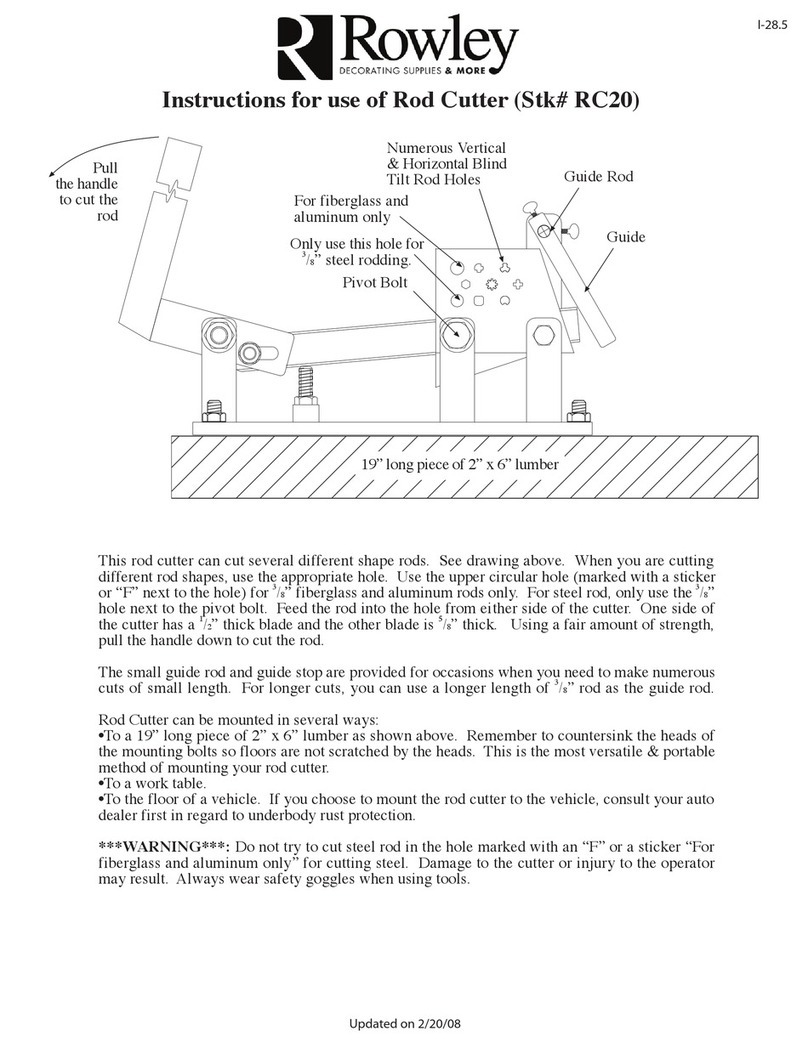

Instruction on Electric Rotary Cutter

Caution

Please read these instructions carefully before using your electric rotary cutter. Unplug the power cable

from the power source before you perform any adjustment or maintenance on the cutter. Unplug the power

cable when the cutter is not in use. You should handle your cutter with extreme caution because of the

sharp blade. When using, make sure the cord is always behind the cutter.

Specification

Voltage: 110 V Power: 56 W

Max. Cutting Thickness: 5/16”Weight: 1.9 Ib

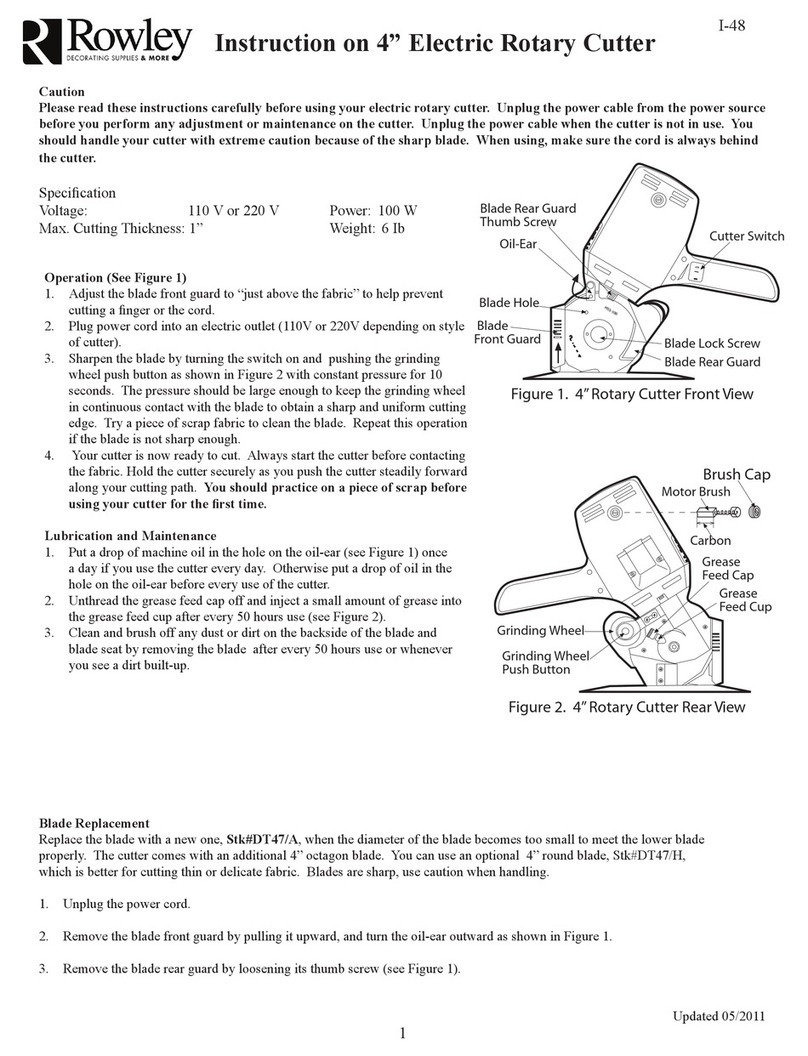

Operation (See Figure 1)

Adjust the blade guard to “just above the fabric” to help prevent accidentally

cutting the cord. Plug cord into an electric outlet (110V). Turn on the

cutter by squeezing and holding the switch bar. Always start the cutter

before contacting the fabric. Hold the cutter securely as you move steadily

forward along your desired cutting path. Practice on a piece of scrap

fabric before using your cutter for the first time.

1/2

Blade Sharpening (see Figure 2)

1.Put one drop of machine oil on the surface of the sharpening stone.

2.Connect the power cable to an electric outlet (110V).

3.Squeeze and hold the switch bar with your left hand to turn the cutter on.

4.Use your finger to press lightly on the sharpener button with constant pressure

for 5 seconds. The pressure should be large enough to keep the sharpening

stone in continuous contact with the blade to obtain a sharp, uniform edge.

Repeat this operation if the blade is not sharp enough. Note: Excessive sharpening

will reduce blade life.

Blade replacement (see figure 3)

Replace the blade with a new one when the

diameter of the blade becomes too small to

meet the lower blade properly. Blade is sharp,

use caution when handling.

1.Unplug the power cord.

2.Turn the oil-ear outward.

3.Insert the tail end of a 7/64”diameter drill

bit through the hole in the blade until it

contacts the cutter head as shown in Figure

3A.

4.Turn the blade lock screw counter clockwise

to loosen.

5.Push the lower blade up by using the index

finger of your left hand, and take the worn

blade out as shown in Figure 3B.

6.Push the lower blade up, and insert the new

Turn the oil-ear outward

insert the drill bit

into the blade hole

A. B.

Figure 3. Blade Replacement

oil hole B

Figure 4. Lubrication

blade guard lock screw

blade guard adjustment

Figure 1. Electric Rotary Cutter

oil-ear

switch bar

cutter head

Push the lower blade up

notches

blade lock screw

oil hole A push button

Updated on January 20, 2008 230 Meek Road Gastonia, NC 28056, Ph: 800-343-4542

cutter body

Figure 2. Blade Sharpening

press sharpening button

sharpening stone

oilling surface

rotary blade in place. The flat side of the blade goes against the cutter head.

Make sure the notches on the blade fit into the base.

7.Insert the tail of a drill bit into the hole in the blade, and tighten the blade

lock screw.

Lubrication and Maintenance

1.Add a drop of machine oil in the hole on the oil-ear (see Figure 1) and oil

hole “A” (see Figure 4) once a day if you use the cutter every day. Otherwise

add a drop before every use of the cutter.

2.Inject a small amount of grease into the oil hole “B” (see Figure 4) once a

month for occasional users, or once every two weeks for heavy use.

3.Clean and brush off any dust or dirt o back side of the blade and cutter bottom

by taking the blade out once a week or whenever you see a dirt build-up.

I-3A