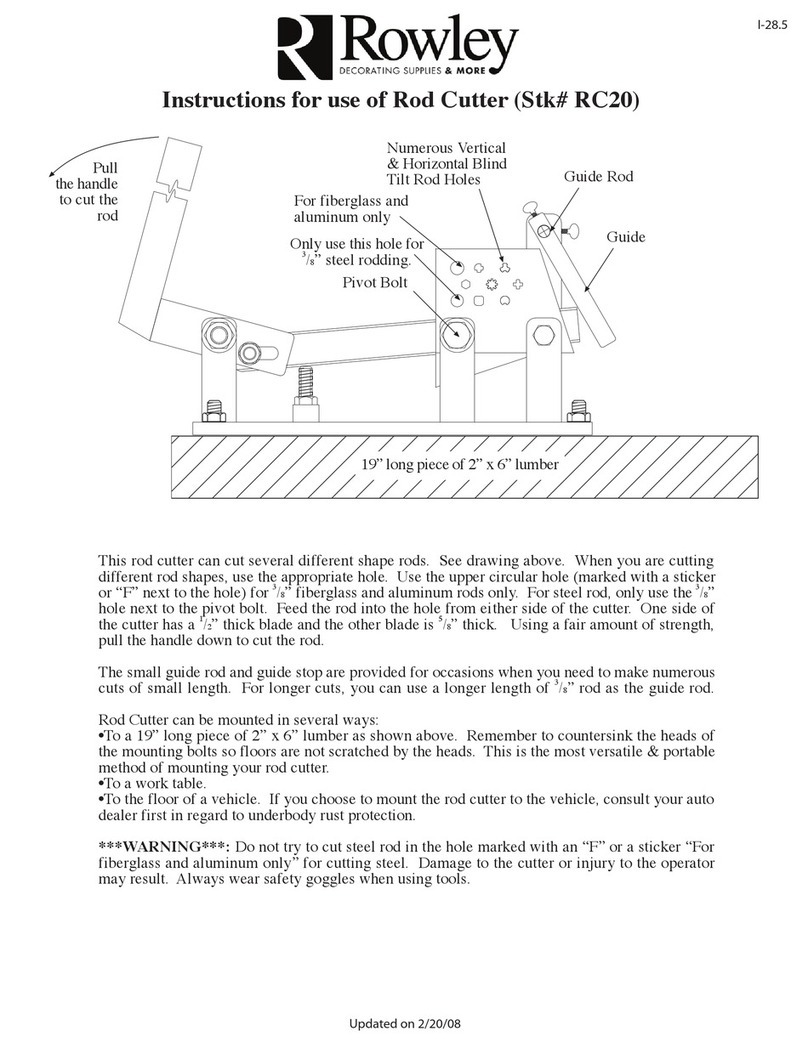

1

Instruction on 4” Electric Rotary Cutter

I-48

HSS-100

Blade

Front Guard

Cutter Switch

Blade Rear Guard

Oil-Ear

Blade Rear Guard

Thumb Screw

Blade Hole

Figure 1. 4” Rotary Cutter Front View

Blade Lock Screw

Caution

Please read these instructions carefully before using your electric rotary cutter. Unplug the power cable from the power source

before you perform any adjustment or maintenance on the cutter. Unplug the power cable when the cutter is not in use. You

should handle your cutter with extreme caution because of the sharp blade. When using, make sure the cord is always behind

the cutter.

Specication

Voltage: 110 V or 220 V Power: 100 W

Max. Cutting Thickness: 1” Weight: 6 Ib

Operation (See Figure 1)

Adjust the blade front guard to “just above the fabric” to help prevent 1.

cutting a nger or the cord.

Plug power cord into an electric outlet (110V or 220V depending on style 2.

of cutter).

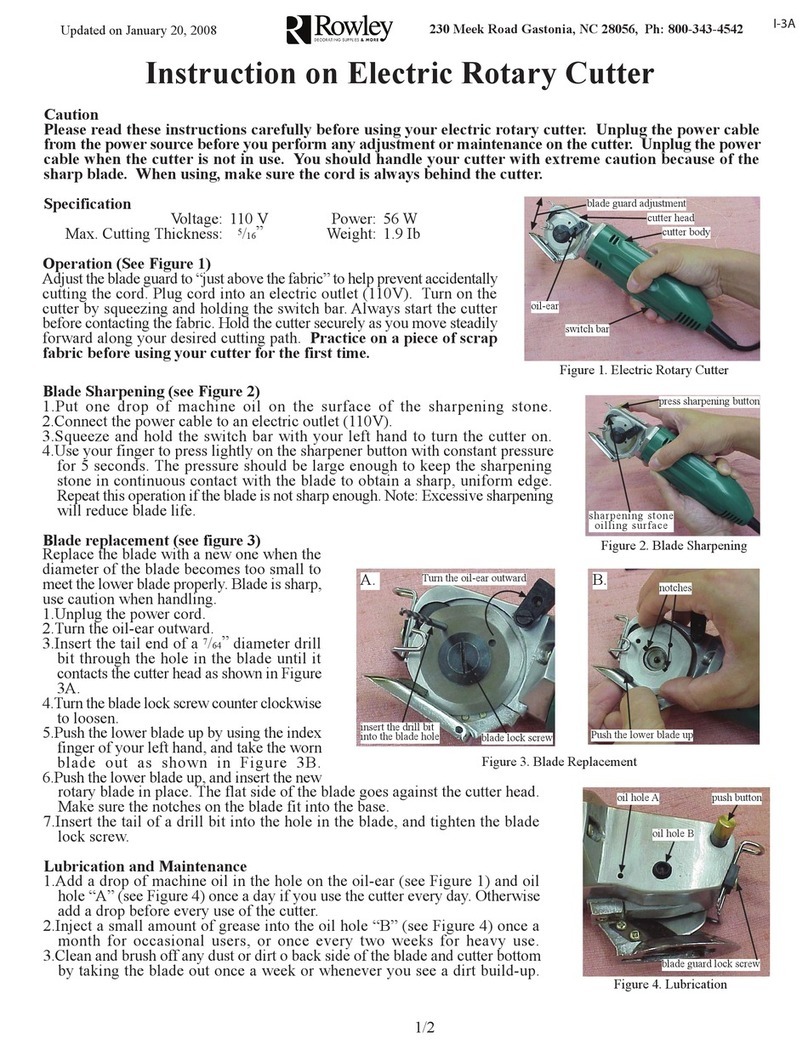

Sharpen the blade by turning the switch on and pushing the grinding 3.

wheel push button as shown in Figure 2 with constant pressure for 10

seconds. The pressure should be large enough to keep the grinding wheel

in continuous contact with the blade to obtain a sharp and uniform cutting

edge. Try a piece of scrap fabric to clean the blade. Repeat this operation

if the blade is not sharp enough.

Your cutter is now ready to cut. Always start the cutter before contacting 4.

the fabric. Hold the cutter securely as you push the cutter steadily forward

along your cutting path. You should practice on a piece of scrap before

using your cutter for the rst time.

Lubrication and Maintenance

Put a drop of machine oil in the hole on the oil-ear (see Figure 1) once 1.

a day if you use the cutter every day. Otherwise put a drop of oil in the

hole on the oil-ear before every use of the cutter.

Unthread the grease feed cap off and inject a small amount of grease into 2.

the grease feed cup after every 50 hours use (see Figure 2).

Clean and brush off any dust or dirt on the backside of the blade and 3.

blade seat by removing the blade after every 50 hours use or whenever

you see a dirt built-up.

Grinding Wheel

Grinding Wheel

Push Button

Grease

Feed Cup

Figure 2. 4” Rotary Cutter Rear View

Grease

Feed Cap

Motor Brush

Carbon

Brush Cap

Blade Replacement

Replace the blade with a new one, Stk#DT47/A, when the diameter of the blade becomes too small to meet the lower blade

properly. The cutter comes with an additional 4” octagon blade. You can use an optional 4” round blade, Stk#DT47/H,

which is better for cutting thin or delicate fabric. Blades are sharp, use caution when handling.

Unplug the power cord.1.

Remove the blade front guard by pulling it upward, and turn the oil-ear outward as shown in Figure 1.2.

Remove the blade rear guard by loosening its thumb screw (see Figure 1).3.

Updated 05/2011