SUBJECT: GIII Controller Chute Sensor Adjustment

MODELS: All GIII / GIII Plus models

TOOLS REQUIRED: Flat screwdriver

ESTIMATED TIME: <2 minutes

ANY QUESTIONS? CONTACT ROYAL VENDORS’ CUSTOMER SERVICE DEPARTMENT

IN NORTH AMERICA, CALL TOLL FREE 1 800 931 9214

F0019077.FRM REV.: A

ISSUE DATE: 23 MAR 2000 REV. DATE: 23 MAR 2000

078

INFORMATION: This document describes the correct procedure

for adjusting the sensitivity of the chute sensor on venders with GIII controllers.

R

Page: 1 of 2

Date: 22 Dec 2015

Revision: 00

Number of

People

Required

426 Industrial Boulevard • Kearneysville WV 25430-2776 • USA

Toll-free in North America: 1 800 931 9214 • Fax: +1 304 725 4016

Canada: +1 905 738 5777 • Mexico: +52 55 5203 6887

Europe: +49 2158 95 1000 • Australia: +61 2 9890 5433

The following areas of this vender contain voltage which can

cause serious injury or even death: the main power cord,

supplying 115-230 VAC to the evaporator, EMI filter,

refrigeration system, monitor, and computer; the power line

from the EMI filter to the ballast and transformer; and the

ballast, which can produce upwards of 600 volts. Remove all

power from the vender before working in any of these areas.

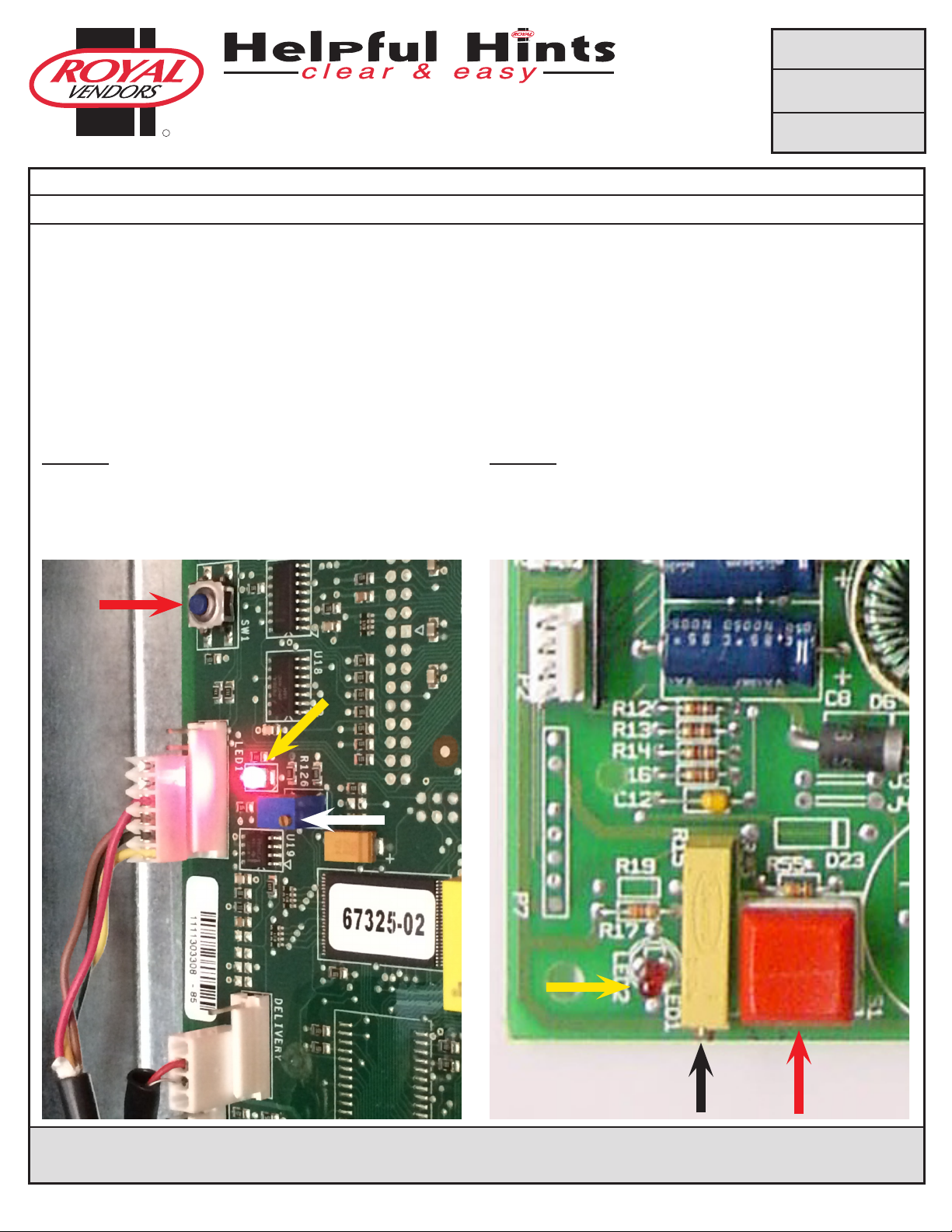

KO Controller (blue mode button):

Located near the control board’s chute sensor connector at position R126 is the sensor adjustment trimpot, which includes an

adjustment screw. (See Figure 1, on page 2.) The trimpot is used to adjust and fine tune the sensor. Located adjacent to the trimpot is

the sensor adjustment LED indicator light, at position LED1. The indicator light is mainly used to aid in adjusting the sensor, but can also

be used to test its operation during product impact.

FACTORY SETTING

Piezo sensor (at, newer-style sensor)

1. Turn the adjustment screw clockwise until the indicator light comes on.

2. Turn the screw counterclockwise until the light just goes out completely.

3. Continue to turn the screw counterclockwise 3/4 of a turn (one full turn is 360°).

4. Test vend columns 7 and 12 for proper function.

Impact sensor (hat-shaped, older-style sensor)

1. Turn the adjustment screw clockwise until the indicator light comes on.

2. Turn the screw counterclockwise until the light just goes out completely.

3. Continue to turn the screw counterclockwise 1 1/2 turns (one full turn is 360°).

4. Test vend columns 7 and 12 for proper function.

GII VII / EVS Controller (red mode button):

Located next to the control board’s mode button at position R15 is the sensor adjustment trimpot, which includes an adjustment

screw. (See Figure 2, on page 2.) The trimpot is used to adjust and fine tune the sensor. Located adjacent to the trimpot is the sensor

adjustment LED indicator light, at position LED1. The indicator light is mainly used to aid in adjusting the sensor, but can also be used to

test its operation during product impact.

FACTORY SETTING

Piezo sensor (at, newer-style sensor)

1. Turn the adjustment screw clockwise until the indicator light comes on.

2. Turn the screw counterclockwise until the light just goes out completely.

3. Continue to turn the screw counterclockwise 3/4 of a turn (one full turn is 360°).

4. Test vend columns 7 and 12 for proper function.

Impact sensor (hat-shaped, older-style sensor)

1. Turn the adjustment screw clockwise until the indicator light comes on.

2. Turn the screw counterclockwise until the light just goes out completely.

3. Continue to turn the screw counterclockwise 2 turns (one full turn is 360°).

4. Test vend columns 7 and 12 for proper function.