7. TROUBLESHOOTING

(A) PROBLEM: Unit will not start when the air valve is open and

the blue button has been pressed.

(A1) Cause: The operation of the button will normally be

and solution: accompanied by an audible ‘click’. If this sound is

not heard and there is no liquid in the reservoir turn

the unit upside down and try again. Otherwise incline

the unit to 45° and shake it several times then try

again.

(A2) Cause: The unit may require internal lubrication. Disconnect

and solution: the quick coupling. Open the air valve. Introduce a

few drops of air tool oil into the male coupling and

close the air valve. Reconnect the quick coupling.

When the unit is next operated the oil will be

distributed internally.

(B) PROBLEM: Automatic shut off does not operate when the

tank is full.

(B1) Cause: Turn air off manually and empty tank.

and solution: Take action as described in A1 and A2.

(C) PROBLEM: Extractor is working but no fluid is being

extracted.

(C1) Cause: All fluid has been extracted but tank is not full.

and solution: Turn off air manually.

(C2) Cause: Extractor probe is not fully immersed in the fluid.

and solution: Push extractor probe further into liquid/engine sump.

(C3) Cause: Tank is full.

and solution: Empty tank.

Dispose of waste liquids in accordance with local authority

regulations.

Always read and comply with the warnings on the brake fluid

container.

Wear eye protection and keep skin contact to a minimum. If brake

fluid enters eyes rinse with plenty of water and seek medical

advice. If swallowed seek medical advice immediately.

WARNING!Brake fluid is flammable - keep away from sources of

ignition, including hot surfaces e.g. exhaust manifold.

WARNING!Brake fluid will damage paintwork. Any spillage should

be flushed with water immediately.

8. BRAKE BLEEDING SAFETY

9. BRAKE BLEEDING OPERATION

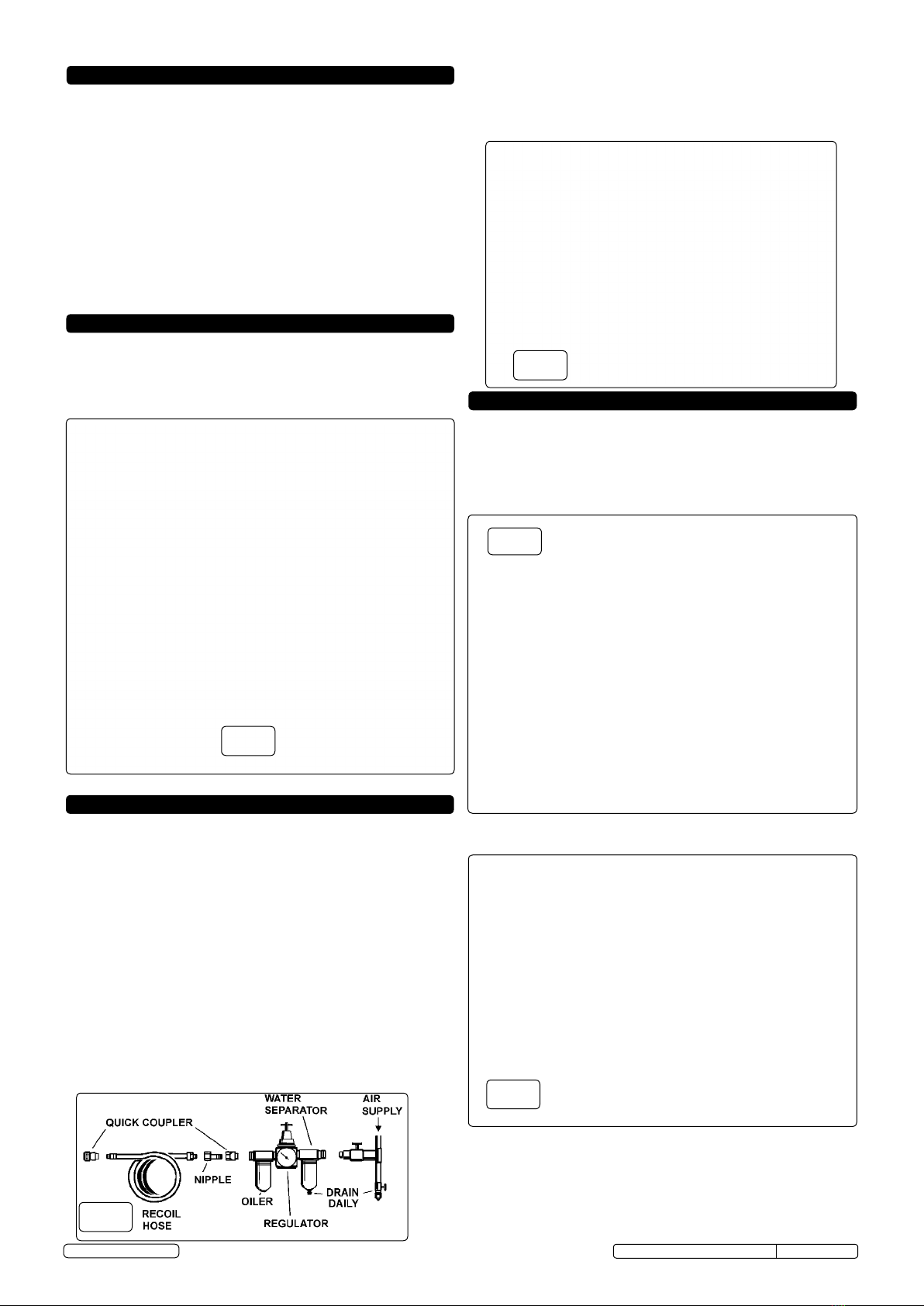

fig.12 fig.13

fig.11

BRAKE BLEEDING PROCEDURE. Do not touch the

vehicle’s brake pedal whilst bleeding the brakes.

Refer to the vehicle manufacturer’s instructions for brake

bleeding and wheel sequence before proceeding. If no specific

instructions from the vehicle manufacturer exist, follow the

instructions detailed below.

WARNING! Familiarise yourself with the hazards of brake

fluid - read manufacturer’s instructions on the container.

9.1. Remove the lid of the vehicle’s brake fluid reservoir. Fill the

reservoir to its maximum mark.

9.2. Identify the brake bleeding tube which has a blue flexible

plastic brake nipple connector at one end and a black rubber

adaptor at the other.

9.3. Connect the brake bleeding tube to the top of the fluid

extractor’s tank by pushing the black rubber adaptor into the

fluid inlet coupling.

9.4. Push the blue flexible plastic brake nipple connector onto the

brake nipple on the first wheel and open the nipple about 1/4

of a turn. (See fig.11)

9.5. Turn on the air valve on the extractor (TP6903.V2 &

TP6904.V2). Press the blue button to activate air operated

units or operate the pump handle on manual models. A

vacuum will be created which will draw the brake fluid from

the vehicle’s brake system. Operate the unit for a few seconds

only to avoid draining the vehicle’s brake fluid reservoir entirely.

9.6. IMPORTANT: Check the level of brake fluid in the vehicle’s

reservoir and top up regularly. If possible a reservoir top

up device should be fitted to the brake fluid reservoir.

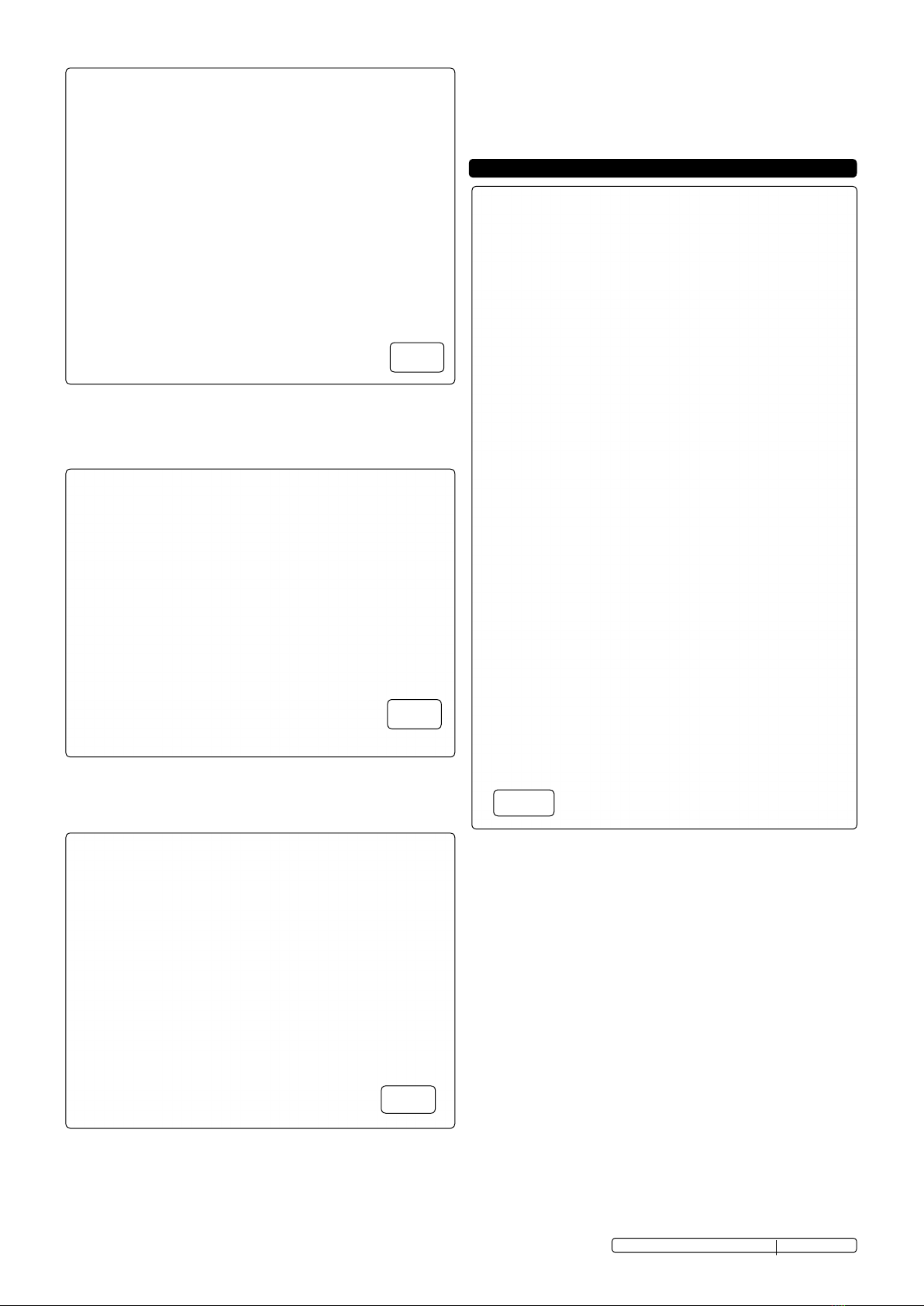

9.7. Continue to bleed the system and top up the reservoir until

there are no air bubbles visible in the clear tube (See fig.12).

9.8. Close the brake nipple (See fig.11).

9.9. Remove the rubber pipe from the brake nipple.

9.10. Repeat the process at each wheel in turn.

9.11. Changing the brake fluid

9.11.1. Repeat the brake bleeding procedure as described above

until the master cylinder reservoir is at its minimum level. Fill

the reservoir with new brake fluid and continue to bleed the

system. Check reservoir level regularly.

9.11.2. When new fluid can be seen in the clear tube tighten the

brake nipple.

9.11.3. Repeat this procedure at every wheel.

When brake bleeding and/or fluid changing is complete,

test action of brake pedal to ensure that the brakes are

working before driving the vehicle.

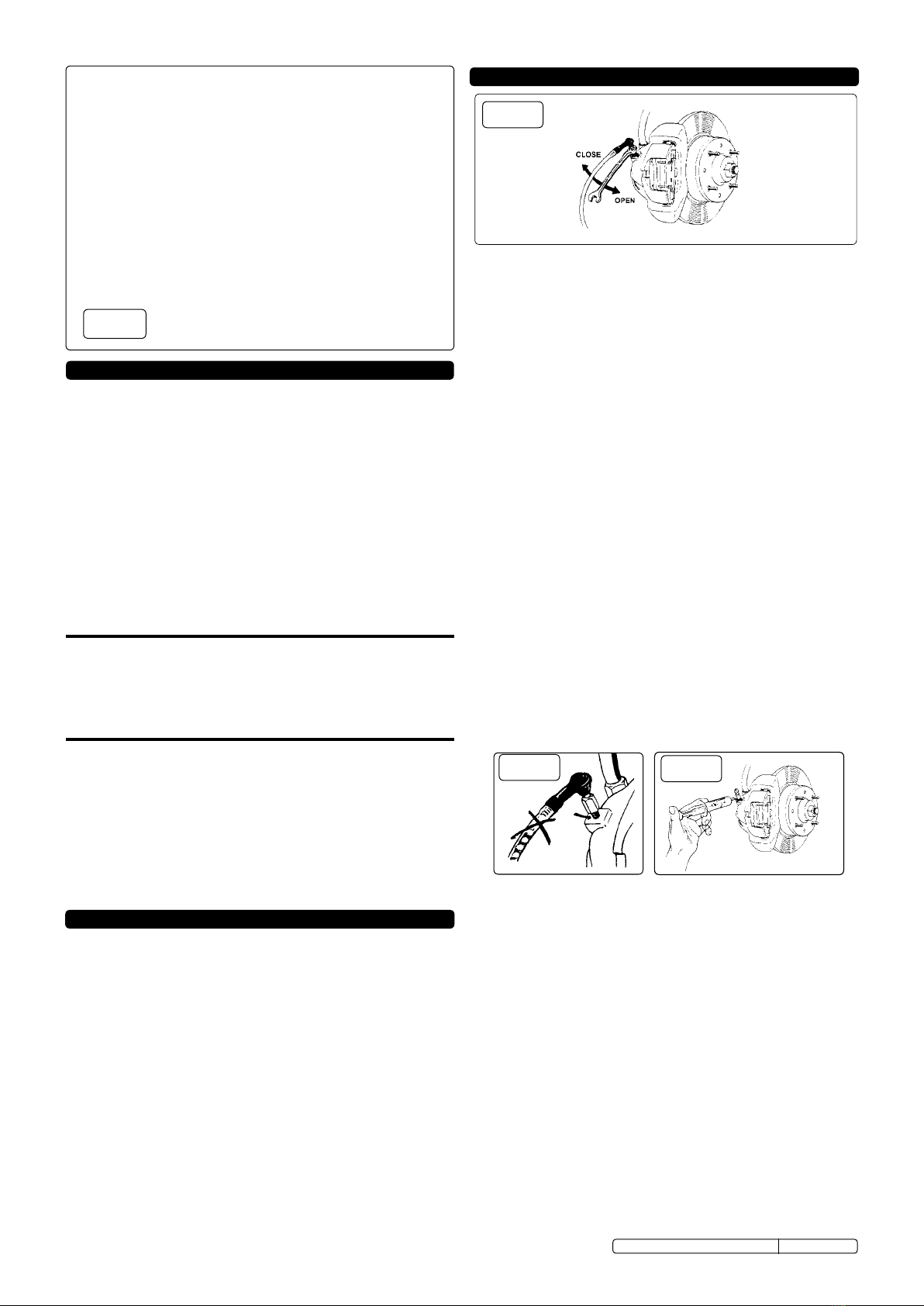

9.11.4. Apply copper grease to the brake bleed nipples before and

after the brake bleeding procedure to eliminate the possibility

of seized or broken nipples when the brakes are next bled

(See fig.13).

fig. 10

NOTE: It is our policy to improve products continually and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

TP6901.V2, TP6903.V2, TP6904.V2 Issue: 1-28/01/13