2

Section 1

Section 1Section 1

Section 1

Product Description

The MiniGala y E CO

2

Incubator is designed to ensure accurate and reliable operation. The unit

incorporates a touch sensitive keypad and two, 3 digit L. E. D. displays which allows easy setting and

onitoring of the cha ber condition.

The icroprocessor control syste ensures a rapid, controlled return to opti u cha ber conditions

after a door opening whilst also preventing any overshoot.

A ther al heating ele ent co pletely surrounds the incubator providing an even te perature within

the cha ber. The independently heated outer door is designed to ensure an even distribution of heat

thereby eli inating condensation on the inner door.

Incorporated into the unit is an over te perature safety syste . This operates independently of the

ain control syste .

A purpose designed hu idity control syste allows a high unifor relative hu idity and prevents

undesirable condensation in other parts of the cha ber. The anual control syste allows li ited

adjust ent over an approxi ate range of 95 – 97% r/h.

A solid state infra red sensor is used to control the level of CO

2

giving excellent reliability and is

unaffected by hu idity. The CO

2

syste has a se i-auto atic zero function which provides a si ple

process for the user to follow to aintain the correct CO

2

level within the cha ber.

There is a two level alar syste . The cha ber onitoring alar is progra able and will alert you

if te perature or CO

2

have not recovered within a preset ti e after the door has been opened. If not

required, this syste can be disar ed. Syste alar s occur only if a fault has developed which

requires user intervention to rectify.

Air circulation is achieved without the use of a fan eli inating this potential source of conta ination

and reducing s all sa ple evaporation within the cha ber.

The 50 litre cha ber and all internal co ponents are anufactured fro polished stainless steel.

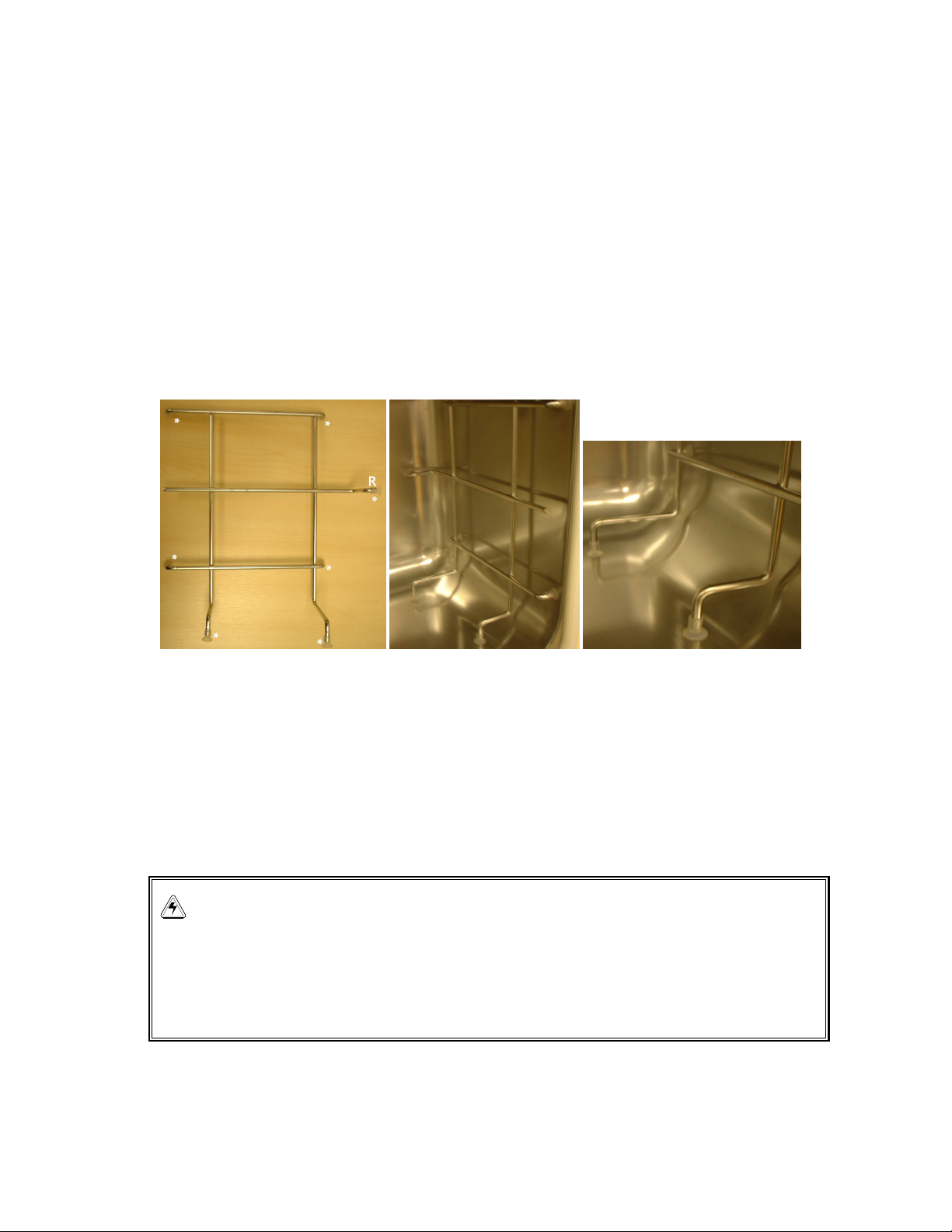

The shelf rack syste is designed for co plete re oval and easy access to the s ooth interior for

quick and thorough cleaning.

The outer shell of the incubator is anufactured fro zinc plated stove ena elled steel to give a

durable corrosion resistant finish.

The outer door and top cover are vacuu for ed fro ABS plastic and they provide a high level of

insulation. The keypad and display are incorporated into the top cover per itting axi u usable

cha ber volu e.