28. Wear protective work wear appropriate for the job and for the job and work

environment. In addition to the suitable work clothing, additionally include

safety shoes, hard hat, hearing protection, non-fogging vented safety

goggles, and proper respiratory protection mask to prevent dust inhalation.

Personal safety must always be observed when operating the RUBICON 480.

29. The RUBICON 480 must only be used in accordance with the instructions

given in this manual. Any other work methods or practices are not approved

and could result in serious injury or death.

30. WARNING: Disconnect the power before moving the handle to the

TOOLING or LIFT/STORAGE position.

31. WARNING: POISONOUS EXHAUST GASES. Do not operate petrol powered

equipment, including generators, without adequate ventilation. Carbon

monoxide is an invisible, odourless gas that can harm or can kill.

32. Be sure all equipment is tested and tagged prior to use on any job.

33. Bolts, concrete nails, or other embedded metal objects could damage the

tooling or the machine and potentially cause a hazardous situation. Be sure

before starting any job.

34. Ensure there are no obstacles or existing structures that could present a

hazard to the operator. Take necessary action to eliminate the hazard or

mitigate the risk of personal or property damage.

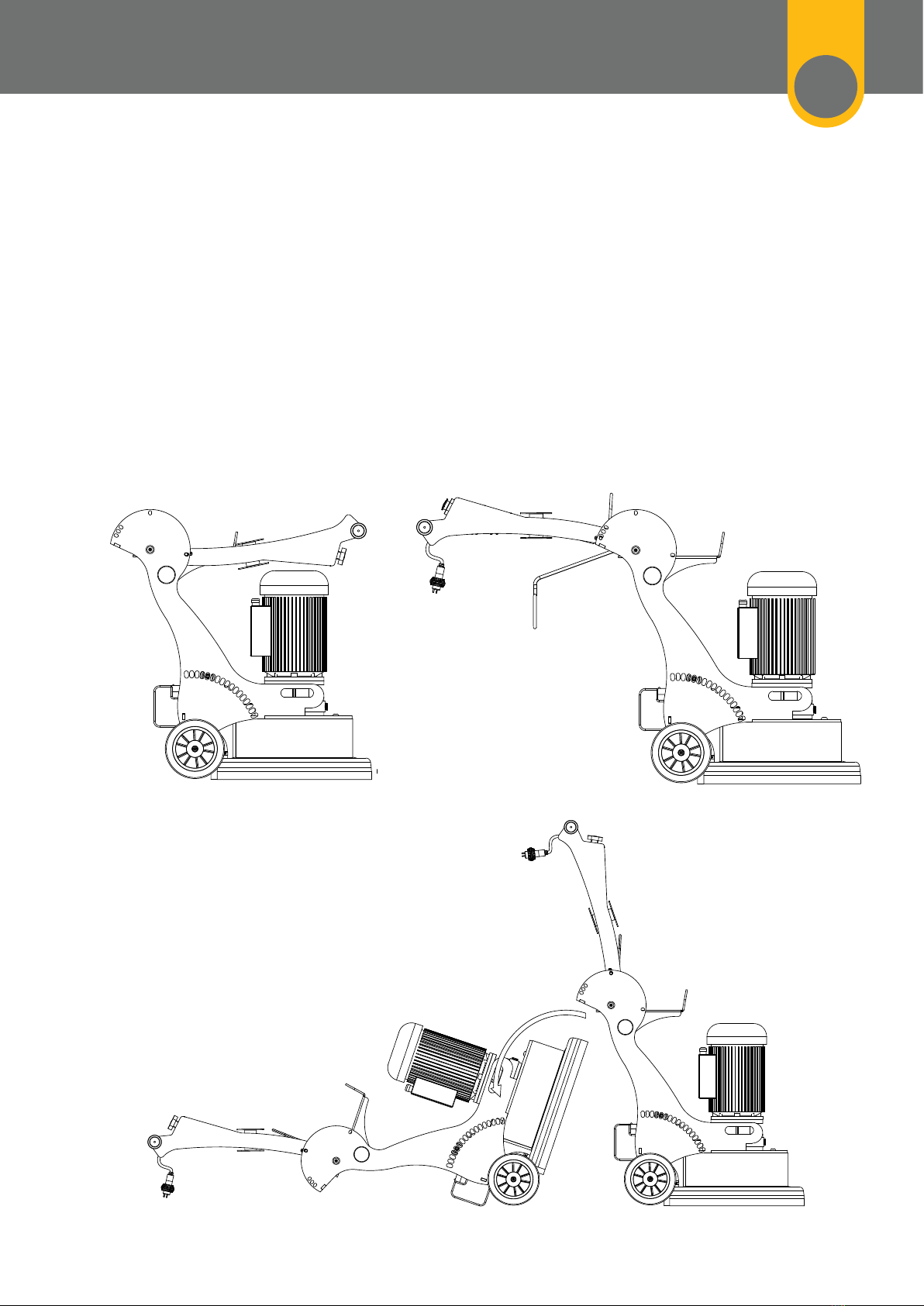

35. When storing the machine after use, fold the handle to the TOOLING

position only after all moving parts have stopped, the cord has been

removed from the power supply and the spark plugs have been removed.

Ensure the machine is locked in place in the TOOLING position, then tilt it

36. The machine takes a set of three diamond tools. Be sure the tools installed

are of even height.

37. Install the tooling with the machine in the TOOLING position. See the

Tooling Position & Magnetic Plugs section for illustrations on how to

correctly install and remove the tooling. Only use genuine retailer’s genuine

diamond tooling with the machine. Failure to comply could result in bodily

injury or damage to the machine or property.

38. Once the tooling is installed, tilt the machine back upright and put the

handle in one of the three OPERATE positions. Adjust to the position that

feels most comfortable for the operator.

39. Never attempt to adjust the handle position while machine is operating.

Operating Instructions

6