1

ATEX Pumps - Conditions For Safe Use

1.Ambient temperature range is as specified in page 16.

2.ATEX compliant pumps are suitable for use in explosive atmospheres when the equipment is

properly grounded in accordance with local electrical codes

3.

Conductive Polypropylene, conductive Acetal or conductive PVDF pumps are not to be installed

in applications where the pumps may be subjected to oil, greases and hydraulic liquids.

4.

Ruby 010 3/8’’ shall not be installed in applications and areas with hydrogen and acetylene

atmosphere.

5.

When operating pumps equipped with non-conductive diaphragms that exceed the maximum

permissible projected area, as defined in EN ISO 80079-36 : 2016 section 6.7.5 table 8, the following

protection methods must be applied:

-Equipment is always used to transfer electrically conductive fluids or

-Explosive environment is prevented from entering the internal portions of the pump, i.e. dry

running.

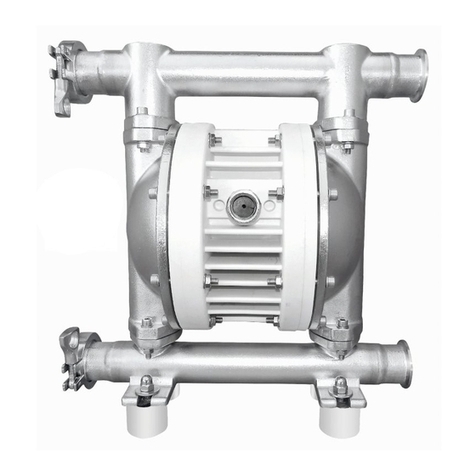

1.0 Introduction

Ruby pumps have been manufactured to the 2006/42/EC, 2014/34/EU directives. The relevant

area criteria are indicated in the EN-60079-0:2018 , EN-12100:2010 , EN-809:1998+A1:2009 , EN-

80079-36:2016, EN-80079-37:2016, EN-80079-38:2016 harmonized European standards.

Therefore, if used according to the instructions contained in this manual, the Ruby pumps will not

represent any risk to the operator. This manual must be preserved in good condition and/or

accompany the machine as reference for maintenance purposes. The manufacturer rejects any

liability for any alteration ,modification, incorrect application or operation not complying with the

content of this manual and that may cause damage to the health and safety of persons, animals or

objects stationing near the pumps. The following instructions solely refer to Ruby Air Operated

Diaphragm Pumps. Since the pumps are used in combination with other assemblies, such as

solenoid valves, sensors or pulsation dampers, the valid operating instructions for these

components and the associated notes on safety must also be taken into account. These

instructions contain information on safety, installation, operation, maintenance, repair and

environmental waste disposal of the Ruby Air Operated Diaphragm Pump. Thoroughly read these

instructions before use and always follow the information contained therein. Persons entrusted

with the installation, operation, maintenance or repair of the pump must have read and

understood these instructions, especially the chapter on “Health and Safety”. This applies in