6

4

4.

.I

IN

NS

ST

TA

AL

LL

LA

AZ

ZI

IO

ON

NE

EI

IN

NS

ST

TA

AL

LL

LI

IN

NG

GT

TH

HE

EP

PE

EL

LL

LE

ET

TS

ST

TO

OV

VE

E

General instructions

For levelling of the stove the machine mounts under

the device can be adjusted in height and locked

(counter nut SW13).

The function of the smoke venting system is based on

negative pressure in the combustion chamber and a

minor superpressure on the flue gas outlet. Therefore

correct and airtight installation of the flue gas

connection must be ensured.

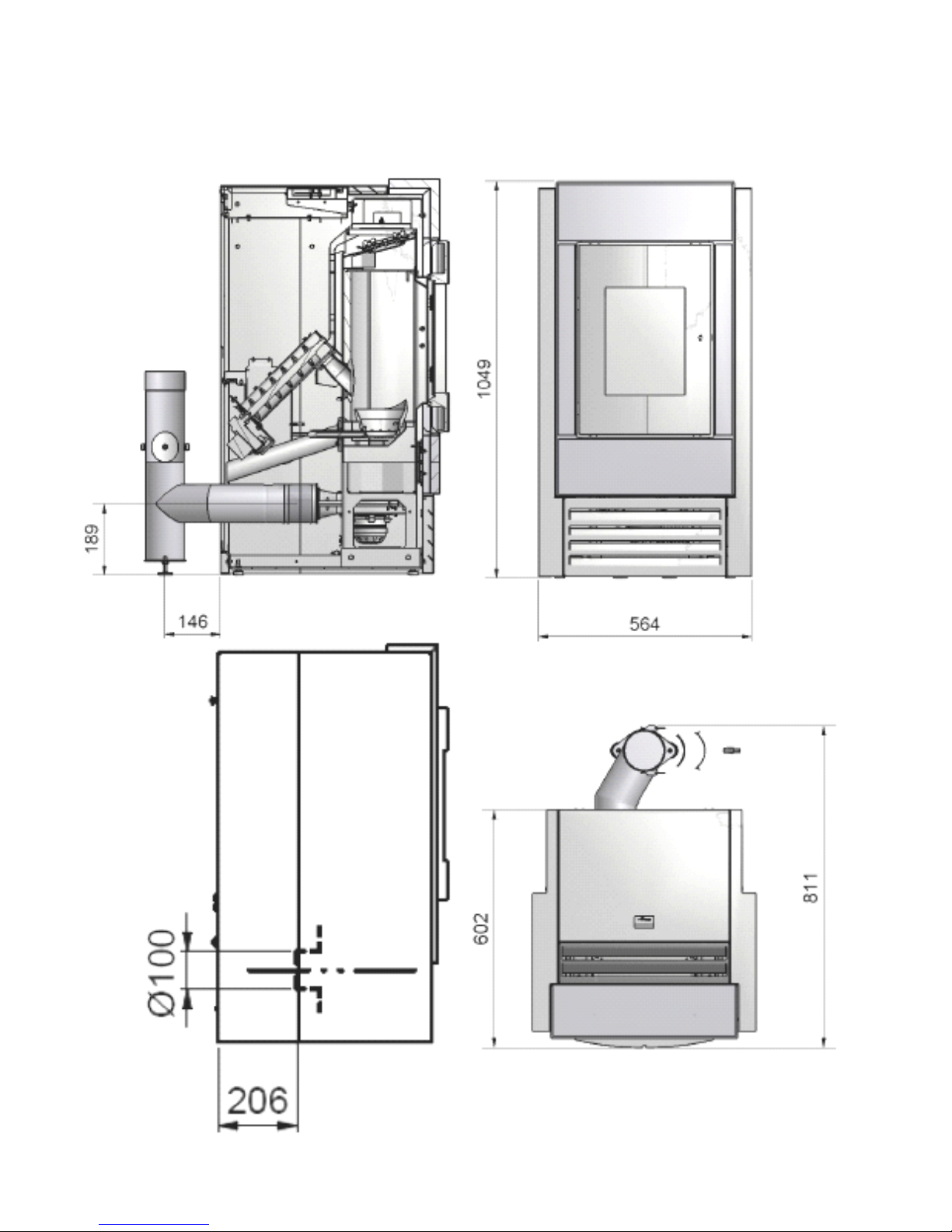

The device must be connected to a chimney approved

for solid fuels. The diameter of the chimney must be

at least 120mm. In case of a chimney with a diameter

exceeding 200mm and a certain height installation of

a draft reduction may be required. This is why you

should consult a chimney expert prior to installation of

the stove. In cooperation with the stove fitter who may

adjust the parameters of the control, the chimney

expert can ensure the proper connection of the stove

to the chimney.

IMPORTANT!

Only use heat resistant sealing materials and

applicable sealing bands, heat resistant silicone and

mineral wool.

We recommend to charge an authorized expert with

the assembly (and/or control and acceptance for self

installation)!

Also ensure that the flue tube does no extend into the

free cross section of the chimney.

CAUTION!

xPlease observe the applicable regional building

regulations. Ask your chimney sweep for advice.

xFlue pipes should not be too long.

xAvoid too many changes of direction for the flue

gas flow to the chimney. (e.g. too many corners

and bends)

In case of self installation the installation must be

accepted by a partner certified by Rüegg in order for

the warranty to be valid. The costs for the initial

commissioning with customer introduction and setting

of the parameters by the charged service partner are

in most cases charged separately. Ask your service

partner for a service subscription.

Electric connection

The stove is supplied with an approximately 2.5m long

connection cable with a Euro plug. Connect the cable

to a 220/230V, 50Hz power connection. For

installations in Switzerland replace the Euro plug by

the supplied plug. The average electric power

consumption during operation is approximately 100W.

During the automatic ignition process (duration

approximately 10 minutes) approximately 350W. The

connection cable must be laid in a way that any

contact with hot or sharp-edged external surfaces of

the stove is avoided.

Combustion air

Every combustion procedure requires oxygen and/or

air. For individual stoves this combustion air is

generally taken from the living area. The air taken

from the living area must be reintroduced. In modern

houses with very tight fitting windows and doors the

amount of air flowing back may not be enough. This

situation may also become problematic due to

additional ventilation in the house (e.g. in the kitchen

or toilet).

External air supply

This external air supply means, that this air is supplied

to the stoves adaption connector by means of a tube

or duct, directly from outside or from another room

(e.g. cellar or boiler room) This connector does not

lead directly into the combustion chamber, but to the

inside of the pellet stove. This has the advantage that

the stove can take exactly the amount of air it needs,

and that this air is already preheated by passing

through the room. If the stove is not used, there

should be a possibility to close this air supply as close

to the facade as possible, to prevent cold damp air to

flow into the duct and unnecessarily cool down the

room or at temperatures well underneath 0° C to

provoke condensation problems. Therefore it is

important to insulate the ducts and make sure that

eventual condensation fluid can run off freely in the

right direction.