-10-

12-94

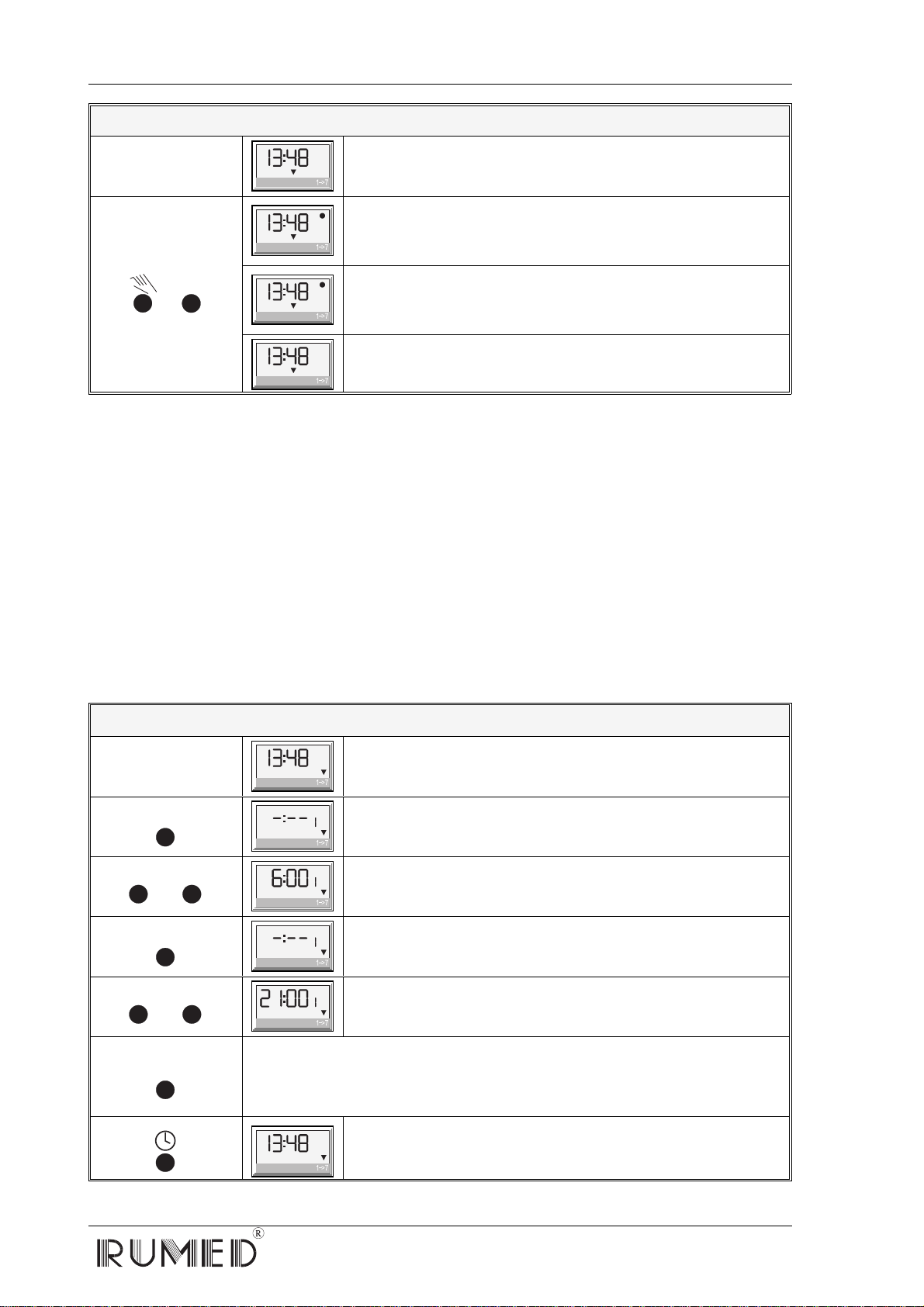

Change of the Switching Status

OFFOF

1234567

Clock indicates the actual time

(f. ex. 13.48 h) Switching status is "Automatic OFF"

+

m

ON

1234567

Press and hold key m and press key Hand once. The switching

status will change-over to "PERMANENT ON"

(display indicates a point above ON)

OFFOF

1234567

Press and hold key m and press key Hand once. The switching

status will change-over to "PERMANENT OFF"

(display indicates a point above OFF)

OFFOF

1234567

Press and hold key m and press key Hand once. The switching

status will again change-over to "AUTOMATIC" (point disappears)

Daily Programme

When the mode "daily programme" is activated, maximum 6 ON- and 6 OFF-commands can be

programmed. However, for one programme cycle only 1 ON- and 1 OFF-command is required. The

command ON starts the programme, the command OFF terminates the programme. At the same time,

a programme reset is effected in the temperature controller, which is the only possibility for a further

programme start.

Correspondingly, the time delay between an OFF-command and the next ON-command must be at

least 1 minute, otherwise the programme reset cannot be effected and the programme controller will

not change to the next programme cycle (i. e. in the operating mode "daily programme" it is possible to

run a four-hour programme cycle six times per day maximum).

The following table shows the programming of the response times for our dual setpoint programme

example.

Programming On- and Off-Commands (Operating Mode "Daily Programme")

OFFOF

1234567

Clock indicates the actual time

(f. ex. 13.48 h)

Prog.

ON

1234567

Press once, to call the programming mode

(Here: f. ex. not yet programmed)

or

h

m

ON

1234567

Enter time for the command 1 ON by means of the keys h

and m(Here: f. ex. 6.00 h)

Prog.

OFFOF

1234567

Press once, to call the command 1-OFF

(Here: f. ex. not yet programmed)

or

h

m

OFFOF

1234567

Enter time for the command 1 OFF by means of the keys h

and m(Here: f. ex. 21.00 h)

Prog.

There are no further switching commands required for our example

programme! If requested, all other switching commands can be called

successively on pressing the key Prog.

(2 OFF, 3 ON, 3 OFF, 4 ON, 4 OFF, 5 ON, 5 OFF, 6 ON, 6 OFF ☛after 6 OFF, 1 ON 1 OFF etc. will be repeated)

OFFOF

1234567

Press once, to terminate the programming mode and to

return to the normal display (If there will be no entry within 30 sec., the

display will automatically return to actual time).