2009-03

7

RVR

Energy Technology Experts

Star NE

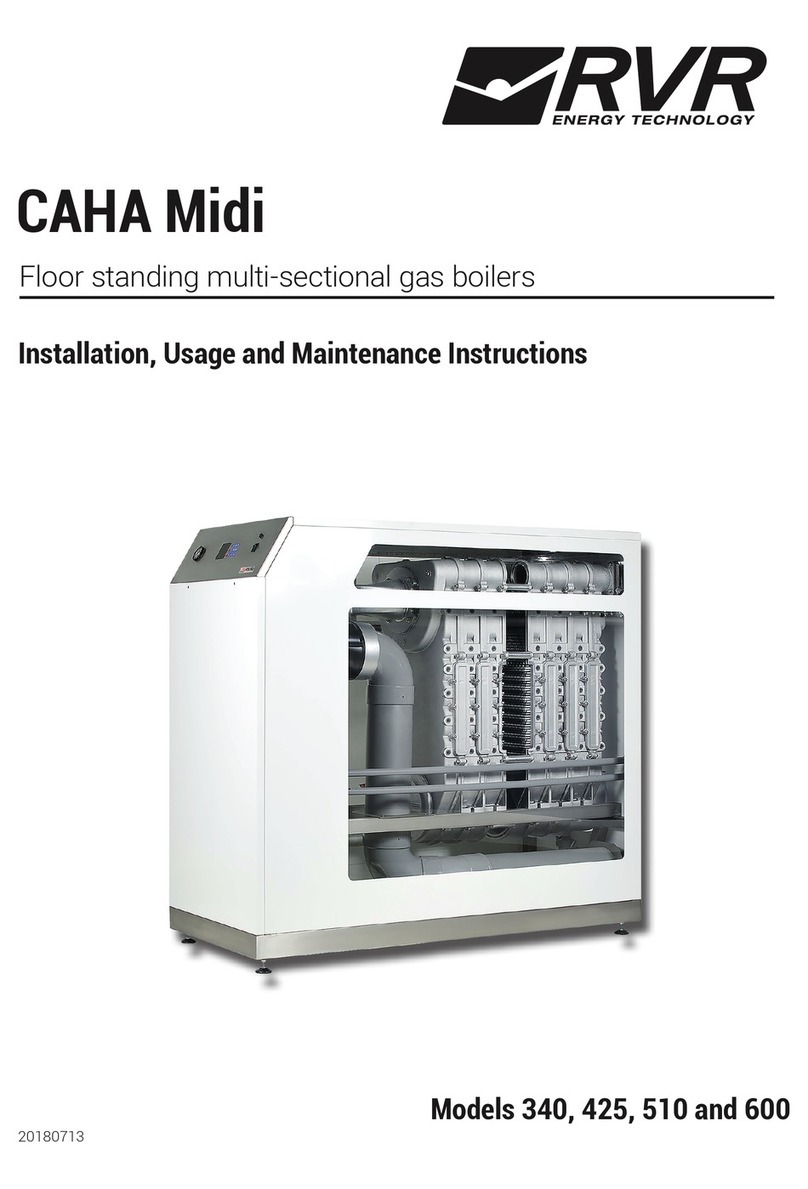

Control panel

After installation, check with the installer that the system is in perfect

condition. Ask the installer to demonstrate the settings and functions so

you know how to operate and care for the system.

The pressure varies with the temperature, do not add water unnecessarily.

For filling, the shunt must be fully open, position 10.

Always disconnect the power supply to the boiler before:

opening the burner hatch

draining the boiler water

accessing the automation cabinet or units powered by the boiler.

Commissioning and checks

Before putting the system into operation, check that:

- the system is filled with water.

- all connections are watertight.

- flue gas connections to the boiler and to the flue are tight.

- the filling/drain valve has been closed properly.

- the safety valves are working properly.

- the necessary valves are open.

- the circulation pump is working and the direction of flow is correct.

Water pressure in the system

The pressure in the heating system depends on the distance

between the highest and lowest points in the system, the static

head. If the difference is 5 metres, the pressure is 0.5 bar, if it is

10 metres, the pressure is 1.0 bar.

The volume of water changes with the temperature, affecting

the pressure in the heating system. Higher temperatures

increase the volume and pressure. The expansion vessel takes

up the changes in volume in the system.

Bleeding/topping up

Regularly check that there is enough water in the heating

system. The pressure gauge should indicate 0.5- 1 bar. Air may

remain in the heating system for a while after installation, so

bleeding should be repeated a few times. After bleeding, check

the pressure and add water if necessary.

Dirt filter

There is a dirt filter in the cold water pipe leading to the heat

exchanger, preventing impurities getting into the water in the

heat exchanger. If the filter becomes clogged, the pressure of

the hot water will fall. You can clean the filter – after shutting off

the water – by removing the plug next to the filter.

Circulation pump

If the boiler is shut down for a long time, there is a risk that the

heating and hot water circulation pumps might seize up. You

can prevent this by running the pumps from time to time.

THERMOSTAT MAIN SWITCH

RESET

OVERHEAT

TEMPERATURE

PRESSURE

Star

NE

Safety valves

The safety valves in the system must be operated regularly,

around four times a year, in order to preserve the safety func-

tion.

Boiler temperature

The boiler temperature should not fall below 70 °C in pellet

operation.

Pellet operation

In burner operation, the draught must be ≤0.05 mbar.

The boiler temperature is controlled by the burner thermostat – for

the various options, see the energy source selector on page 8.

For optimum reliability and efficiency, it is essential to check

and adjust the burner regularly.

Overheating protection

The boiler overheating protection is triggered when the boiler

temperature exceeds around 95 oC. The protection can be

reset on the front panel once the boiler temperature has fallen

to around 80 oC.

If there is a risk of freezing

In severe cold weather, no part of the heating system should

be turned off as this would involve a risk of burst pipes. The

boiler must not be put into operation if any part of the heating

system is suspected of being frozen. Call the installer.

If the water boils

Disconnect the power supply to the boiler, then fully open the

nearest hot water tap.

Flue cleaning

Ash and soot are formed in pellet operation, so the boiler must

be regularly cleaned, if possible when the flue gas tempera-

ture has risen by around 50 °C compared to when the boiler is

clean.

The turbulators must be checked every time the boiler is

cleaned. Damaged turbulators should be replaced. With a cor-

rectly adjusted burner, flue cleaning will not be necessary be-

tween the regular visits of the flue sweep.

Boiler cleaning

Keep the boiler clean and tidy. Alkaline cleaning agents are use-

ful for removing soot marks from the boiler.

Operation and care

1. Thermostat. Setting of boiler temperature during

burner operation. Recommended setting min 70 °C.

23. Main switch, which breaks the control current to the

boiler, as well as units powered by the boiler.

52. Resetting, overheating protection. Resetting may take

place when the boiler temperature has fallen to approx.

80 °C.

71. Thermometer, shows the boiler temperature.

72. Pressure gauge, shows the water pressure in the heat-

ing system.

123

17

71

72