2

EasyStove Installation, Usage and Maintenance Instructions

CONTENTS

01. General Information........................................................................................................................................ 3

Warning ..................................................................................................................................................... 3

02. Operation.......................................................................................................................................................... 3

03. Technical Information..................................................................................................................................... 4

Principal Components............................................................................................................................ 4

Heat Exchanger Characteristics .......................................................................................................... 5

Flowrate Vs Pressure ............................................................................................................................. 5

04. Important Points.............................................................................................................................................. 6

Safety Warnings ...................................................................................................................................... 6

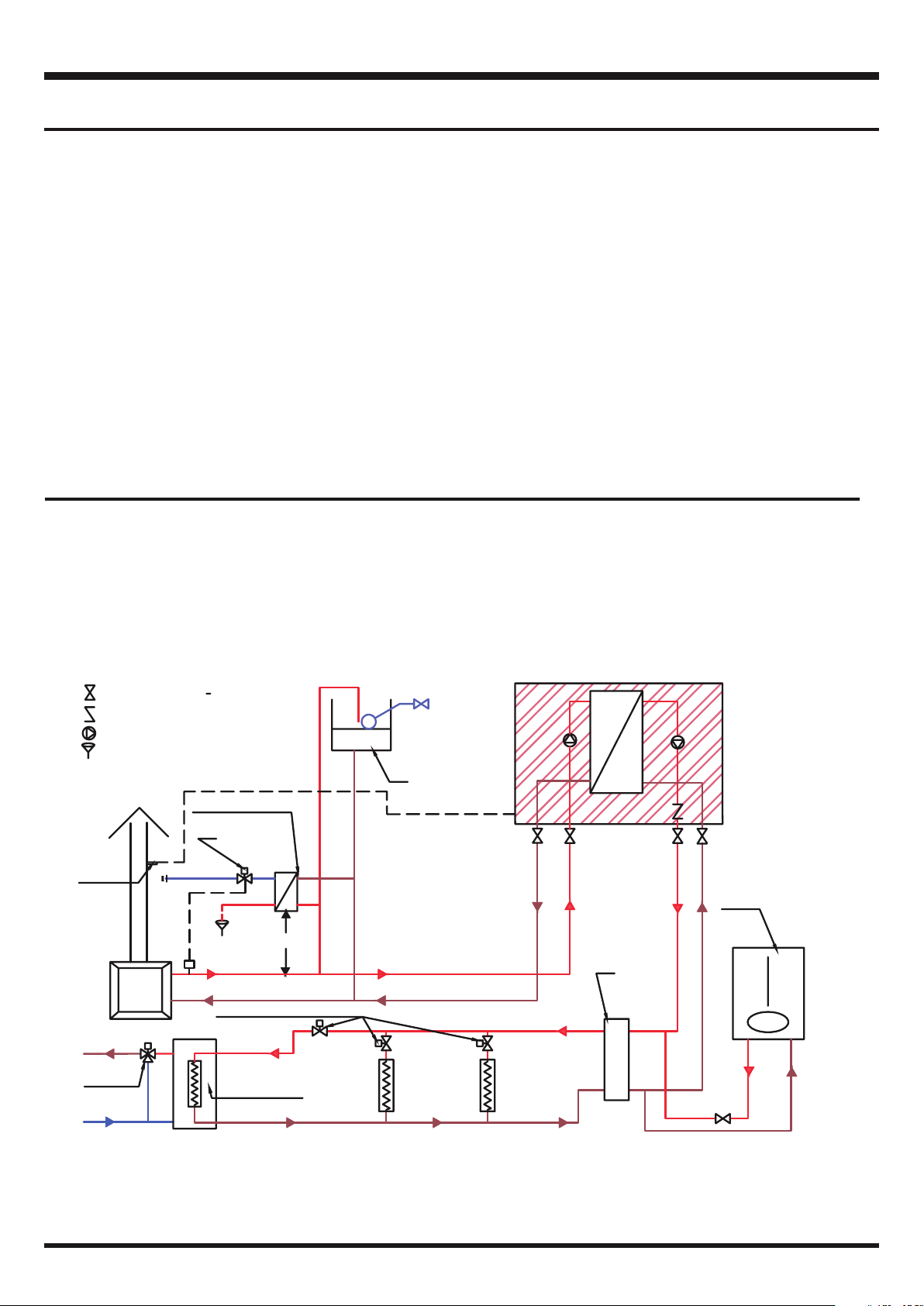

05. System layout .................................................................................................................................................. 7

Fundamental requirements .................................................................................................................. 7

Suggested System Layout ................................................................................................................... 7

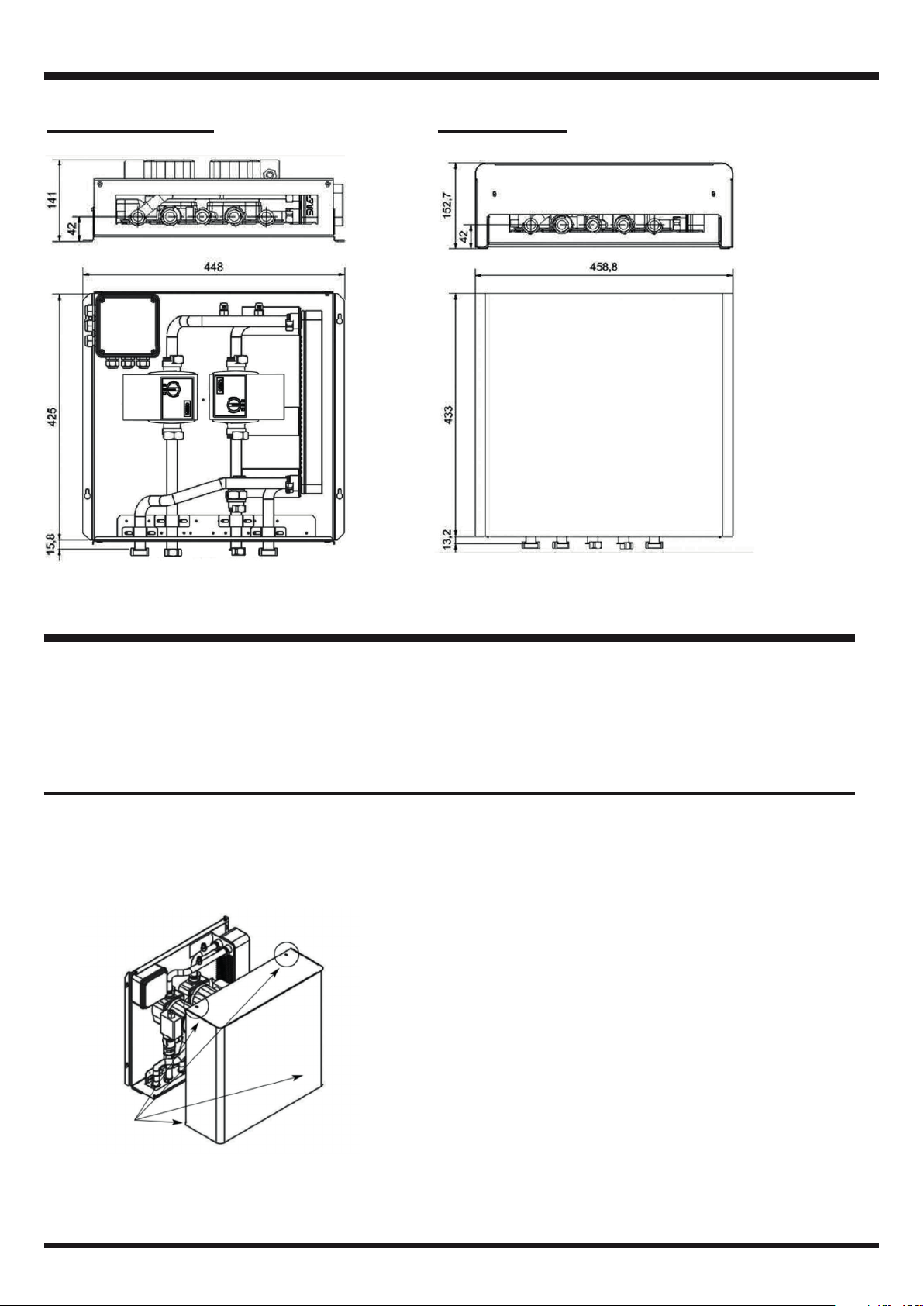

07. Dimensions....................................................................................................................................................... 8

Without Cover .......................................................................................................................................... 8

06. Installation ........................................................................................................................................................ 8

Wall Mounting .......................................................................................................................................... 8

With Cover ................................................................................................................................................ 8

Mounting of Flue Thermostat................................................................................................................ 9

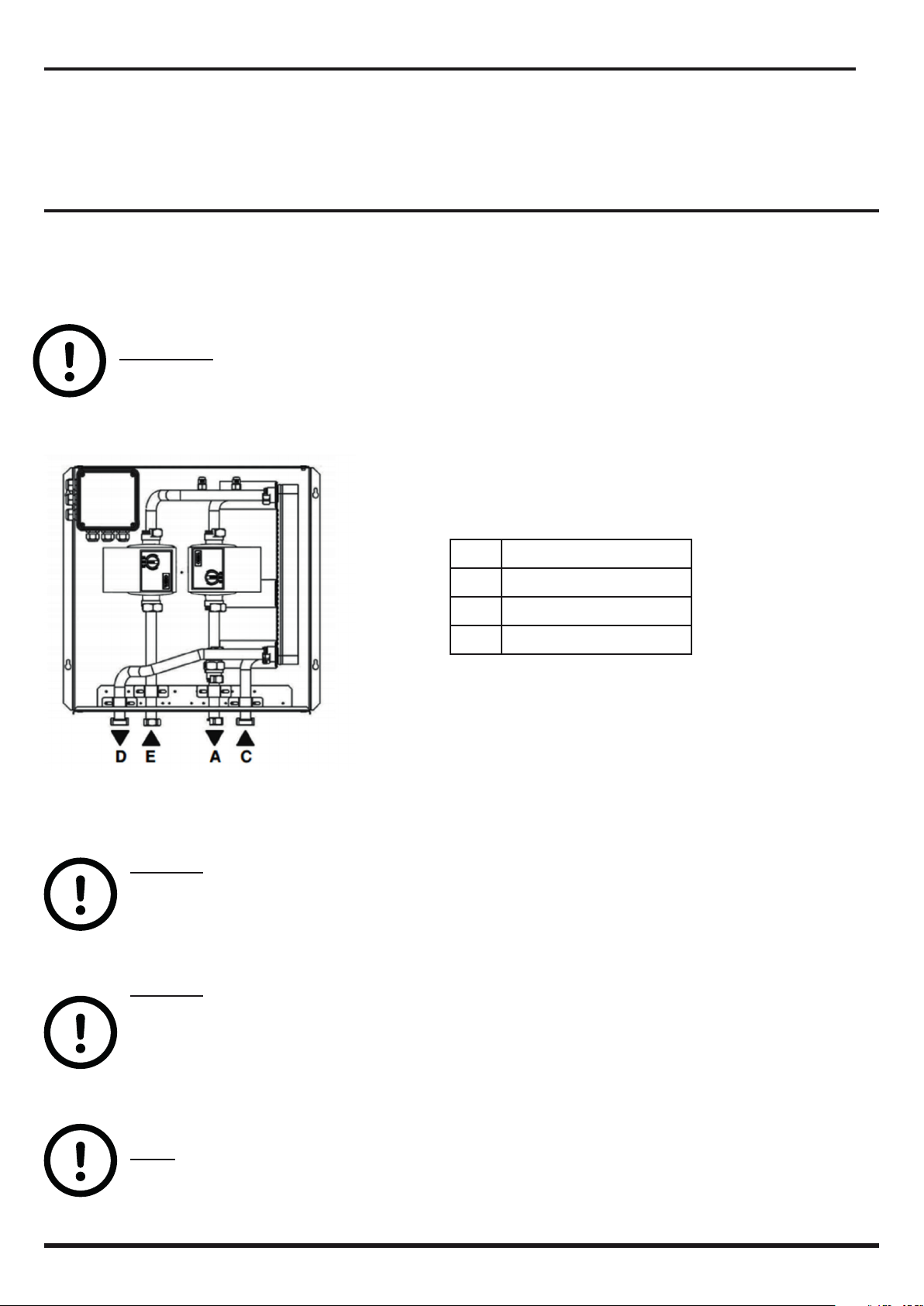

Hydraulic connection ............................................................................................................................. 9

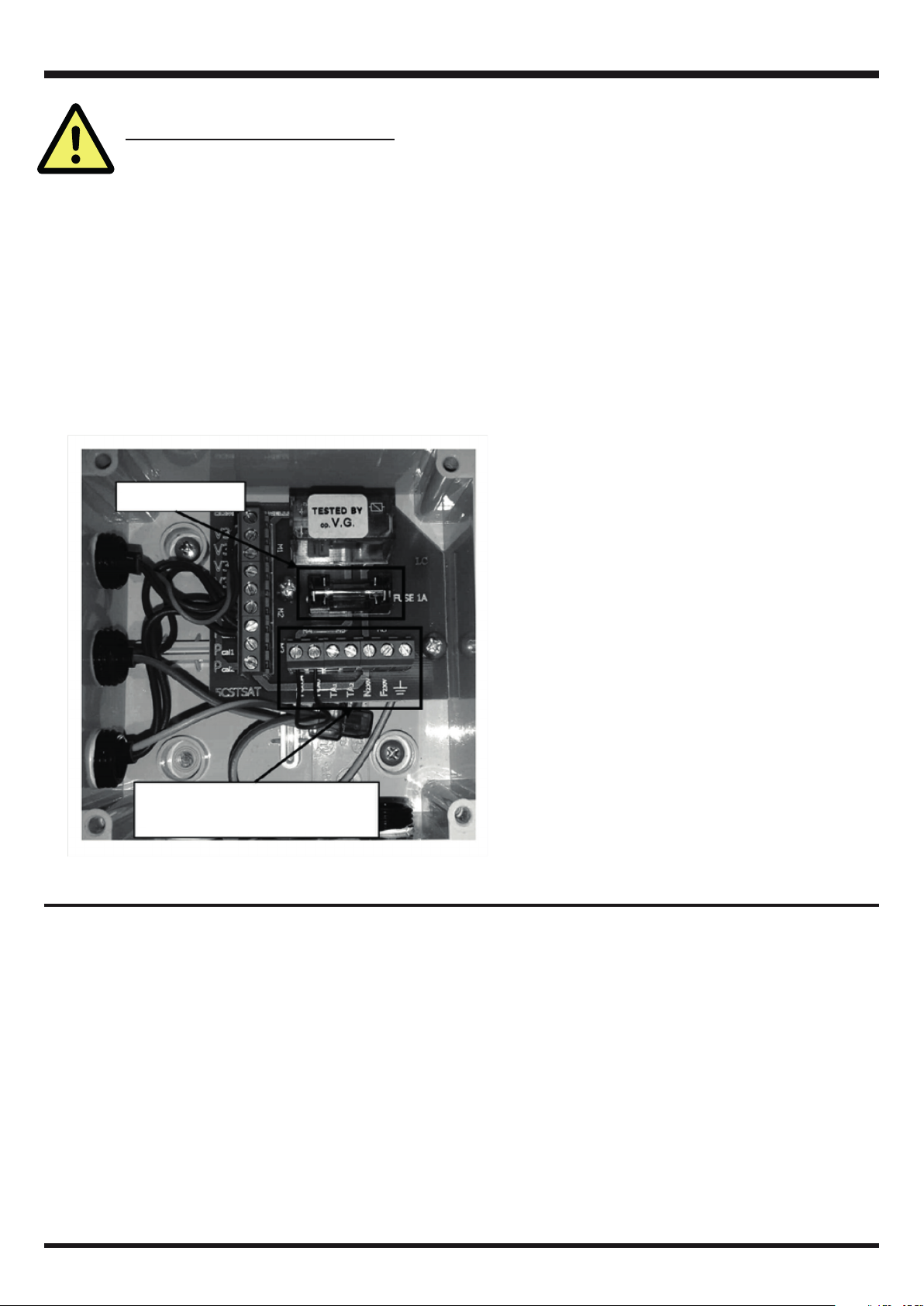

08. Electrical connection ...................................................................................................................................10

Power supply .........................................................................................................................................10

Connection to solid fuel boiler ...........................................................................................................11

Schematic...............................................................................................................................................11

09. Commissioning..............................................................................................................................................12

Circulation Control................................................................................................................................12

10. Maintenance and troubleshooting.............................................................................................................13

11. Spare Part List ..............................................................................................................................................13