3

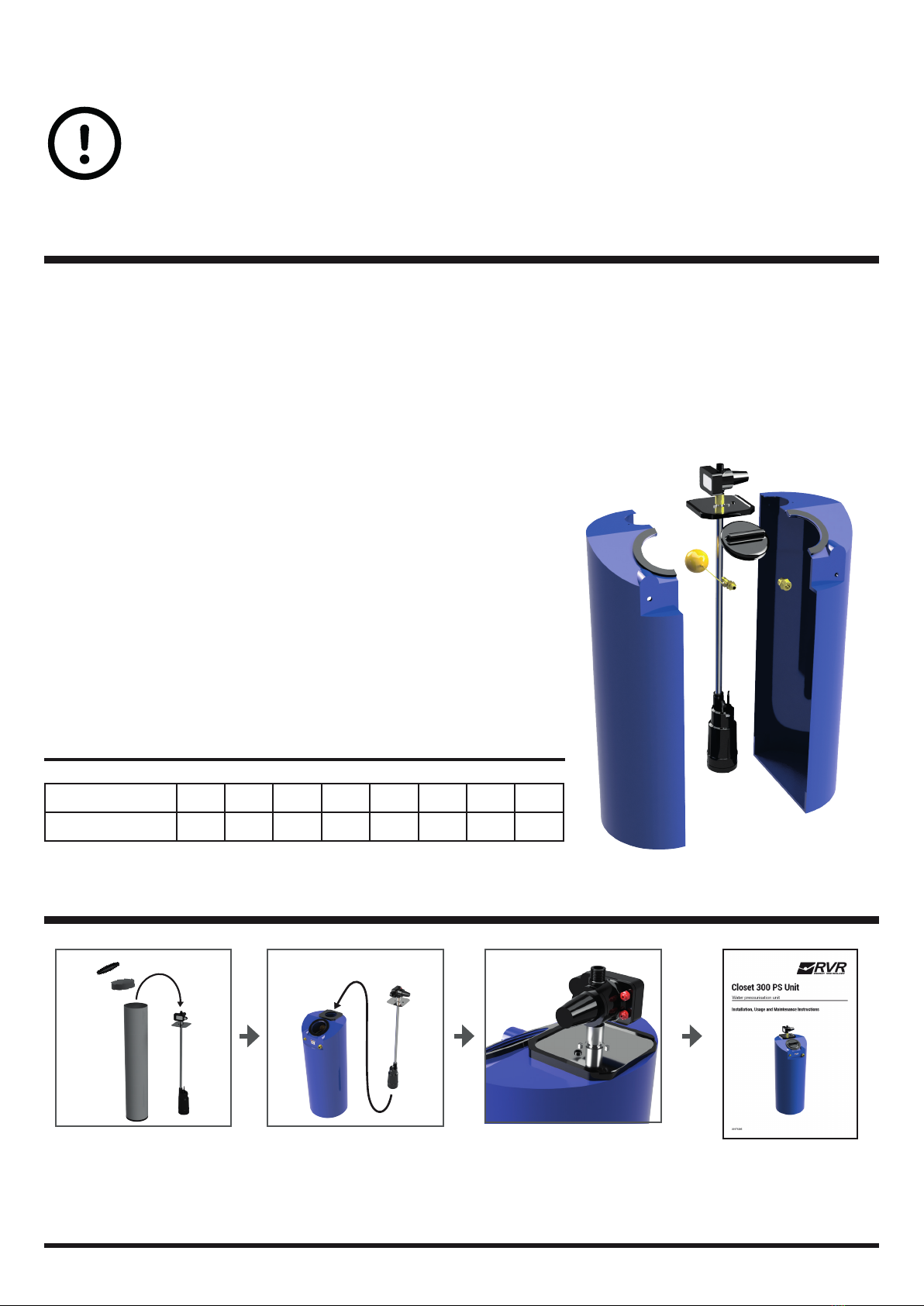

Closet 300 PS Unit Installation, Usage and Maintenance Instructions

The Closet 300 PS is supplied with a 3 core mains cable with a length of 2 metres. A 220/240V 50Hz single phase supply

with neutral and earth is required. All wiring must comply with l.E.E. and all local, national and EU requirements. THIS

APPLIANCE MUST BE EARTHED.

Pump Model Motor Power Rated Current Minimum Fuse Size

Diver 6-700 M-A 0.65kW 3.8A 6A

The method of connection to the electricity supply must facilitate complete isolation and should preferably be made via

a fused isolator having a contact separation of at least 3mm in all poles and supplying the pump circuit only. The fused

isolator should also protect the cable supplying the unit.

A fuse/MCB suitable for the protection of motor loads should

protect the circuit to which the pump is connected. The instal-

lation of a ground fault interrupter / RCCD-protector is strongly

recommended.

Cable extensions should only be made with a safe and water-

proof system. The system should be interconnected as shown

in the diagram (L: Brown N: Blue E: Green/Yellow ) using suitable

cable with a cross section of at least 1.5mm2.

Note - the pump connection (indicated in shaded area) comes

pre-connected on Closet 300 PS.

03. INSTALLATION AND CONDITIONS OF USE

This product must be installed subject to the following limitations:

▪Temperature of pumped liquid between 0ºC and +35ºC

▪Voltage variation allowed +/-5%

▪Maximum number of starts per hour : 40

▪Maximum water column between controller and highest water outlet: 6m

▪Minimum positive head level: 100mm

▪The pump is not suitable for pumping inflammable liquids or for use in locations where

there is a danger of explosion

▪The pump is not suitable for use in swimming pools or garden ponds

▪Do not cover or place anything on top of the controller

Install the Closet 300 PS unit in a dry location, indoors. Vibration isolating material

should be installed underneath the unit. The unit must be installed in a vertical

orientation, otherwise the pump will not operate correctly or leaks may occur.

Make sure that the water is free from sand, grit and other dirt. Do not run the

pump without water. The controller will stop pump operation when there is no

water and will need to be reset when this occurs.

The installer must pressure test the water system fully to ensure there are no leaks before connecting and starting the

pump for the rst time. The maximum pump pressure is 3.5 bar. The pressure test should be carried out at a pressure of

at least 5 bar. Failure to ensure the integrity of all pipework, joints and ttings may result in flooding and property damage.

RVR Energy Technology accepts no liability for damage due to leaks either inside or outside the product.

We recommend the installation of a small (5 litre) expansion vessel on the cold water outlet, which will result in reduced

pump operating cycles and also eliminate frequent starting due to drips and leaks. This will prevent premature failure due

to frequent cycling. If an expansion vessel is installed, the expansion vessel charge pressure should be set to 1.5 bar with

no water pressure in the system. The system will operate satisfactorily without an expansion vessel provided the number

of start/stop cycles does not exceed 40 per hour.

We recommend the installation of an isolation valve on the pressurised outlet. A suitable flexible hose or connector should

be used to connect the Closet 300 PS to the pipework.

COLD WATER

INLET

OVERFLOW

PRESSURISED

OUTLET

04. ELECTRICAL INSTALLATION