6

OPERATION

nGreen LED on = When battery pack is inserted into

charger, indicates hot battery pack or that battery pack

is out of normal temperature range.

nYellow and Green LEDs on = Deeply discharged or

defective battery pack.

nNo LED on = Defective charger or battery pack.

CHARGING THE BATTERY PACK

Battery packs for this tool are shipped in a low charge

condition to prevent possible problems. Therefore, you

should charge it until the green LED on the front of the

charger comes on.

NOTE: Batteries will not reach full charge the fi rst time they

are charged. Allow several cycles (operation followed by

recharging) for them to become fully charged.

CHARGING A COOL BATTERY PACK

If battery pack is within normal temperature range, the red

LED on charger will come on.

NOTE: If the charger does not charge the battery pack

under normal circumstances, return both the battery pack

and charger to your nearest Ryobi Authorised Service

Centre forelectrical check.

nCharge the battery pack only with a recommended

charger.

nMake sure the power supply is normal household volt-

age, 240 volts, 50 Hz, AC only.

nConnect the charger to the power supply.

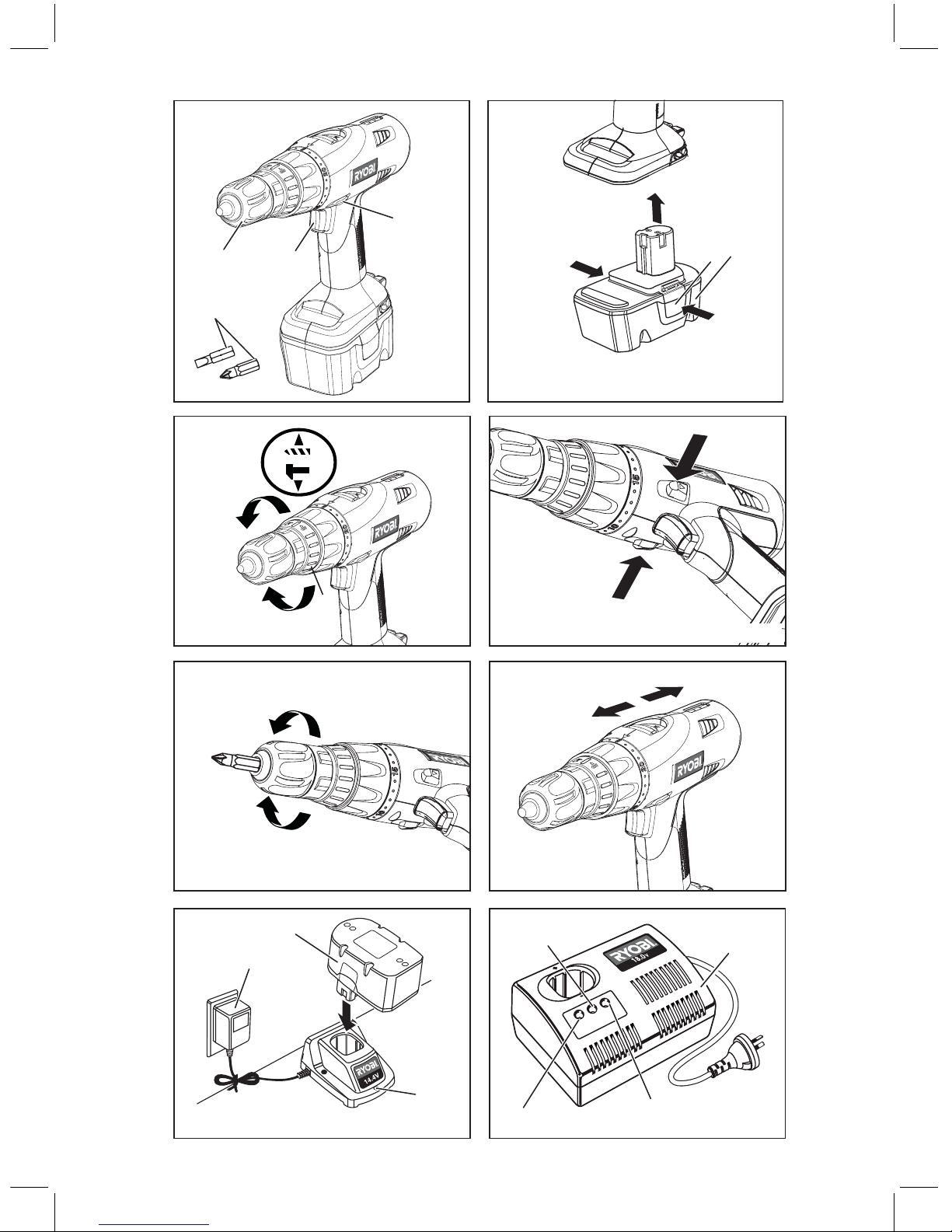

nPlace the battery pack in the charger aligning raised

rib on the battery pack with the groove in the charger.

See Figure 8.

nPress down on the battery pack to be sure contacts

on the battery pack engage properly with contacts in

the charger.

nNormally the red LED on charger will come on. This

indicates the charger is in fast charging mode.

nRed LED should remain on for approximately 1 hour

then the green LED will come on. Green LED on in-

dicates battery pack is fully charged and charger is in

maintenance charge mode.

NOTE: The green LED will remain on until the battery

pack is removed from the charger or charger is discon-

nected from the power supply.

nIf both yellow and green LEDs come on, this indicates

a deeply discharged or defective battery pack.Allow

the battery pack to remain in the charger for 15 to 30

minutes. When the battery pack reaches normalvoltage

range, the red LED should come on. If the red LED

does not come on after 30 minutes, this mayindicate

a defective battery pack and should bereplaced.

nAfter normal usage, a minimum of 1 hour of charging

time is required to fully recharge battery pack.

nThe battery pack will become slightly warm to touch

while charging. This is normal and does notindicate a

problem.

nDo not place the charger and battery pack in an area

of extreme heat or cold. They will work best at normal

room temperature.

NOTE: The charger and battery pack should be placed

in a location where the temperature is more than 10°C

but less than 38°C.

nWhen batteries become fully charged, unplug the-

charger from power supply and remove the battery

pack.

CHARGING A HOT BATTERY PACK

When using the tool continuously, the batteries in the bat-

tery pack will become hot. You should let a hot battery pack

cool down for approximately 30 minutes before attempting

to recharge. When the battery pack becomes discharged

and is hot, this will cause the green LED to come on in-

stead of the red LED. After 30 minutes, reinsert the battery

pack in the charger. If the green LED continues to remain

on, return battery pack to your nearest Ryobi Authorised

Service Centre for checking or replacing.

NOTE: This situation only occurs when continuous use of

the tool causes the batteries to become hot. It does not

occur under normal circumstances. Refer to “CHARGING

A COOL BATTERY PACK” for normal recharging of batter-

ies. If the charger does not charge your battery pack under

normal circumstances, return both the battery pack and

charger to your nearest Ryobi Authorised Service Centre

for electrical check.

TO INSTALL BATTERY PACK

nLock switch trigger on your drill by placing the direction

of rotation selector in center position. See Figure 4.

nPlace battery pack in your drill. Align raised rib on bat-

tery pack with groove inside drill. See Figure 2.

nMake sure the latches on battery pack snap in place

and battery pack is secured in drill before beginning

operation.

TO REMOVE BATTERY PACK

nLock switch trigger on your drill by placing the direction

of rotation selector in center position. See Figure 4.

nLocate latches of battery pack and depress to release

battery pack from your drill. See Figure 2.

nRemove battery pack from your drill.

960931156-01.indd A6960931156-01.indd A6 8/15/02 2:00:29 PM8/15/02 2:00:29 PM