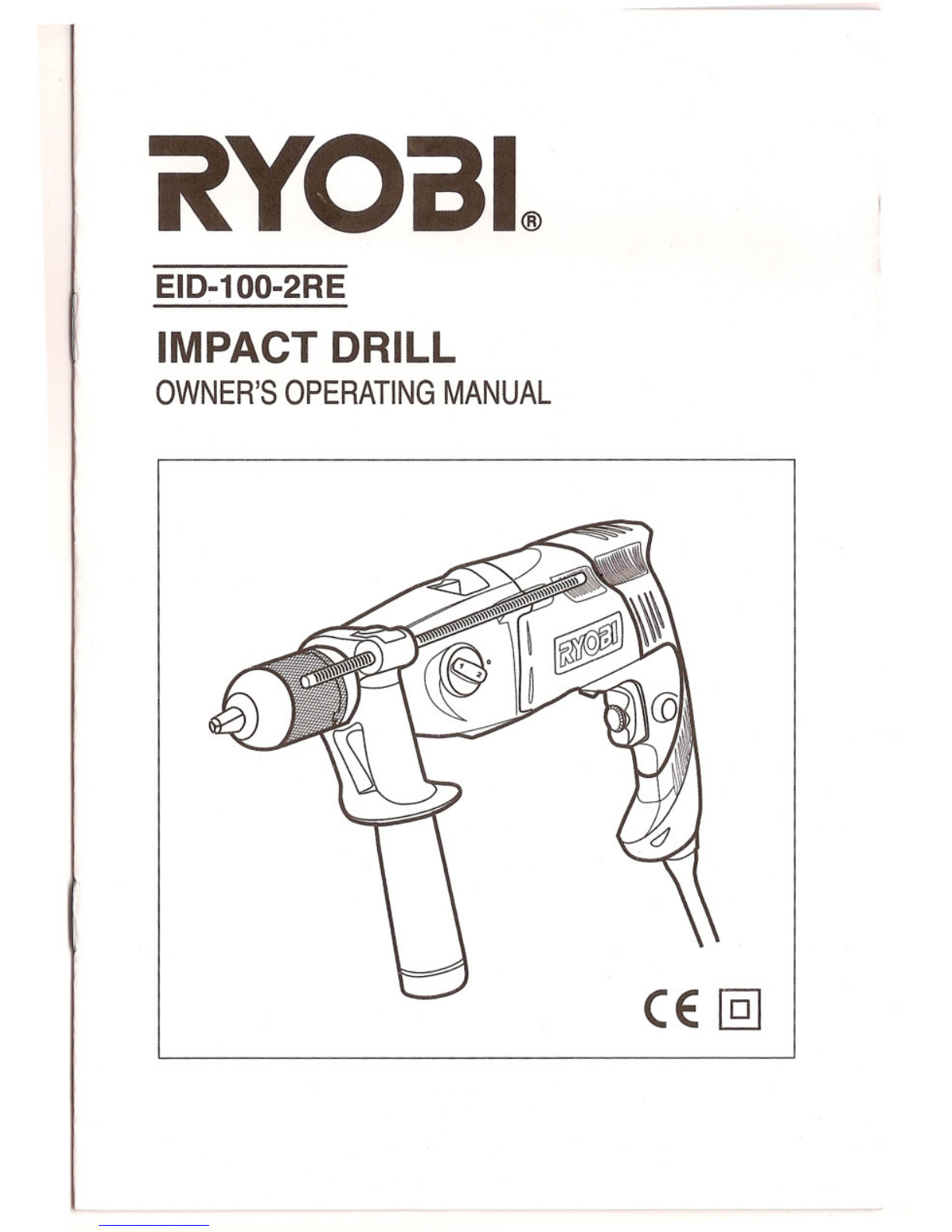

INSTRUCTIONS FOR SAFE HANDLING

English

SWITCH(FIG.1 &3)

.Make sure that the drill bit Is securely mounted. An

Incorrectly mounted bit Is extremely dangerous since

it can fly off or break during drilling.

. Dress properly. Do not wear loose clothing or

jewellery, they can be caught In moving parts.

Protective gloves and non-skid footwear are

recommended when working outdoors. Wear

protective hair covering to contain long hair.

.Hold the tool securely with both hands. If not held

securely, accidents or injury may result.

. Never touch the chuck or metal body parts when

drilling walls, floors, or other surfaces covering

electrical wiring. Hold the tool only by the plastic

handle to prevent electric shocks.

. While operating, the work piece must be securely

held with a vice or clamp etc. to prevent it from

moving due to the drill rotation.

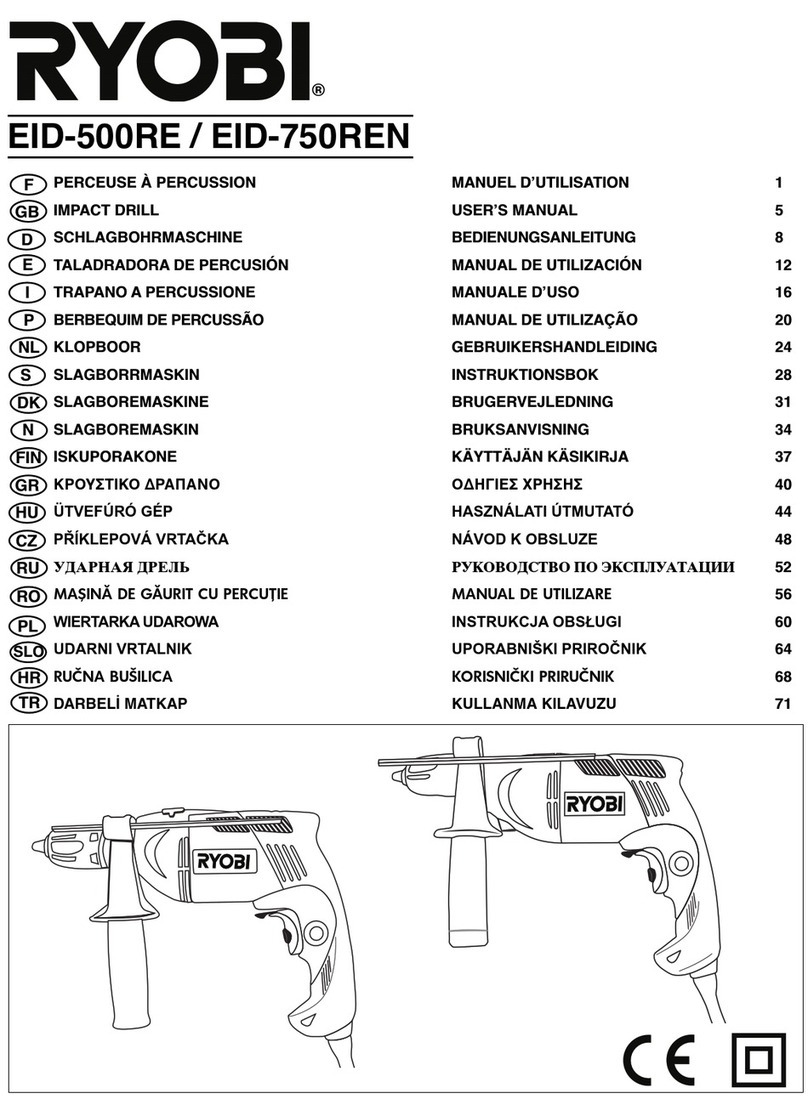

SPECIFICATIONS

Voltage

Chuck capacity

Drilling capacity

inwood

insteel

in masonry

110V1230V-50Hz

13mm(1/2")

40mm

13mm

16mm

1050W

Input

No load speed

high

low

Blows per minute

high

low

Netweight

Safety class II

o.2,880min"

o - 1,300 min"

o - 46,080 min"

o - 20,800 min"

3.2kg

STANDARD ACCESSORIES

Auxiliary handle, Depth Stopper and Drill Bit.

APPLICATIONS. .

(Use only for the purposes listed below.)

.Drilling wood, materials and resin boards.

. Drilling concrete (impact drilling only).

.. Drilling metal, steel, brass, aluminum sheets,

stainless steel & pipe.

NOISE BUilD-UP

Noise (sound pressure level) In the workplace can

exceed 85 dB (A). In this case, sound insulation and

hearing protection measures must be taken by the

operator.

.This tool Is started and stopped by pressing and

releasing the trigger switch (A).

.The speed can be adjusted in either gear by

controlling the force applied to the trigger.

. The maximum speed of the drill may be set at

different speeds by adjusting the variable speed

selector (D).

.For continuous operation, press the lock button (E)

while squeezing the trigger. Squeeze the trigger again

to release the lock.

CHANGING THE ROTATION DIRECTlON(FIG. 2)

.To change the direction 01 rotation, stop the tool and

push the forward 1reverse button (B).

.When the forward button Is pushed In, the bit rotates

clockwise when vlawed from the handle end of the

tool.

.When the reverse button Is pushed In, the bit rotates

counterclockwise.

SPINDLE LOCK ,

For lIasy changing of the drill bit, this drill is equipped

with an automatic spindle lock which holds the spindle

stationary when loosening and tightening the chuck.

WARNINGI

AAlways be sure the spindle lock button Is

released and the spindle lock is disengaged

before turning the drill ON.

MOUNTING AND REMOVING THE BIT(FIG. 4)

.Insert the drill bit (J) Into the chuck as far as the plain

part of its shank will go.

.Tighten the chuck securely by rotating the chuck

head clockwise.

.The bit can be removed by rotating the chuck

counter-clockwise.

CHANGING BETWEEN DRilLING AND IMPACT

DRilLING MODE (FIG. 5)

The drilling mode shift knob (F) for changing between

the drilling mode and impact drilling mode is positioned

on the top of the tool.

DRILLING MODE: Shift the knob to the" ..,. "

symbol for rotation without Impact action.

IMPACT DRILLING MODE: Shift the knob to the" ... "

symbol for Impact drilling.

2

English

OPERATION

NEVER COVER THE AIR VENTS (K) SINCE THEY

MUST ALWAYS BE OPEN FOR PROPER MOTOR

COOLING.

DRilLING IN WOOD

To prevent ugly splits around the drill hole on the reverse

side of the workpiece, put a piece of scrap timber under

the work piece.

DRilLING IN METAL

Metals such as steel, brass,aluminum sheets, stainless

steel, and pipe may also be drilled. Mark the point to be

drilled with a nail or punch.

Do not use impact mode on these materials.

DRilLING IN CONCRETE

Stone and masonry are generally drilled in the Impact

.drilling mode.

When drilling in delicate materials such as wall tiles, it is

essential to start with ordinary drilling and, once the tile

is pierced, to continue with impact drilling.

In deep bore holes the drill bit should be pulled out

occasionally in order to remove the debris from the drill

and hole.

AUXILIARY HANDLEAND STOPPERPOLE

(FIG. 6)

Auxiliary handle

The auxiliary handle (I) can be rotated 360.

loosen the handle grip by turning in direction L,

and tighten it at an easy to-use position by turning

the grip in direction M.

BIT STORAGE (FIG. 7)

The auxiliary handle also contains a compartment to

store drill bits. To access this compartment unscrew the

end cap below the Yellow trim on the handle In an

anticlockwise direction.

DEPTH STOPPER .

Holes of a fixed depth can be accurately bored by using

the depth stopper (G).

The depth of the hole will be the distance from the end

of the bit to the end of the stopper pole.

By turning the handle grip in direction L, the stopper pole

can be released and the depth adjusted. After adjusting

the depth, fix the stopper pole again by turning

the handle grip in direction M.

CHANGING THE ROTATION SPEED (FIG. 8)

The rotation speed can only be changed when the tool

is at a standstill.

The gear setting knob (H) is on the left side of the

housing.

When the knob is in position "1" the tool is in the low

gear.

When the knob is in position "2" the tool is in the high

gear.

LIVE TOOL INDICATOR

This tool features a live tool indicator (L) which

illuminates as soon as the tool is connected to the

supply. This warns the user that the tool is connected and

will operate when the switch is pressed.

MAINTENANCE

After use, check the tool to make sure that it is in good

condition. It is recommended that you take this tool to

a RYOBI Authorized Service Center for a thorough

cleaning and lubrication at least once a year.

DO NOT MAKE ANY ADJUSTMENTS WHILE THE

MOTOR IS IN MOTION.

ALWAYS DISCONNECT THE POWER CORD FROM

THE POWER SUPPLY BEFORE CHANGING

REMOVABLE OR CONSUMABLE PARTS (BLADE,

BIT), BEFORE LUBRICATING OR WORKING ON

THE UNIT.

WARNING'

ATo ensure safety and reliability, all repairs should

be performed by an AUTHORIZED SERVICE

CENTER or other QUALIFIED SERVICE

ORGANIZATION.

SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE.

3