Page 1 of 20

THIS INSTRUCTION GUIDE CONTAINS IMPORTANT INFORMATION.

PLEASE READ CAREFULLY AND STORE IN A SAFE PLACE.

INTRODUCTION

Congratulations! The Specialized Shiv TT is among the finest advanced composite products available in cycling. Carbon fiber is a very special material

that requires particular care during assembly, storage and riding. This instruction guide contains instructions and warnings, plus torque specifications,

to be used in conjunction with the owner’s manuals and instruction guides supplied with your bicycle.

WARNING! Failure to follow these instructions may result in a catastrophic failure of the frame and/or its components while riding, which

may result in serious personal injury or death.

WARNING! Bicycle assembly is a complicated task which requires training and experience. Do not attempt installation of any component

if you do not have experience and training as a bicycle mechanic. Failure to follow this warning may result in serious personal injury or

death. Reference should also be made to Barnett’s or some other comprehensive bicycle manual.

WARNING! Failure to follow the torque specifications in this guide will void your warranty, but most importantly may result in damage to the crank

which may not be visible. If the frame or any components are damaged, this can result in loss of structural integrity, which may result in serious personal

injury or death. To ensure the best assembly possible and to prevent any damage to the frame and components, follow all torque specifications.

WARNING! When placing the frame and/or bicycle in a repair stand, clamp the stand using a frame clamp specifically designed for

thin-wall carbon tubes (for example, the Park Tools 100-X4 Extreme Range Clamp). Clamping the frame with a standard clamp can

cause damage to the frame that may or may not be visible.

TOOLS REQUIRED:

2, 2.5, 3, 4, 5mm Allen keys

4, 5mm socket-style Allen keys

10mm wrench

Torque wrench

High quality grease

Blue threadlocker (Loctite 242)

Cable and housing cutters

Flathead screwdriver (notched)

FRAME PREPARATION

CAUTION: Do not face or ream bottom bracket shell! This can possibly prevent proper installation of the crank. Your Specialized frame does

not require any Bottom Bracket shell pre-installation preparation, all surfaces have been precisely machined to specific tolerances at the

factory for proper interface with the S-Works Carbon crankset.

WARNING! Great care should be taken to not damage carbon fiber or composite material. Any damage may result in a loss of structural

integrity, which may result in a catastrophic failure. This damage may or may not be visible in inspection. Before each ride, and after any

crash, you should carefully inspect your bicycle for any fraying, gouging, scratches through the paint, chipping, bending, or any other

signs of damage. Do not ride if your bicycle shows any of these signs. After any crash, and before you ride any further, take your bicycle

to an authorized Specialized retailer for a complete inspection.

WARRANTY

For the complete warranty provisions, please refer to www.specialized.com.

Please note all instructions are subject to change for improvement without notice.

Please visit www.specialized.com for periodic tech updates.

Feedback: techdocs@specialized.com

SPECIALIZED BICYCLE COMPONENTS

15130 Concord Circle, Morgan Hill, CA 95037 (408) 779-6229

IG0333 Rev.B, March 2011

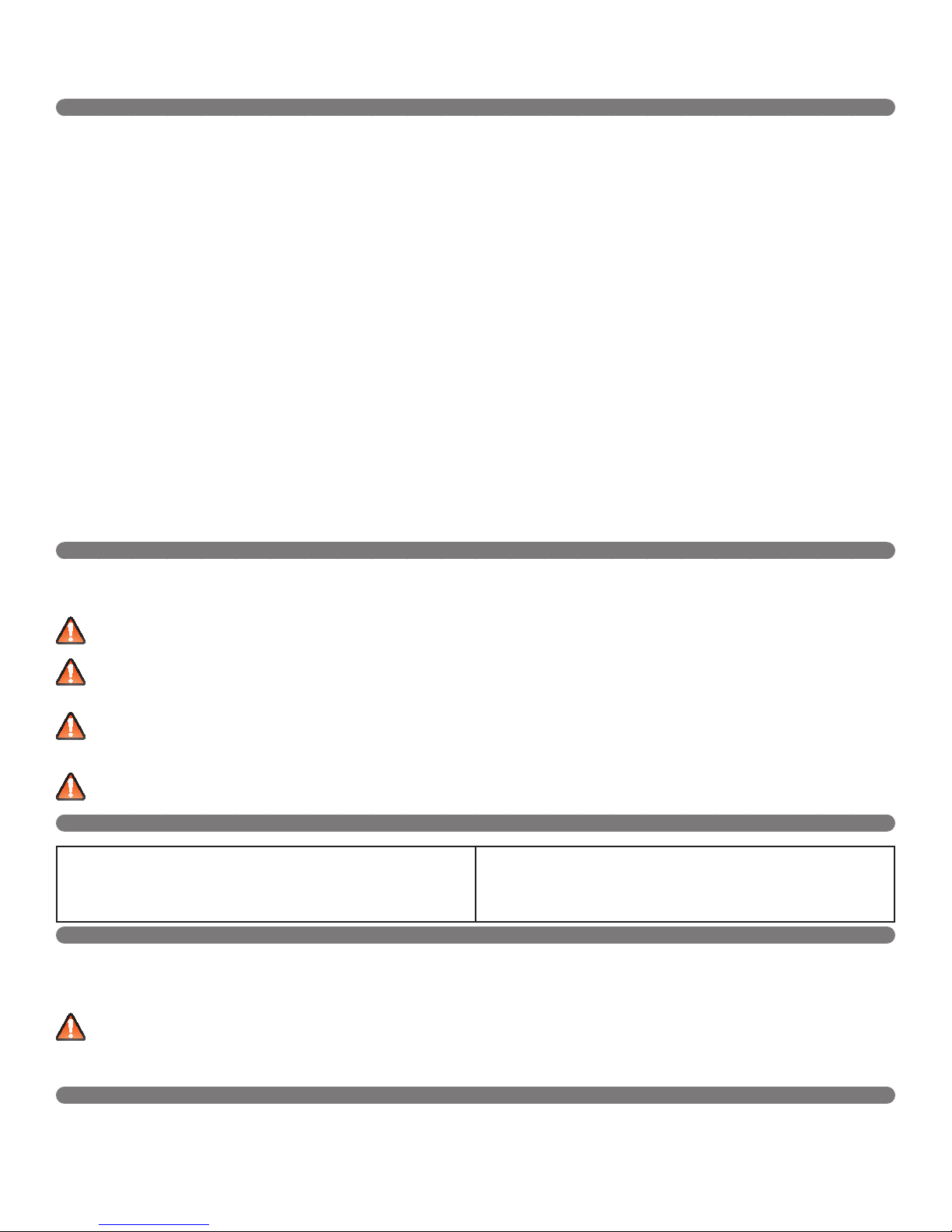

TABLE OF CONTENTS

INTRODUCTION .........................................................................1

TOOLS REQUIRED: ......................................................................1

FRAME PREPARATION ...................................................................1

WARRANTY ............................................................................1

HARDWARE ............................................................................2

GEOMETRY ............................................................................4

CHAPTER 1: HANDLEBAR / STEM INSTALLATION ..............................................6

1.1 INSTALLING THE CABLES IN THE HANDLEBAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 INSTALLING THE BRAKE LEVERS IN THE HANDLEBAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

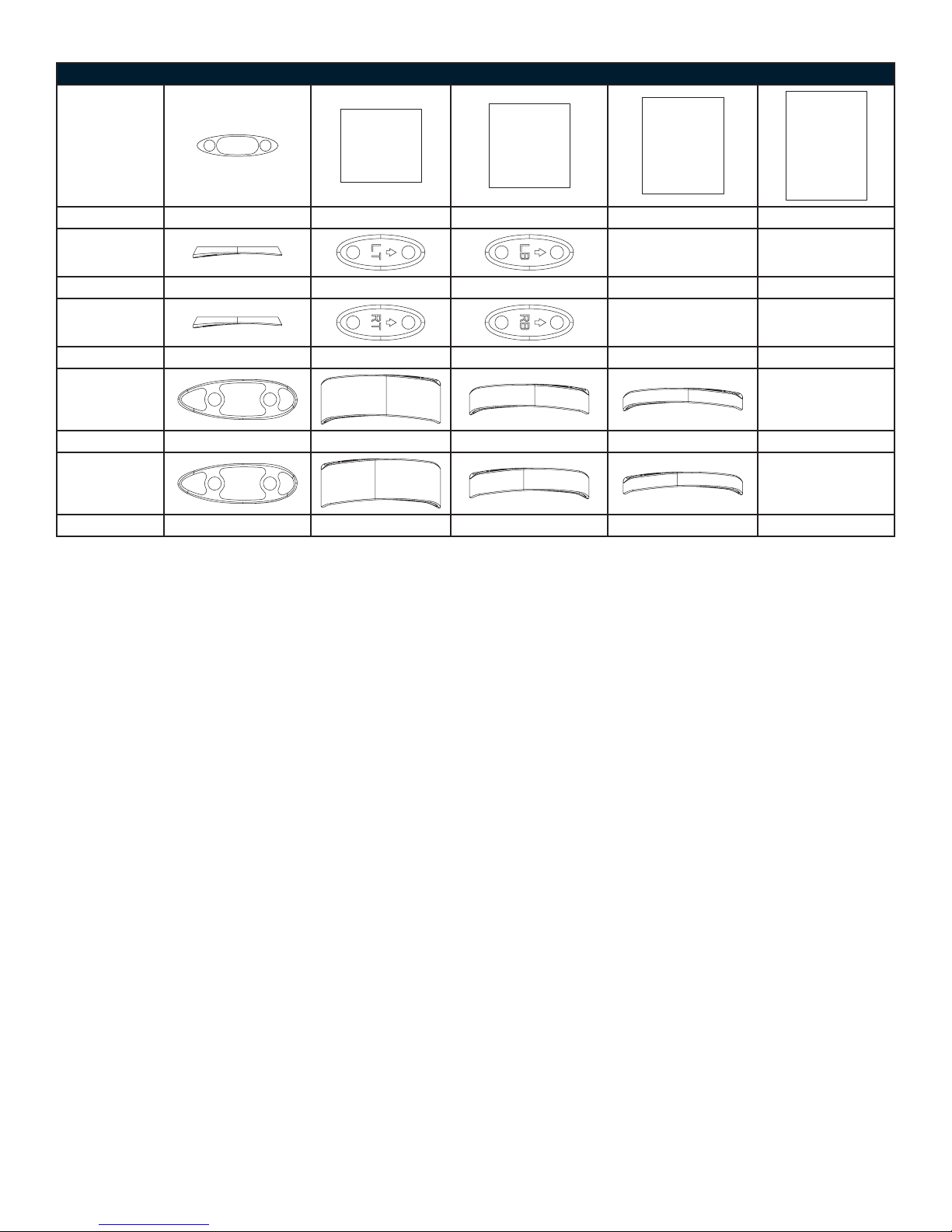

1.3 INSTALLING THE HANDLEBAR ON THE STEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 INSTALLING THE FRONT END ASSEMBLY ON THE FRAME. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CHAPTER 2: BRAKE INSTALLATION ........................................................10

2.1 FRONT AND REAR BRAKE ASSEMBLY (Exploded view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 FRONT AND REAR BRAKE ASSEMBLY (Spring mechanism) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 INSTALLING THE FRONT BRAKE ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 INSTALLING THE REAR BRAKE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CHAPTER 3: HANDLEBAR EXTENSION INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 INSTALLING THE AERO EXTENSIONS (Option 1 - no risers, with our without spacers) . . . . . . 15

3.2 INSTALLING THE RISERS AND CROSSBAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 INSTALLING THE AERO EXTENSIONS (Option 2 - risers with or without spacers) . . . . . . . . . 17

3.4 AERO EXTENSIONS WITH SPACERS AND RISERS - FULL RANGE . . . . . . . . . . . . . . . . . . . . 17

3.5 INSTALLING THE ARMRESTS ........................................................18

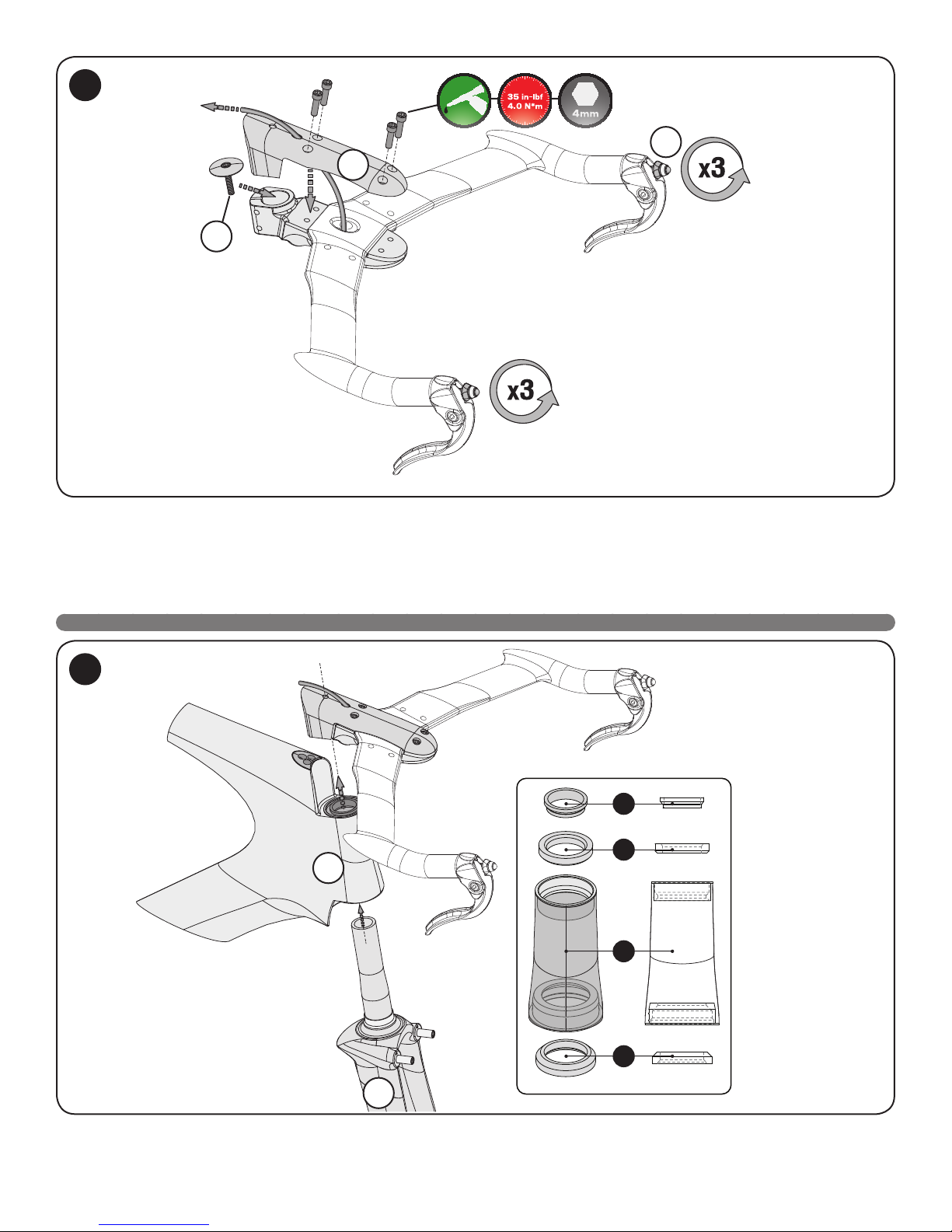

CHAPTER 4: SEATPOST INSTALLATION .....................................................19

4.1 INSTALLING THE SEATPOST CRADLE ASSEMBLY IN THE SEATPOST . . . . . . . . . . . . . . . . . 19

4.2 ADJUSTING THE SEATPOST TILT ANGLE AND FORE-AFT POSITIONS . . . . . . . . . . . . . . . . 19

4.3 INSTALLING THE SEATPOST COLLAR AND SHIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20