T120C

II

3.3.3 Machine cleaning 21......................................................

3.4 MACHINE CONNECTION WITH THE POWER SOURCES 21.....................

3.4.1 Connection with the electric system 21.......................................

3.4.2 Check of the rotating direction 22...........................................

3.4.3 Connection with the suction system 22.......................................

4 MACHINE START-UP AND USE 25......................................

4.1 CONTROL LIST AND FUNCTIONS 25.........................................

4.2 SPINDLE POSITIONING 26..................................................

4.3 PREVENTIVE CHECKS 26...................................................

4.4 TOOLS 26..................................................................

4.4.1 Features of the tools that can be installed 26.................................

4.4.2 Tool handling 27..........................................................

4.5 INITIAL ADJUSTMENTS AND OUTFIT 28......................................

4.5.1 Installation of the interchangeable spindle 28.................................

4.5.2 Removal of the interchangeable spindle 29...................................

4.5.3 Tool installation on the spindle 30...........................................

4.5.4 Selection of the tool rotating speed 32.......................................

4.6 SAFETY OPERATING PROCEDURES 35......................................

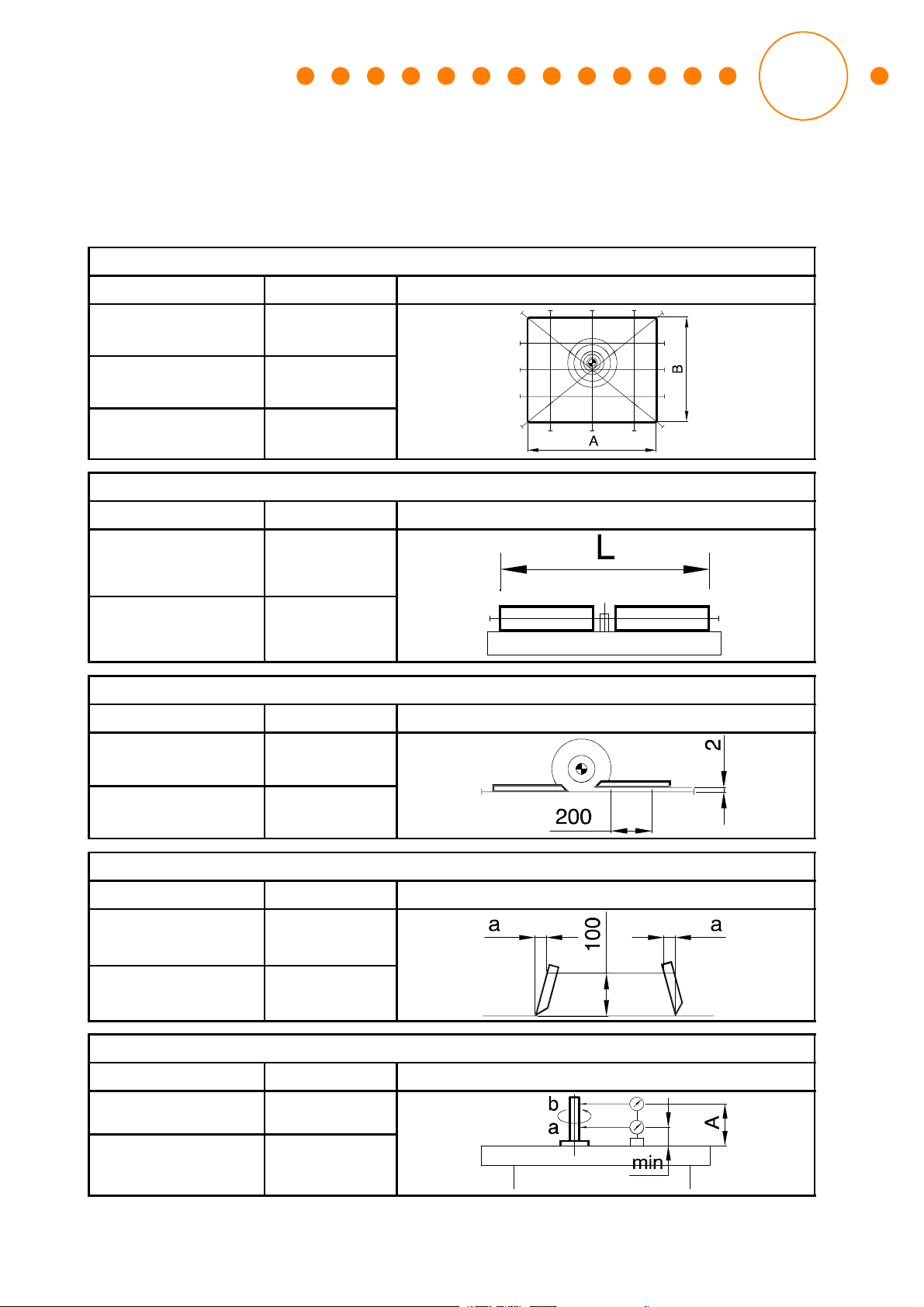

4.6.1 Dimensions of the pieces being machined 35.................................

4.6.2 Machine adjustment and installation 36......................................

4.6.3 Tool adjustment on the machine 36..........................................

4.6.4 Guide adjustment 36......................................................

4.6.5 Rotating directions 36.....................................................

4.6.6 Speed selection 36........................................................

4.6.7 Machine operation, guard choice and adjustments 36..........................

4.6.8 Guide machining with cutting through all the piece length 37....................

4.6.9 Interrupted machining 37...................................................

4.6.10 Shaft machining 38........................................................

4.6.11 Simultaneous machining 38................................................

4.6.12 Other machinings 38......................................................

4.6.13 Noise reduction 38........................................................

4.7 OPERATING CYCLE 39......................................................

4.7.1 Spindle start 39...........................................................

4.7.2 Use of the machining guide 39..............................................

4.7.3 Pressing device use for the guide machining 42...............................

4.7.4 Use of the machining guide with three positions (optional) 43...................

4.8 GUIDE MACHINING PROCEDURES 45........................................

4.8.1 Guide machining with cutting through all the piece length 46....................

4.8.2 Interrupted machining 46...................................................