Heiniger TPW Aussie Xpress User manual

T

TP

PW

W

W

WO

OO

OL

LP

PR

RE

ES

SS

S

Operator manual

for models

Aussie Xpress

&

Kiwi Xpress

Read before operating

Manufactured by

HEINIGER AUSTRALIA

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

2

Contents

1General information

1.1 Introduction

1.2 Intended use

1.3 Contact addresses

2Safety

2.1 Safety notice

2.2 Essential operator skills

2.3 Measures for avoiding accidents

3Accepting delivery

4Transporting

5Guarantee

5.1 Introduction

5.2 Guarantee period

5.3 Conditions

6Technical data

6.1 Dimensions

6.2 Electric

6.3 Petrol

6.4 Hydraulic system

6.5 Cycle time

6.6 Weighing system

7Power supply & connections

8Assembly

9Jockey wheel

10 Woolpress operation

11 Weighing system

11.1 Scale operation

11.2 Weighing modes

11.3 System care

11.4 Span calibration procedure

11.5 Avoid overweight bales

11.6 Mechanical considerations

12 Woolpress maintenance

12.1 Safety guard maintenance

12.2 General maintenance

12.3 Daily maintenance

12.4 Monthly maintenance

12.5 Oil change

12.6 Filter change

12.7 Pressure relief valve

12.8 Control valve neutral adjustment

12.9 Baling pin adjustment

12.10 Unpinning clearance

12.11 Hydraulic pump operation

12.12 Pump adjustment procedure

13 Troubleshooting

14 General layout illustration

15 Side view

16 Lubrication points illustration

17 Warranty registration

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

3

1General information

1.1 Introduction

This manual has been compiled to assist in the operation and maintenance of TPW

Woolpresses.

HEINIGER Australia reserves the right to amend, add or delete any parts of these

instructions of specification without notice.

Note: As it is not possible to instruct a person to a competent level in the use of this

woolpress from a manual alone, HEINIGER Australia asserts that the owner/manager of this

woolpress must employ an operator who will be familiar with wool pressing in general and

has an understanding of the process and some terminology or else will be instructed and/or

supervised by a person with these requisites. Regardless of this the person operating this

press must be able to read and understand this manual

If this is not the case then no attempt should be made to use this press.

1.2 Intended use.

The TPW Woolpress is designed, manufactured and supplied for pressing wool. Other uses

are expressly prohibited

The details in 6Technical data, count as mandatory operating limits and ratings.

1.3 Contact addresses

HEINIGER Australia

5A Tayet Link

Bibra Lake, Western Australia 6163

T: +61 8 9434 0000

F: +61 8 9434 0011

E: mail@heiniger.com.au

W: www.heiniger.com.au

HEINIGER New Zealand

1B Chinook Place

Hornby Christchurch

T: +64 3 349 8282

F: +64 3 349 8292

E: mail@heiniger.co.nz

W www.heiniger.com

HEINIGER Australia

5 Devon Street

Lonsdale, SA 5163

T: +61 8 8326 0890

2Safety

2.1 Safety Notice

HEINIGER Australia has fitted this woolpress with safety devices to help protect the operator

during use. Should these safety devices become inoperable for any reason, it is the

responsibility of the owner to ensure it is repaired before further use. All defects should be

reported immediately to your supervisor.

It is an offence to operate this woolpress without the safety device fitted and in proper

working order.

2.2 Essential operator skills

The owner/manager of this woolpress has an obligation to ensure that the operator is

competent to use the press.

Operating the press safely only makes small demands of the operator. It is essential that

they are observed and carried out.

The operator must have read and understood the manual or have been instructed in the

operation of the press by a skilled person and have had the potential dangers pointed out to

him. The operator shall be able to demonstrate an understanding of the press controls and

the hazards associated with the press.

The continued effectiveness of the safety device shall be tested by the operator prior to the

start of each shift of pressing, and at any time the operator has reason to suspect failure of

any safety device component.

It is an offence to operate the press without the safety device fitted in proper working order.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

4

2.3 Measures for avoiding accidents.

➢Do not reach into any part of the woolpress while it is operating

➢Store the woolpress in a dry undercover area when not in use

➢Avoid getting electrical components of the woolpress wet

➢Hang the power cable from the roof to avoid a tripping hazard and to avoid damaging

the cord. Ensure the cord will not get caught in moving parts at the top of the

woolpress

➢After use disconnect the power

➢Switch the woolpress off before disconnecting the power

➢Never leave the woolpress unsupervised when connected to the power

➢Avoid kinks and tight coils in the cable when storing, this can damage the cable

➢The operating instructions must be kept safely and accessible to the operator at all

times

➢Do not wear loose clothing or jewellery when using this woolpress, tie back long hair

➢The safe guards fitted to this woolpress must be kept in proper condition

➢The safe guards must be fitted and operational before using this woolpress

➢Children are not permitted to use the woolpress

➢Children are not permitted in the vicinity of the woolpress when it is being operated or

maintenance is being carried out

➢Never use a damaged woolpress. Have the woolpress repaired by an authorized service

agent or qualified technician

➢Any damage to or failure of the woolpress which may constitute a risk to the health and

safety of any person shall be immediately reported by the operator to the

owner/manager who shall take appropriate action

Examples of the type of damage which would constitute such a risk include:

➢Damage to any part of the woolpress

➢Frayed or damage insulation on electrical wiring;

➢Cracked, perished or damaged hydraulic hoses, pipes or fittings;

➢Overheating of any motor or pump; or

➢Failure or wear of any control or component.

➢Damaged or loose fasteners, nuts, bolts, etc.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

5

3Accepting delivery

All units are transported at the owner's risk.

Before accepting delivery, thoroughly inspect the Woolpress for damage.

If any has occurred you should note the nature and extent of the damage in view of any

insurance claim you may wish to make.

Whilst all care is taken during manufacture and by our agents to ensure your woolpress

arrives in perfect working order and condition, damage occurring during transit or faulty

operation resulting from damage occurring during transit will not be covered by our

warranty.

The following areas should be checked carefully:

➢Guide rods, including the return bolt and the adjustable pinning lug, these must be

present and secure.

➢The pinning guards. They should locate securely in place.

➢Check scale components, indicator, cords and fittings.

➢Electrical components etc (where fitted).

➢Petrol Engine (when fitted).

➢All ancillary equipment, i.e. panels, axles, wheels, jockey wheel, etc

➢Hydraulics, Check for leakage at all connections and damage to hoses etc.

➢Check fluid levels.

➢Check that safety devices are operating correctly.

➢Electric motor (where fitted) Fan cover etc.

4Transporting.

The TPW Woolpress is supplied on transport skids. It is advisable to use the transport skids

whenever practicable when transporting the woolpress.

Ensure that there is no load on the load cell or wheels and the hydraulic cylinder is lowered.

A Woolpress Trolley is available, to enable easy movement from shed to shed. The trolley

should only be used when it is safe to do so.

When moving the press with the transport skids fitted it is advisable to:

➢Use only a forklift truck that is adequate for the task.

➢Use only a driver qualified to operate the forklift truck.

➢Only move over a stable, level surface.

➢Lift only from the bottom of the woolpress between the transport skids and the base of

the press.

➢Lift only from the front or rear of the woolpress.

➢Spread the forks as wide as possible within this space.

➢Ensure that the woolpress is fully on the forks before lifting.

➢Keep the woolpress as close to the ground as possible when moving.

➢Move no faster than walking pace.

➢Take care when turning corners and stopping as the woolpress may slide on the forks.

➢Lower the woolpress gently.

➢Only lower the woolpress onto a stable, level surface.

Because of the woolpresses height and centre of gravity when the hydraulic cylinder is in its

operating position it can be unstable when being moved, for this reason it is advisable to

fold the cylinder down when transporting.

Even when the cylinder is folded down care needs to be taken when transporting.

When the press is delivered from the factory the cylinder will be in the folded down position.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

6

5Guarantee

5.1 Introduction

HEINIGER Australia guarantee the 'TPW Woolpress" manufactured by them to be free from

defect in workmanship and materials. Their obligations pursuant to this guarantee are

limited to the repair or replacement of parts and workmanship which prove defective within

the specified period.

The repair or replacement shall be affected upon the defective equipment being returned

freight pre-paid to the registered office of HEINIGER Australia or New Zealand or when

authorised to the authorised Service Agents.

All travelling costs incurred by Service Agents performing repairs under warranty will be the

owner’s responsibility.

Where HEINIGER Australia supplies goods not manufactured by HEINIGER Australia, the

customer shall only be entitled to such benefits as HEINIGER Australia may receive under

guarantee as given to HEINIGER Australia by the manufacturer of those goods.

Some parts not covered by HEINIGER Australia

Hydraulic Cylinder, Hydraulic hoses, Electric motor, Hydraulic pump assembly, Hydraulic

control valve, Starter switch, Scale components.

(These parts generally have to be sent back to the manufacturer for warranty inspection

and assessment)

5.2 Guarantee period on parts manufactured by HEINIGER Australia

Primary producers: 25 months from the date of delivery.

Contractors: 12 months from the date of delivery.

5.3 Conditions

This guarantee will be invalidated for any of the following reasons:

1. If notice of the defect is not given to HEINIGER Australia or New Zealand within the

guarantee period.

2. If the woolpress has been subject to misuse, abuse, negligence or accident.

3. If the woolpress is installed, maintained or operated in any manner other than that for

which it is designed.

4. If the woolpress is used for any duty or subjected to any abnormal operating conditions

varying from that for which it is supplied by HEINIGER Australia.

When making a warranty claim or ordering new parts, it is important that the serial number

of the unit is quoted and the date of purchase stated.

6Technical data

6.1 Dimensions

Height operational: 2705mm

Height shipping: 1970mm

Box height: 1185mm

Length: 1390mm

Width: 970mm

Weight: 530kg

6.2 Electric

Motor: Teco Induction

Electric: 4kw (5.5hp), 415V, 3Ø, 1440rpm

Electric: 2.2kw (3hp), 240V or 480V at 1460rpm

Electrical operating voltage and current:

Nominal Min Volts Return stroke Full load

Volts Full load Current Current

240 V 220 V 11.0A 16.0A

480 V 440 V 6.0A 8.0A

415 V 8.0A 8.0A

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

7

6.3 Petrol

Engine: Honda 11 hp, Rope or Electric start.

Battery not supplied.

Remote power pack.

6.4 Hydraulic system

Oil capacity: 25 Litres

Oil type: Mobil DTE 24 or equivalent

Oil filter: Inline suction, 25 micron

Pump: Nachi PVS-IB-22 Variable displacement piston pump.

Discharge at 1460 rpm: 30 L/min @ 0-5 Mpa, and 7L/min @ 5-18 Mpa.

Control valve: Oilpath OP20 2000

Cylinder: G&R 88.9mm bore by 740mm stroke.

Pressure relief: 18,000kpa (2600psi)

6.5 Cycle time Empty Full bale

With 240 V or 480 V: 12 seconds 16 seconds

With 220 V or 440 V: 13 seconds 20 seconds (low power supply)

6.6 Weighing system

Make: Iconix FX1

Indication: LCD

Power supply: 12V DC

Load sensing: Single load cell

Zero facility: Automatic zero tracking or by zero facility.

Calibration: Factory calibrated

Memory: Will retain last shown weight indefinitely.

Range 1.0 kg -750kg.

Specifications subject to change without notice.

Designed to comply with current Occupational Safety and Health regulations.

6.7 IP Rating

Product

IP Rating

Information

Contact

5.5kw cast frame TECO Motor

IP 56

TECO NZ

Mohammad TECO

Technician Auckland

2.2kw cast frame TECO Motor

IP 44

TECO NZ

Mohammad TECO

Technician Auckland

SS Switch + button

IP 65

NAW

Luke Sales Tech Melbourne

DOL Switch + button

IP 65

NAW

Luke Sales Tech Melbourne

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

8

7Power supply & connections.

It is the responsibility of the owner to ensure correct power supply.

➢The voltage specified on the electric motor manufacturers plate and that of the local

power supply must match. The press motor may only be connected to an AC power

supply.

➢In the event that the press is operated from a generator, the mains supply voltage

must not exceed that specified on the manufacturer’s plate.

➢Never plug the press into damaged sockets.

➢Observe the relevant regulations applicable in your country.

➢Completely unroll the power cable before plugging in.

➢If a 3 phase motor is fitted the rotation must be checked prior to using the press.

Correct rotation direction is indicated on the pump.

Note: Damage to woolpress components caused by incorrect power supply will not be

covered by warranty.

8Assembly

Note: Before assembling the woolpress ensure that there is adequate headroom for the

woolpress. (see 6 Technical data)

Note: DO NOT cycle the woolpress with an empty wool pack in the chamber, damage to

the press and pack will occur.

Warning: Always ensure the control valve handle is in the neutral (centre) position before

starting the motor.

For assembly of the woolpress, the following procedures must be carried out:

1. Note the IMPORTANT sticker on the press, which emphasises the need for the owners

and operators to read the operators manual and to complete and return the warranty

card.

2. Check the level of hydraulic oil (100mm from the top +/- 25mm) and crankcase oil

level on petrol driven models.

3. Check the correct voltage is being supplied e.g. 240 volt or 480 volt. If 3 phase check

motor rotation. If incorrect an electrician should reverse. If an extension lead must be

used, it must be a 20 amp lead. Avoid leads longer than 10m.

4. Cut the cable ties that fasten the platen to the support bars, remove the nuts and

washers from the cylinder mounting bolts.

5. With the control valve handle in the neutral or centre position, start the motor.

6. If the starter switch chatters and will not engage during start up, suspect low voltage

power supply. An electrician should check the supply voltage under starting load and

full load.

Warning: When using the hydraulics to raise the cylinder as described here, the motion of

the cylinder does not appear consistent with the action of the handle, ie, when you pull the

handle down the cylinder moves up. It is important to be aware of how the press will react

to the movement of controls.

Warning: There is a pinch hazard between the flange plate of the cylinder and the top

cross members of the press. Keep hands and fingers clear of the cylinder flange while

raising the cylinder.

Warning: When raising the platen for the first time ensure that the top of the right hand

guide rod does not get caught under the cylinder hydraulic hoses. If the guiderod is too

close to the hoses, stop the platen and pull the hoses out of the way. The hoses must be

restrained so that at no time can they get caught on the guide rod. If the guide rod does

get caught on the hoses significant damage will occur to the woolpress. This damage will

not be covered by warranty.

7. To extend the cylinder upward towards the crossbeam, ease the control valve handle

down. Rotate the cylinder casing if necessary to align it with the mounting bolts. Keep

hands clear of cylinder flange while raising the cylinder.

8. Stop the motor.

9. Fit the washers and nuts to the mounting bolts to finger tight only.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

9

10. Start the motor and ease the control valve handle up to raise the platen until the

unpinning post pins are level with the tips of the pawls when the pawls are held with

the tip at its lowest possible point (see illus at 12.10). Stop the motor.

Warning: Do not attempt to hold any part of the press components (accept for the control

valve handle) when raising the cylinder or platen.

11. Ensure that the gap between the tip of the pawl and the unpinning post pin is even on

both sides. (see illus at 12.10)

12. Tighten the mounting bolts & nuts securely. Remove the support bars from the press.

13. Fit the load cell foot and remove the transport feet.

14. Adjust the load cell foot so the press is level. Tighten the load cell foot lock nut against

the load cell.

15. Secure the jockey wheel in its catch and check to ensure that the jockey wheel brake

foot is clear of the floor.

16. Fit the indicator onto its bracket and plug the load cell lead into the indicator.

17. With the press closed, plug the power supply in, then switch on using the ON/ZERO

key. The display should indicate zero, ▲. If not press ON/ZERO. Applying weight to

the press structure should register a reading.

18. Before operating the wool press, lubricate all moving parts. When the bellcranks and

baling pins are lubricated fit the pinning guards. (see illus)

19. Start the woolpress and cycle it a few times to expel any air, which may be trapped in

the hydraulic system.

9Jockey Wheel

To use the Jockey Wheel pull it free of the catch and lower it towards the floor, this

transfers the weight of the woolpress from the loadcell foot to the Jockey Wheel.

The woolpress is now ready to move.

To use the brake foot lift the Jockey Wheel handle up about half way, retain a firm grip on

the handle, when the brake foot contacts the ground it will stop the woolpress.

When the woolpress has come to a complete stop lift the Jockey Wheel up and push the

plastic knob firmly into the catch to secure it.

Note: When pressing wool ensure that the Jockey Wheel is secured in the catch and the

loadcell foot is fitted to the correct height so the brake foot on the Jockey Wheel is clear of

the floor.

When moving the woolpress the loadcell foot must be clear of the floor.

When using the Jockey Wheel do not release it until it has been secured in the catch. If

released, unrestrained upward movement can cause damage to the woolpress.

Do not allow any part of your body to come between the Jockey Wheel and the woolpress.

When moving the woolpress it is important that it has come to a complete stop before

lowering the weight of the woolpress onto the loadcell foot.

The woolpress should not be used or moved on uneven, unstable or sloping surfaces.

10 Jockey wheel illustration

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

10

Woolpress operation.

1. Close the rear door of the woolpress and secure with the locking bar handle.

2. Make sure the control valve handle is in the neutral position. Switch the press on.

3. With the hungry board and pack lock handle in the closed position turn the scales on

and check that they are reading zero before proceeding.

4. Lift the pack lock handle and the hungry board. Hang the bale ejector belt over the

front, centre of the bin and place the hook into the hook pocket, make sure that the

pins in the packlock handle will not pierce the strap. The doubled over stitched part of

the strap should be level with the bottom of the packlock when it is closed. Place a

pack in the woolpress. Hang the flaps of the pack neatly over the four sides of the

woolpress. The corner stitching should come to the top of the box. Close the hungry

board firmly and secure with the pack lock handle.

5. Ensure that the hook on the hungry board is fitted over the locking bar handle,

preventing the locking bar and door from being opened when the hungry board is

closed.

6. Secure the pack lock handle with the pack lock clamp.

7. Fill the chamber to its maximum with wool. Pull the guard down. This will allow you to

pull the control valve handle into the down position. The control valve handle will not

operate down with the guard up. Then pull the control valve handle into the down

position.

8. On the first pressing only, allow the platen to come down until just before the pins

come in, push the control valve handle to the up position to return the platen to the

top of it's stroke. If needed lift the guard.

9. After the first pressing, load more wool pull the control valve handle down and allow

the press to complete its cycle without interruption. When the platen is returning it will

automatically lift the guard.

Note: If the pressing chamber of the press is not full of wool when the press is cycled the

pack may get pushed into the chamber by the baling pins. If this happens it is possible for

damage to occur to the pack and press.

Note: Always allow the press to complete a cycle. If a cycle is interrupted when the press

is next cycled damage may occur due to the press being out of sequence.

Warning: When the press commences a cycle all parts of the operators body must be

clear of the pressing chamber.

10. During the pressing cycle the operator can get more wool. Continue compressing the

wool until the desired weight has been achieved. HEINIGER recommends 190 -195 Kg

11. Closing off pack. On achieving desired bale weight allow the press to finish the cycle,

while the pins are still in, spread wool evenly by pulling it from the centre of the bale

and placing it to the sides of the press, cycle the press again to re-pin.

12. Open the pack lock clamp and pack lock handle and lift the hungry board, fold the left

flap over the right flap and secure firmly with 3 bale fasteners, then fold the back flap

over the front flap and secure with 4 bale fasteners. (The firmer the flaps -the neater

the bale.)

13. Bale ejection. Close the hungry board and pack lock clamp. Pull the guard down. Pull

the control valve handle down; as the platen descends, the bale pins will automatically

withdraw. Allow the platen to continue downwards until the yellow mark on the right

hand guide rod lines up with the yellow line on the cylinder.

14. Push the control valve handle into the middle/neutral position to stop platen

movement.

15. Lift up the guard and open the pack lock and hungry board.

16. Attach the bale ejector belt hook to the bale ejector catch. Then open the back door.

17. Push the control valve handle up to raise the platen, thus completing the operation

and ejecting the bale through the rear door.

See warnings & notes.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

11

Warning: Do not attempt to eject a bale without first opening the door, substantial

damage to the press will occur otherwise.

18. Disconnect the bale ejector belt from the bale ejector catch. The platen may have to

be lowered slightly to do this. Ensure that the bale ejector belt is placed over the front

of the pressing chamber.

19. Close the rear door of the woolpress and secure with the locking handle.

Note: Ejection from the rear of the press is possible by attaching the bale ejector belt

from the front, move to the rear of the press with a woolbale trolley. Send the hydraulic

ram upwards by pulling down on the yellow handle on the rear of the control valve

linkage, thereby ejecting the bale onto the trolley. Take care not to over balance and get

caught under the ejecting bale and trolley.

Note: If the bale ejector belt is not placed over the front of the pressing chamber prior to

pressing a bale, the bale will have to be unpinned and the wool removed by hand.

Note: If the guard is lifted during operation it will cause the platen to ascend.

The press will not operate in its down cycle with the guard raised or the hungry board

open.

Ensure that the ejection catch is stowed on top of the platen when not in use.

11 Weighing system

11.1 Scale operation

1. Plug the power supply and the load cell into the indicator.

2. Press the ON/ZERO key. The scale will automatically show zero unless weight has

been left on the scale. The ZERO pointer ▲will show that the scale is at zero.

3. If the scale does not show zero, press ON/ZERO.

11.2 Weighing modes

Free mode: Normal weighing mode for woolpresses, Free mode is automatically selected

at switch on. The display is continuously updated with the weight currently on the scale.

Hold mode: A press of the WEIGH key switches the scale to hold mode, which is suitable

for live animal weighing. Hold mode uses an averaging process, which displays the

accurate weight of a moving animal. The weight is locked on the display until the next key

press. To turn the scale back to Free mode press the ON/ZERO key.

11.3 System care

Fit caps to indicator sockets when not in use to protect from dirt and moisture. Hang the

cable ends up out of mud and dust.

Damage may occur if the capacity of the scale is exceeded.

All cables must be kept in good condition.

11.4 Span calibration procedure

Note: The span calibration is performed independently for each scale type.

Note: To ensure that scale accuracy is maintained, the bale used to calibrate the scales

should be as close to the maximum bale weight as possible.

Note: Start with the indicator turned off.

1. Plug the power supply and load cell into the indicator. Remove all live loads from the

press.

2. Hold the WEIGH key down, then press and release the ON/ZERO key, releasing the

WEIGH key when SEt appears.

3. With no weight on the press, zero the scales with the ON/ZERO key.

Note: In step 4. and 5. once ON/ZERO and WEIGH have been pressed simultaneously, if

you do not start weight adjustment within 5 sec then the shown weight will be saved.

4. Re-press a bale of wool of which the exact weight is known. Allow to settle, then press

and release ON/ZERO and WEIGH simultaneously. The display will show SPAn while

weighing the bale, then display to the nearest kilogram, according to the present

calibration. Eg. 0195.

5. Change the displayed weight to the correct weight using ON/ZERO to increase weight

and WEIGH to decrease weight. One press of a key will increase or decrease the

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

12

weight by 1 kg. For large adjustments to the displayed weight hold down the required

key.

6. When the displayed reading is the same as the bale weight, press no keys for 5

seconds. SAVE is displayed as the new calibration is stored in EEPROM.

7. Remove the bale from the press, the scales should return to zero.

Note: Having completed the span procedure the scales should be switched off then on and

checked to confirm accuracy.

11.5 Avoid Overweight Bales.

Heiniger recommends that bale weights are checked for accuracy by using another set of

scales, which are known to be accurate.

The woolpress must be used on a stable, level surface. Any movement in the floor will

affect the performance of the scales.

Keep obstructions free of the press, make sure there is no build up of wool around or

under the press.

Do not move the press halfway through a bale as the zero reference may not be the same.

Ensure scale is on zero each time before putting the pack in.

If you press the ON/ZERO key when you already have the pack in, make sure you allow

2kg for the weight of the pack.

Bale weights.

Because of weight gains due to dampness or humidity, it is suggested to press bales only

to 190/195kg so that bales do not exceed 204kg.

11.6 Mechanical considerations.

The following are the requirements, which are necessary for the electronic scales to

perform as they are intended. These points can be causes of weighing problems. The zero

facility is provided to reset the zero although this should not normally be necessary.

➢A firm, level floor surface is required

➢Do not move the press around the floor during a bale as this will upset the zero

reference point. If moving is necessary, wait until that bale is completed.

➢Begin and end the bales with the press in the same condition i.e. if the scale is on zero

and the press is ready to operate, (Door and hungry board closed, platen up etc.), the

scale will not zero until the press is in the same condition.

➢Check that there is not a build up of wool around the base of the press as this will

restrict free movement.

➢Check that the two bolts mounting the load cell are tight.

➢Check that the press is level and lock nut on the load cell foot is tight.

➢During operation the jockey wheel must be secured by the catch. The jockey wheel

brake foot must be clear of the floor. If not it will effect the scale operation causing

bale weights to be inaccurate.

➢When moving the woolpress it is important that it has come to a complete stop before

lowering the weight of the woolpress onto the loadcell foot, otherwise damage may

occur to the loadcell and foot.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

13

12 Woolpress maintenance

12.1 Safety guard maintenance

The press is fitted with an interlocked safety device and guards to protect the operator

during use. These must be maintained for safe/correct operation.

Before each shift starts the following parts must be checked for correct operation.

Safety guard

Valve handle

Safety guard arms

Hungry board interlock assembly

Safety guard linkage

Gas lifting strut

Pinning guards

Valve linkage

These parts are integral to the safe operating of the press. If they become damaged, worn

or loose they must be repaired or replaced before using the press.

When replacing parts use only genuine replacements or parts that have the same

specification.

The following checks must be carried out:

Note: Turn the power off and leave it off while checking the operation of the safety device.

1. With the safety guard open ensure that the valve handle cannot be pulled into the

down position. If it can, repair or adjust before using the press.

2. Close the safety guard, pull the valve handle into the down position. Slowly lift the

guard open. The valve handle should be knocked into neutral or the up position within

approximately 25mm (1”) of upward movement of the safety guard. If it does not,

repair or adjust before using the press.

3. Open the hungry board, close the pack lock and the safety guard. Attempt to pull the

valve handle into the down position. The valve handle should not be able to move into

the down position. If it can, repair or adjust before using the press.

4. Check the security of the pinning guards, the pinning guards are routinely removed for

maintenance. They must be replaced securely before the press is used.

12.2 General maintenance

Ensure the motor is switched off and the power disconnected while performing

maintenance.

Always contact an authorized service centre if you are unsure how to rectify problems and

in the event of a malfunction not contained in this manual.

Maintenance instructions listed here are guide lines only, because of differing conditions

that presses experience it is impossible to say what maintenance a press will need and

when.

Note: If any parts are replaced on the press, use genuine replacement parts or ensure

that replacement parts have the same specification as the old parts.

12.3 Daily maintenance. (8 to 10 hrs of operation)

➢Grease/oil the locking bar, rotate and lift the locking bar for better access. Use a good

quality general purpose grease and good quality engine oil.

➢Check correct operation and adjustment of safety device.

➢Check the security of the platen retaining bolt that secures the platen to the cylinder

rod.

Note: If the press is allowed to operate with this bolt not properly secured the hydraulic

circuit will be placed under undue stress that will prematurely wear components.

12.4 Monthly maintenance. (200 hrs of operation)

➢Grease both guiderods and grease/oil all moving parts.

➢Check the accuracy of the scales. Check the weight of the most recently pressed bale

on scales known to be accurate.

➢Check the security of the cylinder retaining nuts and platen retaining bolt.

➢Check the security of all other fasteners. Some fasteners secure hinging parts, do not

over tighten these fasteners. Hinging parts need to move freely through the range of

movement without being loose.

➢Check the hydraulic oil level and replenish as necessary. Use specified oil.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

14

➢The hydraulic oil level is checked with the platen in the up position. To check, remove

the filler/breather cap on the tank. The oil should be approximately 100mm from the

top +/- 25mm.

➢Oil the bellcrank assembly and baling pin bosses, remove the pinning guard to do so.

Apply oil to all moving joints, wipe off excess. The bellcranks can be moved in and out

by hand.

➢Check the security of the circlips retaining all pins.

➢Check the adjustment of the baling pins.

➢Clear any wool from inside the pinning guards.

Note: Failure to perform reasonable maintenance on the press will result in premature

wear or damage to the press. This wear or damage is not covered by the manufacturer’s

warranty.

12.5 Oil change

Change the oil every 12000 hours of operation. This is an approximate figure. If the oil is

contaminated by water or foreign matter, or has been overheated then the oil will need

changing more frequently.

12.6 Filter change

Change the oil filter and tank filler/breather cap every 2000 hours of operation. This is an

approximate figure. If the press is operating in a very dusty or humid environment the

filters will need changing more frequently.

Note: If any parts are replaced on the press, use genuine replacement parts or ensure

that replacement parts have the same specification as the old parts.

12.7 Pressure relief valve

Situated on the control valve (see illustration). The pressure in this valve is factory set to

18,000 KpA(2600 psi) and should NOT be adjusted. Occasionally, this valve may be heard

to squeal when the press has returned to neutral. This is caused by the spool not

centralising, either through the detent on the bottom of the spool becoming loose, or the

valve trip lever not operating correctly.

Control valve illustration

Spool

Top of

cylinder

Return

Bottom of

cylinder

Dome nut

Relief

Detent cover

Spring

tensioner

Lock nut

Spring

Valve

needle

Detent

Spring

Valve

OILPATH

IN

R

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

15

12.8 Control valve neutral adjustment

Due to normal running in of new components it is sometimes necessary to adjust the

control valve neutral rod, to ensure that the control valve will automatically return to

neutral at the completion of its cycle.

Adjustment

Should the valve not drop into neutral, tap the control valve neutral rod to the right or left

until correct action is achieved. Several cycles of the press may be required for this setting.

If the adjustment is moved too far to the left (rear view), or too close to the pivot bolt, the

valve may push too far and go over 'centre' and cause the ram to re-cycle automatically.

This adjustment may require setting from time to time as the press settles in.

Control valve neutral adjustment illustration

12.9 Baling pin adjustment

When the guide rods are at the maximum down position, the pins are correctly set if there

is approximately 1mm of backlash.

To set the Baling pins:

Note: If the left hand bank of pins has less backlash than the right hand it is advisable to

back off (wind up) the adjustment bolt on the top of the left hand guide rod before

proceeding.

1. Send the platen on the down stroke and allow the pins to go in. Carefully watch for

the point when the control valve lever is about to be actuated into the up position and

stop the lever in the "natural" neutral position, with your hand held above the control

lever.

2. Check the backlash between the bellcranks and the bin, and if incorrect, adjust the

return bolt on top of the right hand guide rod carefully ½ a turn at a time, (up to

decrease clearance or down to increase clearance).

3. Repeat the cycle until the correct backlash is achieved.

4. Tighten locknut securely.

5. After setting right bank of pins, repeat procedure for left hand bank of pins using

adjustment bolt on left hand guide rod. Ensure the hexagonal sides of the bolt are

kept parallel with the side of the guide rod when adjustment is complete.

Note: Take care to adjust small amounts then cycle the press each time to prevent over-

adjustment and possible damage to guide rods.

Control valve neutral rod

L/H

R/H

Rocker arm

Rear ejection handle

Viewfrom rear of press

Pinning adjustment

Return bolt

1mm Clearance

Bellcrank

adjustment

Pinning Bin

Platen

Trip Lever

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

16

12.10 Unpinning clearance

The retraction of the baling pins is a crucial part of the press's operation. The pins are

retracted by the unpinning posts, which are welded to the platen, pulling down on the

rocker arm pawls, which are in between the top cross members.

To enable the baling pins to be fully retracted from the wool, the posts must remain in

contact with the pawls until the baling pins are fully retracted.

This length of contact or "travelling purchase" can only be achieved by having the gap

between both components as close as possible once they have separated.

No less than 0mm and no more than 2mm.

If this gap is too excessive due to wear on the pawls or distortion of the platen, the

unpinning posts will lose contact with the pawls prematurely, leaving the baling pins

partially in the bin while the wool is being pressed, possibly resulting in damage to the press

or woolpack.

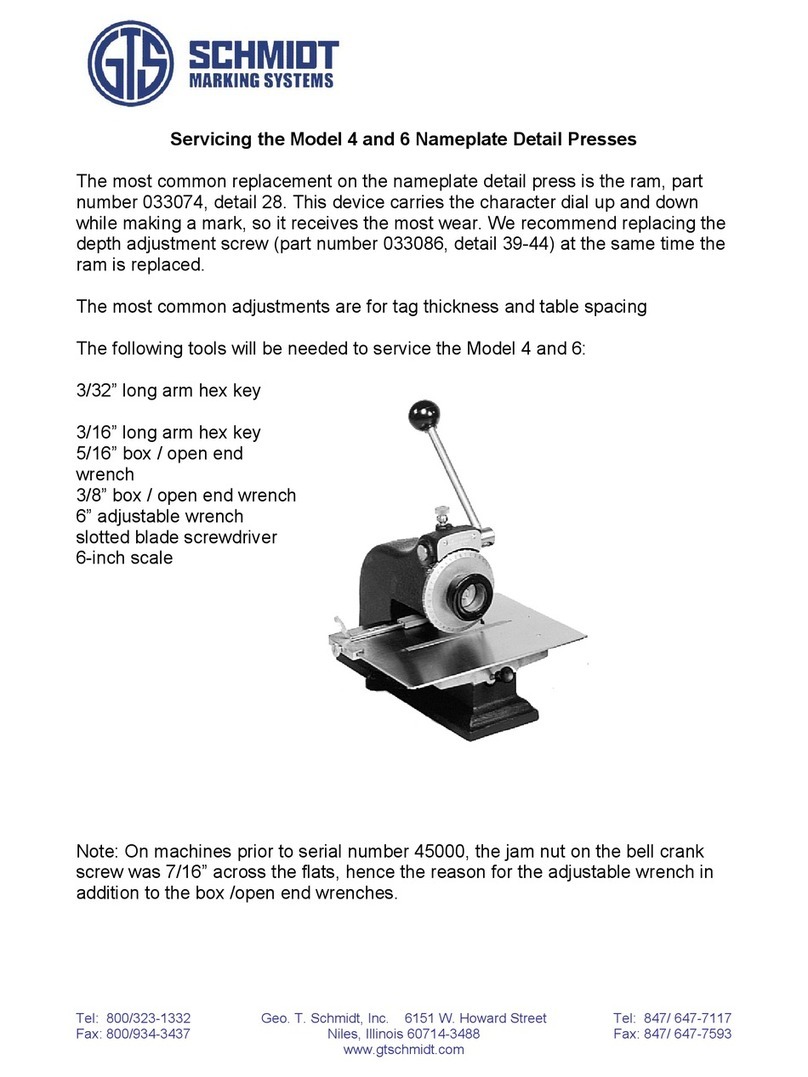

Unpinning clearance illustration

12.11 Hydraulic pump operation

The Nachi PVS-IB-22 Pump is a variable displacement piston pump with a pressure

compensator valve.

The pump produces a flow of 30 lts/min (7 gpm) until pressure builds to 5000 KpA (750

psi).

This opens the pressure compensator valve and reduces the flow to approximately 7-

9Its/min (1.5-2.0 gpm, second stage)

When the changeover to the second stage happens, you should notice a change in sound

and speed, and a reduction in load on the motor.

The compensator valve adjustment controls the pressure at which the changeover cycle

takes place. 5000 kpa (750psi)

Before adjusting any settings it is advisable to measure and note the standout

distance of the screw. Screw adjustments in to increase, out to decrease.

Cylinder Rod

Rocker arm

post

Unpinning

rod

Push

Platen

Pawl

Guide rod

0mm

+ 2mm

-0mm

clearance

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

17

12.12 Pump adjustment procedure

1. Low pressure adjustment screw (compensator valve). This controls the pump

changeover from 1st to 2nd stage. (Approximately 140 to 150 kilos of wool), It also governs

how fast the platen returns. Voltage drop may be experienced in some sheds. This may

cause the motor to labour around the changeover stage or on the return stroke. A small

adjustment of the Low Pressure screw will cure both problems in most cases.

2. High pressure adjustment lock nuts (minimum stop) the positioning of this setting

determines the flow once the press is in the second stage.

Adjustments of the lock nuts clockwise will increase the flow rate but also increases the

power demand.

Anti clockwise will decrease the flow rate.

This adjustment is only needed if the press is stalling or labouring in the second stage but

rarely has to be reset and should be done with a flow meter and tong tester.

Hydraulic pump adjustment illustration

High pressure

adjustment

nuts

Spring group with

dust cover removed

Lock nut

Low pressure

(for changing to second stage)

adustment screw

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

18

13 Troubleshooting All items marked * see adjustment procedure

Note: For all electrical faults qualified persons only may undertake fault finding & repairs.

Note: For all hydraulic faults qualified persons only should undertake fault finding & repairs.

Problem

Possible cause

Action

The motor will not

Fuses blown

Check reason and replace.

start

Faulty plug

Replace

Start capacitor is

burnt out

Replace

Supply voltage is too low

Correct supply

Starter switch chatters

Supply voltage is too low

Correct supply.

and will not engage

Extension cord is too long or

too light

20 Amp extension cord.

Overload not set

Leave for one minute then press

red stop button to reset

Faulty switch

Contact Electrician

Motor stalls

Overload

Check power supply

Second stage on pump

Check low pressure adjustment

not activated

( compensator) on pump* Page

17

Second stage flow

Adjust high pressure ( minimum

stop)

capacity too high

adjustment* Page 17

Pressure relief valve set too

high

Reset pressure relief valve

Coupling loose

Tighten or replace

Pump seized

Replace pump

Press will not operate

No oil flow

Check operation of electric motor,

pump, control valve, coupling,

ram and oil level

3 phase motor running in

reverse

Electrician to reverse phases to

suit.

Pump noise

Cavitation

Check oil level

(air in system)

Check suction hose

Check oil filter damaged, loose or

clogged

Loose coupling

Check for damage, wear,

alignment and secure key

and grub screws

Faulty pump

Replace

Control valve noisy

Relief valve incorrect

Check for damage and reset

pressure relief valve

Spool valve travel

Check detent

incorrect

Check handle for damage

Valve not neutralising

Adjust Check linkage is not bent.

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

19

Press is too slow

Loose detent on valve

Remove dust cover on bottom of

valve spool and tighten detent

Note: do not dismantle the detent

Pump worn out

Replace pump

(Check with flowmeter)

High pressure

Re-adjust* Page 17

adjustment (minimum

stop) screwed out

Seals worn or damaged

Replace or repair

on ram piston

Motor labours once cycle is

complete

Control valve return bolt

setting incorrect

Reset as per instructions* Page

11

Control valve handle

vibrates once cycle is

completed

As above

As above

Cannot press

Pressure relief set

Check using pressure gauge and

heavy weights

below 2600 psi

reset

Pump not coming in on

Check low pressure adjustment*

Page 17

second stage

Seals worn or damaged

Replace or repair

on ram piston

Voltage supply too low

Check your local supply current.

overloads should cut out

Baling pins bent down

Press cycle not completed

Replace bale pins. Operate as

per instructions

Clearance between

Check for wear or misalignment

pawls and unpinning

Repair or replace and adjust as

post excessive

per diagram* Page 12

Baling pins will not

Pins bent (as above)

Replace pins

hold bale

Baling pins do not go

Guide rods out of

Adjust correctly* Page 11

in fully

adjustment

Baling pins will not

Clearance between

Check for wear or misalignment

fully retract

pawls and unpinning

Repair or replace and adjust as

post excessive

per diagram* Page 12

Build up of wool

Remove pinning guard and

around bellcrank

remove wool

MA005 TPW Woolpress Operator Manual 2019-06-06

Rev:05

20

14 General layout illustration

This manual suits for next models

1

Table of contents

Other Heiniger Power Tools manuals