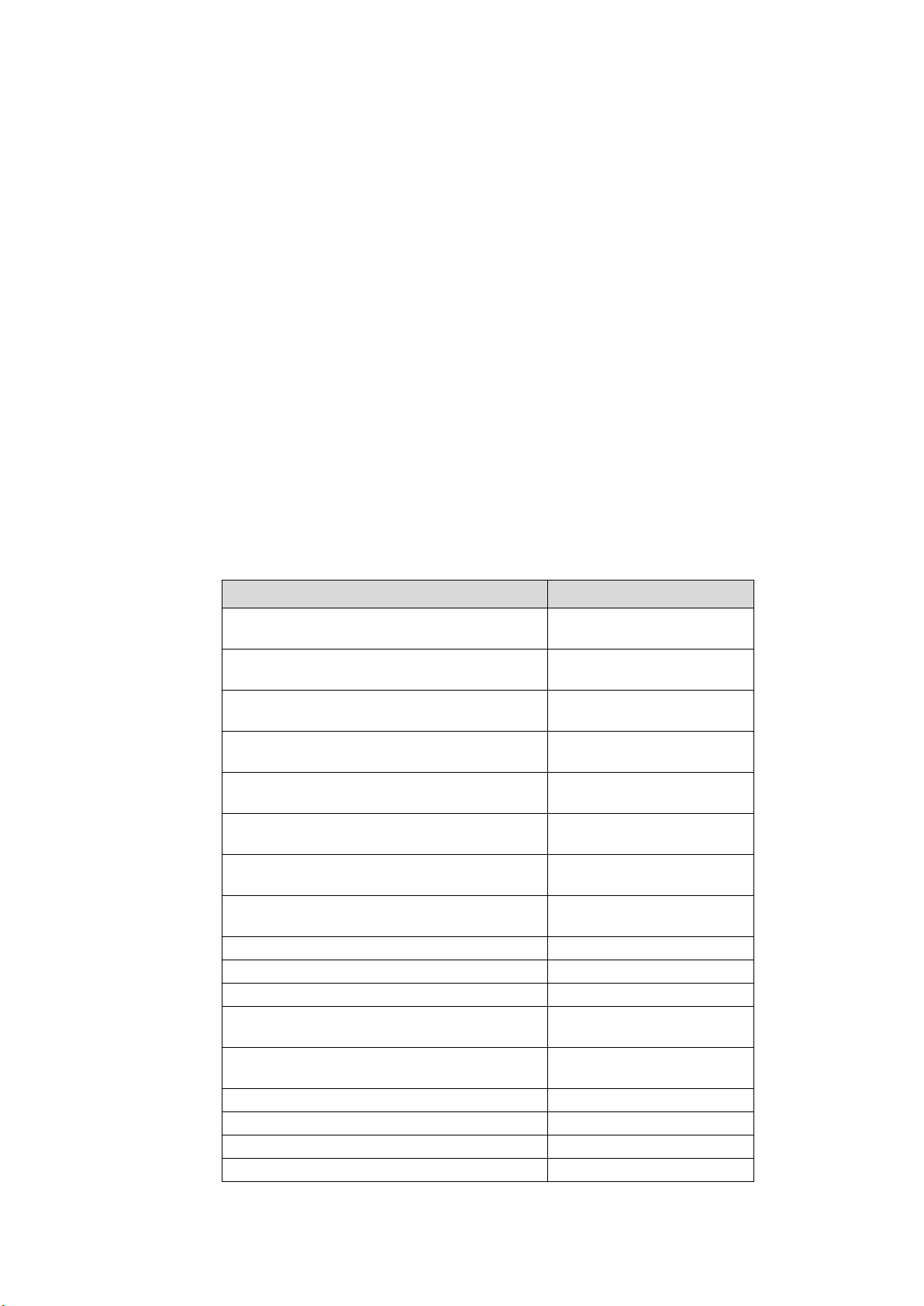

Section Description Page No.

1. INTRODUCTION ........................................................................................................5

1.1 SAFETY INSTRUCTIONS.............................................................................5

1.2 DESCRIPTION OF THE LIGHT FIXTURE....................................................6

1.2.1 Dimensions of the Fixture......................................................................6

1.2.2 Selection of Isolation Transformer .......................................................8

1.2.3 Transformer Selection Guidelines ........................................................9

1.3 DELIVERY OF THE LIGHT FIXTURE.........................................................11

2. INSTALLATION........................................................................................................12

2.1 TYPICAL INSTALLATION ...........................................................................12

2.2 ANGLE ADJUSTMENT................................................................................15

2.2.1 Azimuth angle .......................................................................................15

2.2.2 Altitude angle ........................................................................................15

2.3 LIGHT EMISSION DIRECTIONS.................................................................15

2.3.1 Definition of Light Emission Directions .............................................15

2.3.2 SafeLED IQ0 and SafeLED IQ1 Schematic Installation Example .....17

2.4 TOOLS REQUIRED.....................................................................................17

3. INSTALL/REMOVE ON/FROM A SUPPORT..........................................................18

3.1 SET THE LIGHT FIXTURE..........................................................................19

3.2SIGHT DEVICE FOR SL-E-B LIGHT FIXTURE ..........................................20

3.2.1 Mounting the Sight Device...................................................................21

3.2.2 Toe-in Adjustment Operation ..............................................................23

3.2.3 Manual Adjustment Operation.............................................................24

3.2.4 Using the Sight Device.........................................................................25

4. OPERATION.............................................................................................................27

4.1 TECHNOLOGY DESCRIPTION..................................................................27

4.1.1 ASP Safecontrol System Technology.................................................27

4.1.2 SafeLED IQ and the 2A concept..........................................................27

4.1.3 Sensor Interface Unit (SIU) ..................................................................27

4.1.4 Network Concentrator Unit (NCU).......................................................27

4.1.5 Series Circuit Modem (SCM)................................................................27

4.1.6 Series Circuit Filter (SCF) ....................................................................27

4.1.7 Control System Interface .....................................................................28

4.2 PROGRAMMING SAFELED IQ...................................................................28

4.2.1 Setting up the Hardware Equipment...................................................28

4.2.2 Programming the Software..................................................................30

4.3 CONNECTING THE LIGHT FIXTURES IN A SERIES CIRCUIT................33

4.3.1 Operational Characteristics.................................................................33