!The HIGH alarm is always latched due to code requirements. DIP switch

positions 1, 2 and 3 are set at the factory - DO NOT change setting! If you

suspectthatsettingshavebeenchanged,resetperinstructions onpage 911-7.

DESCRIPTION

The SST Model GIR911 Infrared Carbon Dioxide Gas NOVA-Sensor is a completely

self-contained device that measures and displays the concentration of gas accumulated

in a protected area, performs local control functions, and transmits this information to a

central control point.

Principle of Operation

The GIR911 uses the absorption of carbon dioxide at 4.25 µm for the detection of CO2.

The GIR911 contains an incandescent lamp pulsed at 4 Hz in conjunction with two

piezoelectric light sensors all contained in a plug-in housing ("optical bench"). In a

patented configuration, the sensors are close to each other and are exposed to the direct

light from the lamp, with no mirrors or other optical structures involved. In addition, almost

no light is reflected by the walls of the bench thus eliminating all possible influences from

wall contamination. The active sensor has an optical filter tuned to 4.25 µm; the reference

sensor sees the wide-band infrared signal from the lamp.

The presence of carbon dioxide will decrease the signal to the active sensorsignificantly,

while the signal to the reference sensor is almost unchanged. The electronics module

contained in the GIR911 constantly measures the signals from both sensors, averages

them to filter out noise and then calculates the ratio of the averaged active and reference

signals. With a constant length of the optical axis, the relation between the A/R ratio and

the actual gas concentration is logarithmic. The length of the optical path yields an output

for hydrocarbons that allows measurements with a resolution of 1%-2% of reading. The

ratiometric principle makes it possible to eliminate almost all effects of temperature,

aging, or fogging that would otherwise spoil the measurement. The optical operation

principle has the following advantages:

• Readings independent of Oxygen, wind, etc.

• Readings NOT influenced by cross-sensitivity and poisoning

• No burn-out, saturation, shift or drift when the detector is exposed to high gas

concentrations

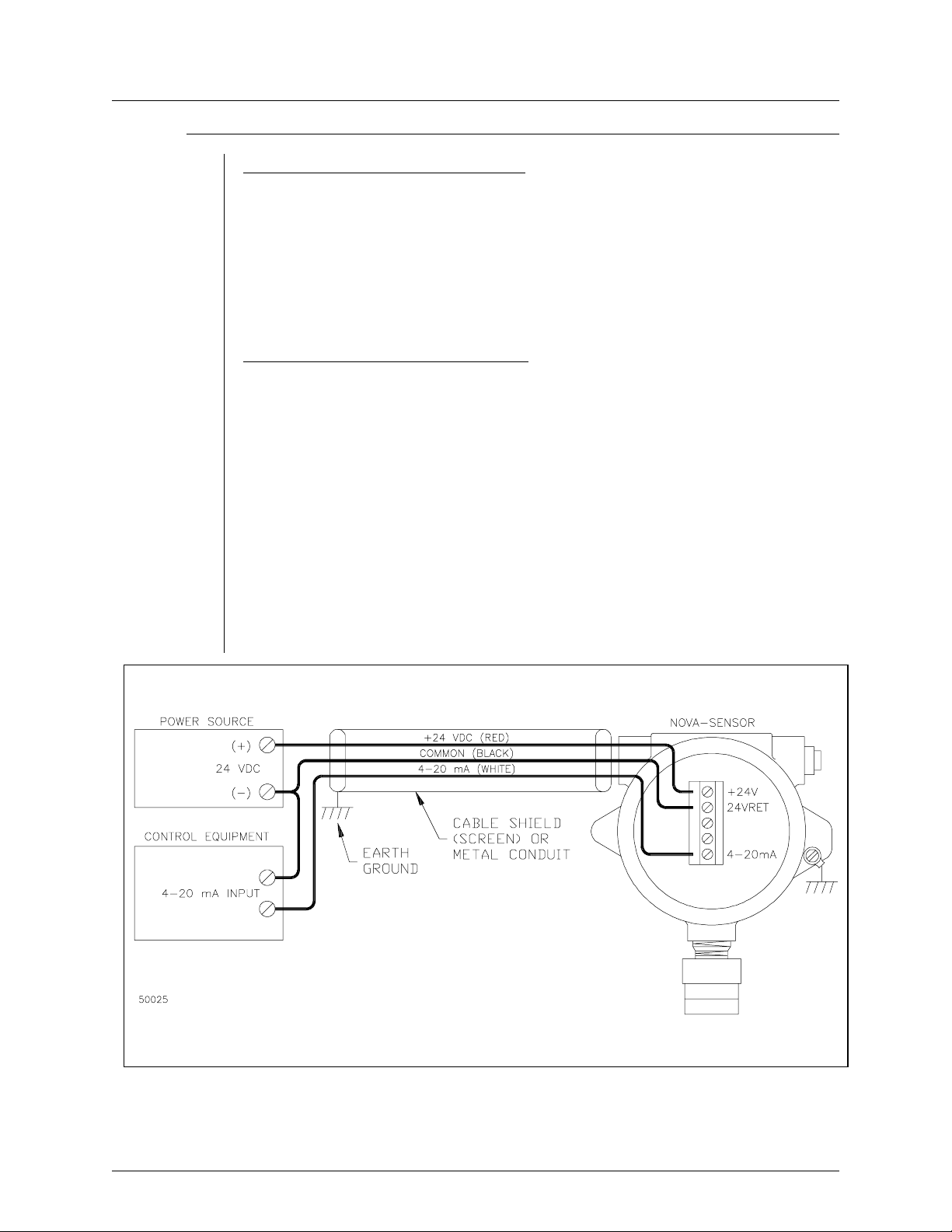

Each SST NOVA-Sensor includes a high reliability microcontroller based transmitter/con-

troller in the associated explosion proof junction box. A digital read-out is provided to

continuously display operating status and the actual concentration of gas present in

percentage by volume. The transmitter converts this reading to a standard 4-20 mA

signal. This signal may be connected to a suitable SST NOVA-5000 Gas Detection

Module, or to any other device with a standard 4-20 mA input. Connections between the

transmitter and control device are normally made with 3 conductor cable [+24 VDC, 24

V return, 4-20 mA signal]. Dry contact relay outputs are provided for the LOW alarm,

HIGH alarm, and fault. The LOW and HIGH relays operate at user adjustable alarm

setpoints; the fault relay operates upon loss of power or internal failure of the unit. Relays

are suitable for controlling local HVAC or equipment shutdown.

MODEL GIR911 INFRARED CARBON DIOXIDE GAS NOVA-SENSOR

911-2 December, 2003 911-2