TECHNICAL NOTE

Safran Colibrys SA 30N.EVBA V2.10.16

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 7 F +41 58 100 5001

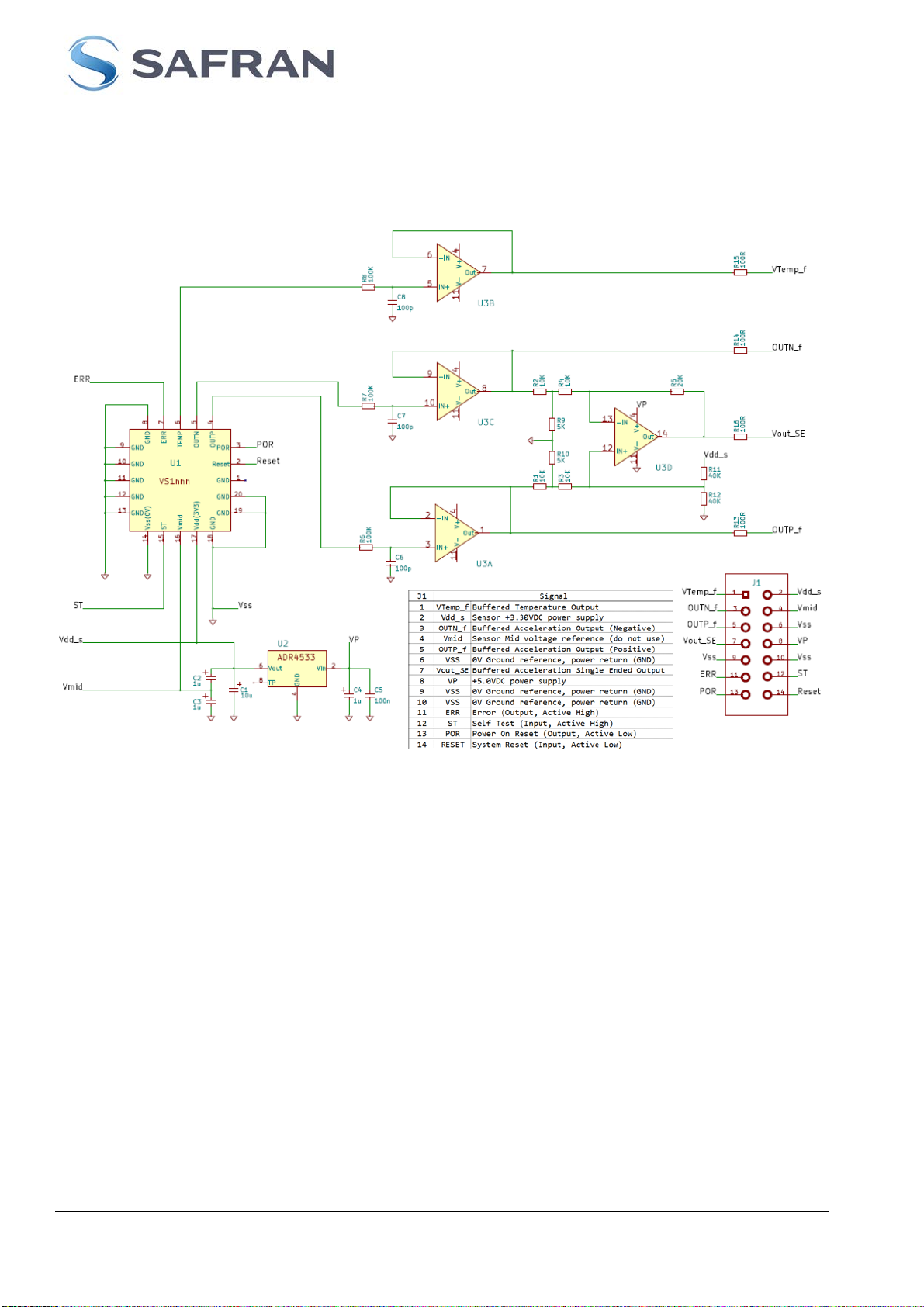

2.10 Bill of material (BOM)

The following table lists all components used for the presented design:

Component Value Function

U1 VS1000 Safran Colibrys Accelerometer

U2 ADR4533 3V3 Voltage Reference – Analog Devices ADR4533BRZ

U3 AD8574 Quad Operational Amplifier – Analog Devices AD8574ARZ

R1, R2, R3, R4 10 kΩ Voltage divider – 0402 resistor

R5 20 kΩ Voltage divider – 0402 resistor

R6, R7, R8 100 kΩ Low pass filter – 0402 resistor

R9, R10 5 kΩ Voltage divider – 0402 resistor

R11, R12 40 kΩ Voltage divider – 0603 resistor

R13, R14, R15, R16 100 Ω Output load – 0402 resistor

C1 10 µF Decoupling – 0603 capacitor

C2, C3, C4 1 µF Decoupling – 0402 capacitor

C5 100 nF Decoupling – 0402 capacitor

C6, C7, C8 100 pF Low pass filter – 0402 capacitor

J1 HEADER 7X2 Connector (if required*)

*The wires may also be soldered directly on the board.

Table 2: Bill of material

3 Operation

Handle with appropriate precautions and be done in accordance with strict ESD control.

It is the user choice to use the connector provided or to solder the signal wire lines

directly on the board. In both situation please follow the proper soldering process. Hand

soldering is recommended.

3.1 Power Up

Once the cabling done the EVBA can be powered up by applying the VP voltage level. The current consumption

and the reference voltage VDD shall be:

Parameter Designation [unit] Typical

Sensor +3.30V power supply VDD [VDC] 3.30

Board current consumption IP [mADC] 7.14