mRO Series Evaluation Kit Manual, Rev 1

Page 5of 16

To record data coming from the mRO, select the filename path, and check the Record box.

Data record

All data parameters coming from the mRO can be recorded inside a dedicated “record file”

according to the timegate. The software records 27 parameters:

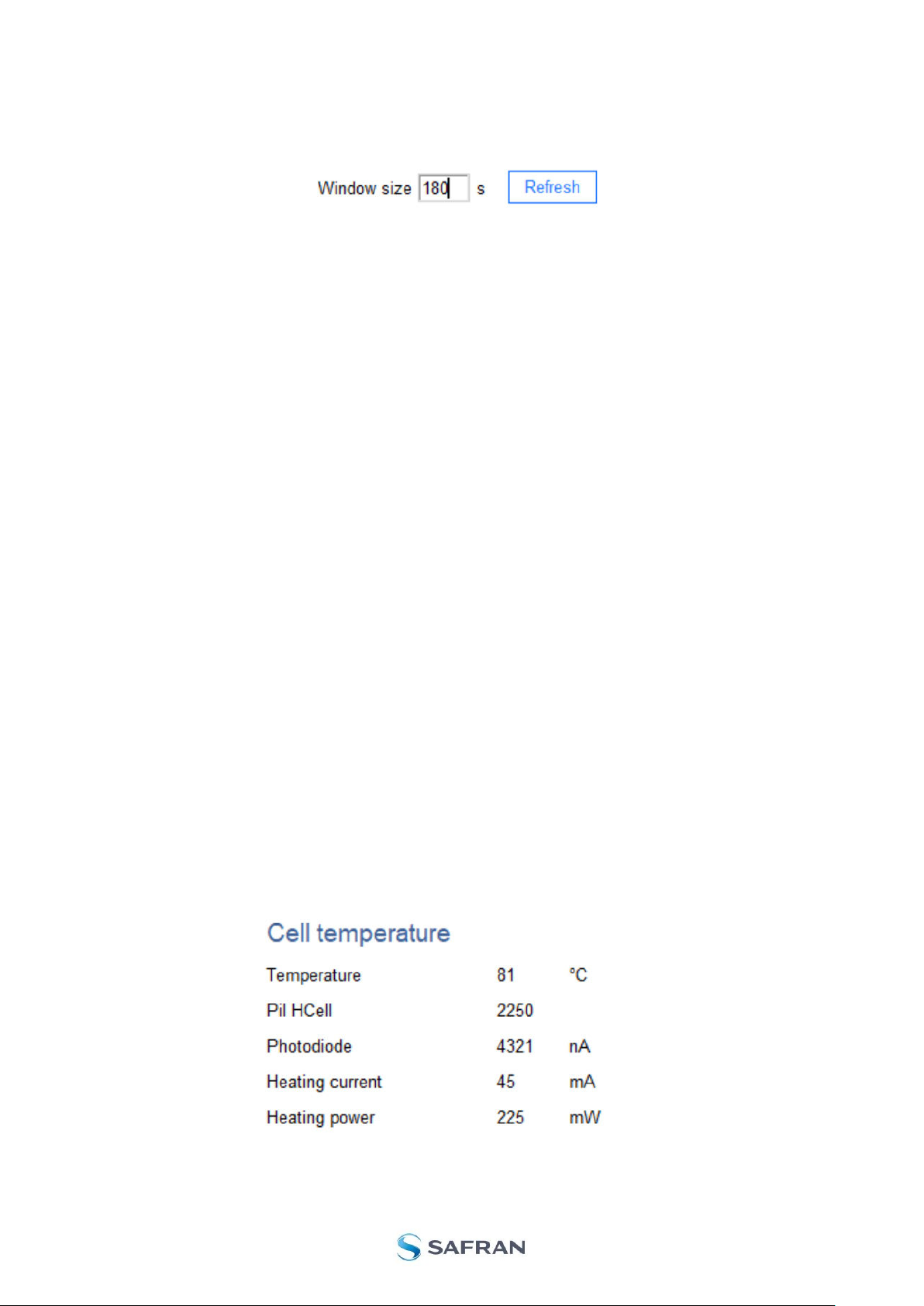

1. Unix_Timestamp: System (PC) time in seconds

2. IPhot(int): Photodiode data measured by the mRO, this is an int value

3. Atomic_SIGNAL_MIDDLE_RANGE (int) Satom 15: signal level data on the first side of the

Rubidium line

4. Atomic_SIGNAL_UPPER_RANGE (int) Satom 31: signal level data on the second side of the

Rubidium line

5. Heating_Power_Laser (int): heating power dissipated in order to warm the laser diode

6. Heating_Power_Rb_cell (int): heating power dissipated in order to warm the Rb cell.

7. Laser_source (int): voltage supply of the unit powering the laser diode of the mRO

8. Laser_Voltage (int): laser voltage, measured by the mRO

9. MiniRb_Temperature (int): temperature signal of the mRO

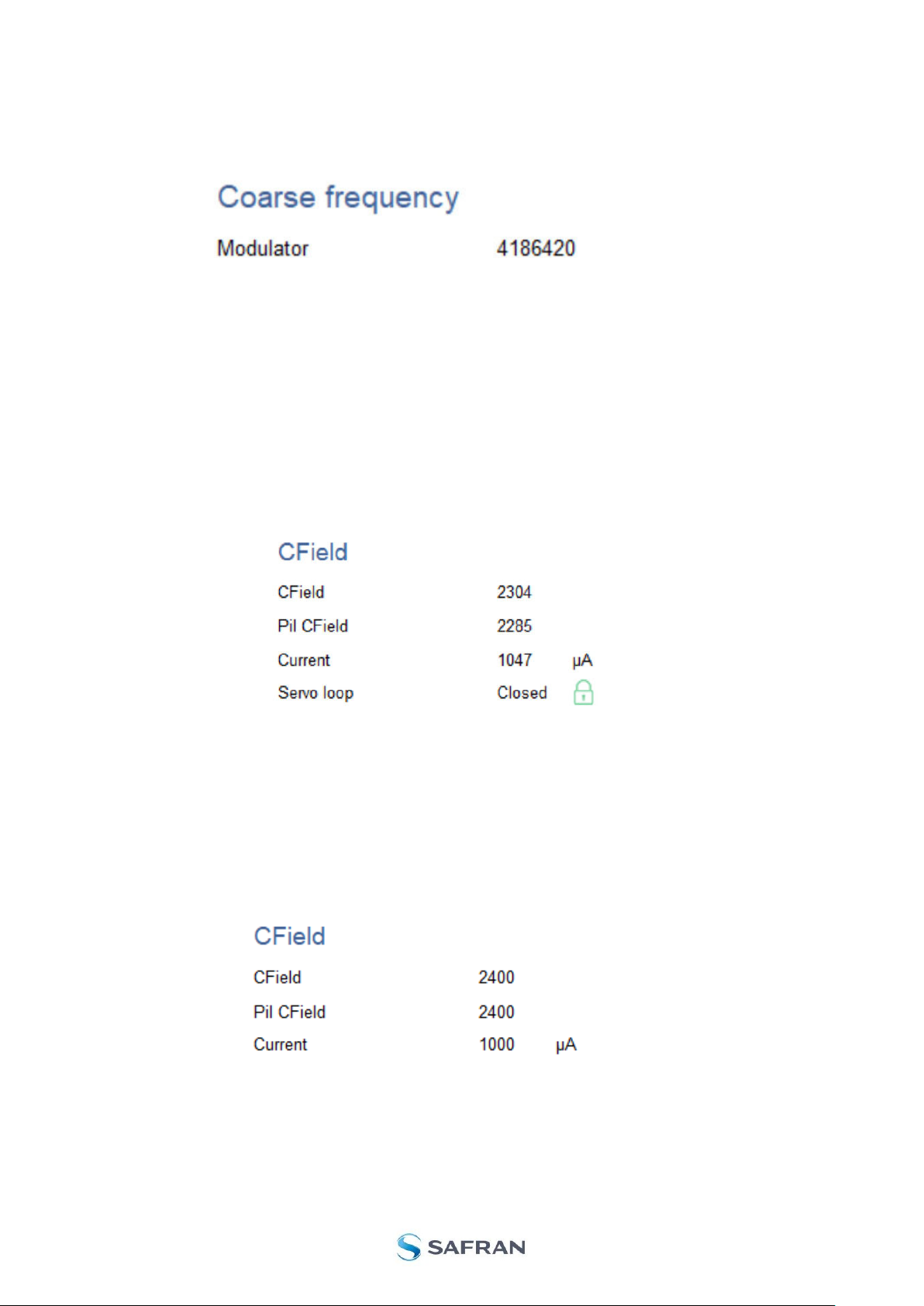

10. Voltage_control_TCXO (int): DAC value connected to the 10 MHz TCXO voltage control

input

11. CFIELD (micro-Amp): current flowing through the magnetic coil in micro-Amp

12. Temperature cell setting (int): temperature setting point of the Rb Cell

13. Temperature laser setting (int): temperature setting point of the laser

14. Pil Laser (int): polarization of the power amplifier which drive the laser

15. PIL_CFIELD (int): polarization of the power stage which drive the current flowing through

the magnetic coil

16. PIL Polar AOP (int): pre-polarization of the power stage which drive the laser

17. PIL VC: TCXO voltage control input

18. Status: mRO status

19. Rb_cell_temperature_setting point (°C): temperature of the rubidium cell

20. Laser_temperature_setting point (°C): temperature of the laser

21. MiniRb_Temperature (°C): temperature of the mRO

22. Laser_current (micro-Amp): current flowing through the laser diode.

23. Photodiode current (nano-Amp): current flowing through the photodiode.

24. Heating_Power_Rb_cell (mWatt): heating power dissipated to warm the Rubidium cell

25. Heating_Power_Laser (mWatt): heating power dissipated in order to warm the Laser

26. Cell heating current (mA): Current in milliAmp flowing through the heating system of the

Rb cell

27. Laser heating current (mA): Current in milliAmp flowing through the laser heating system.