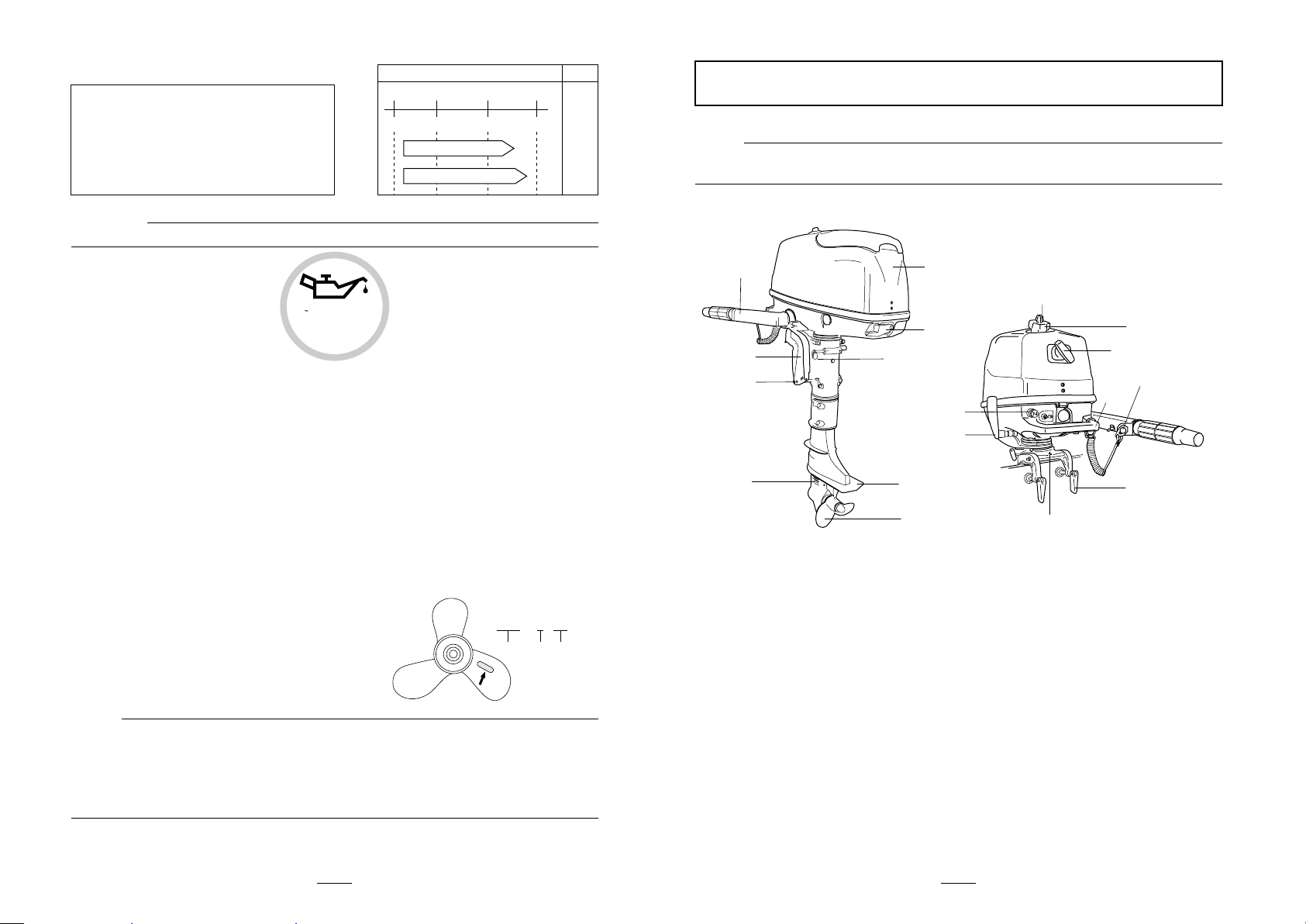

12 13

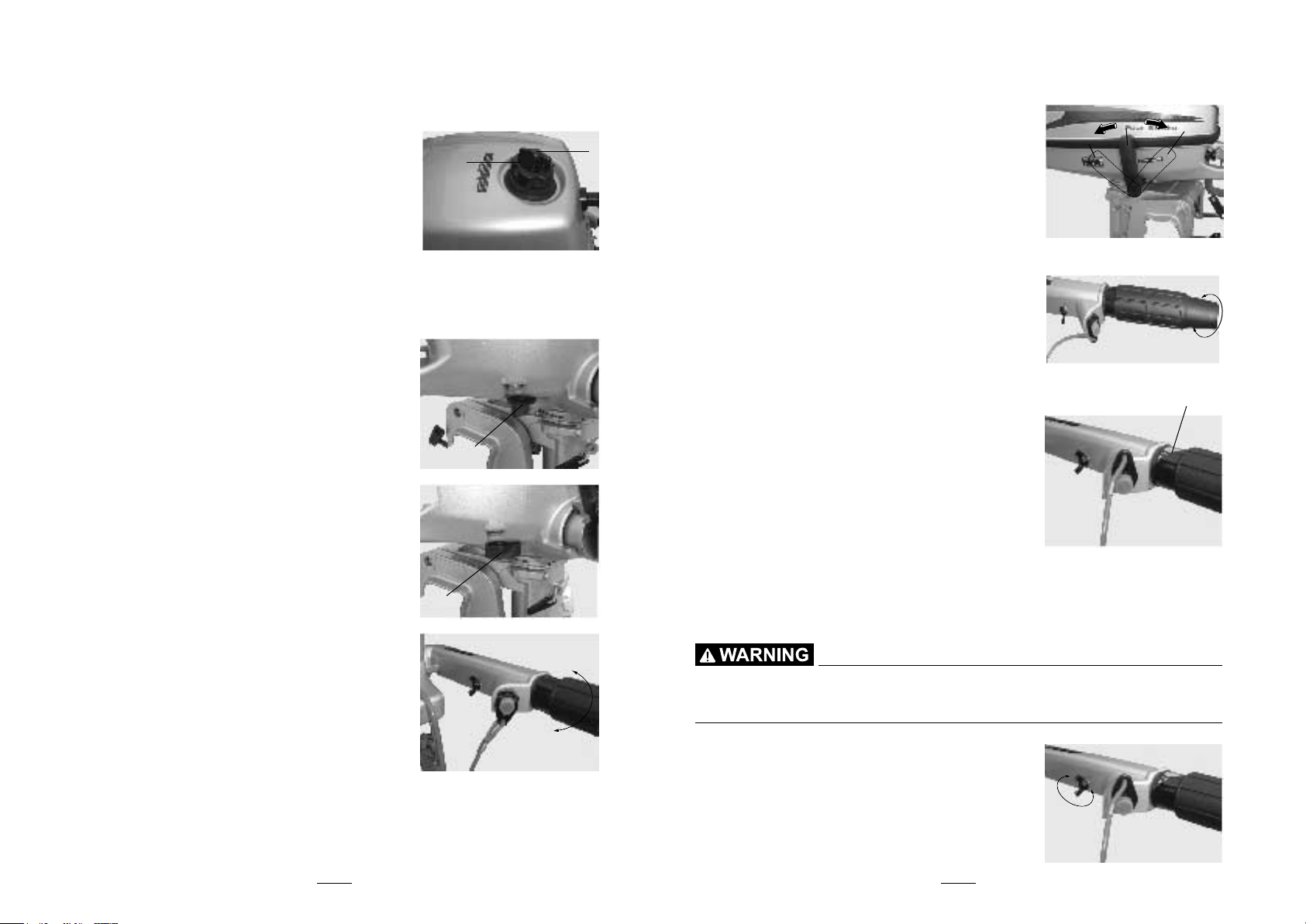

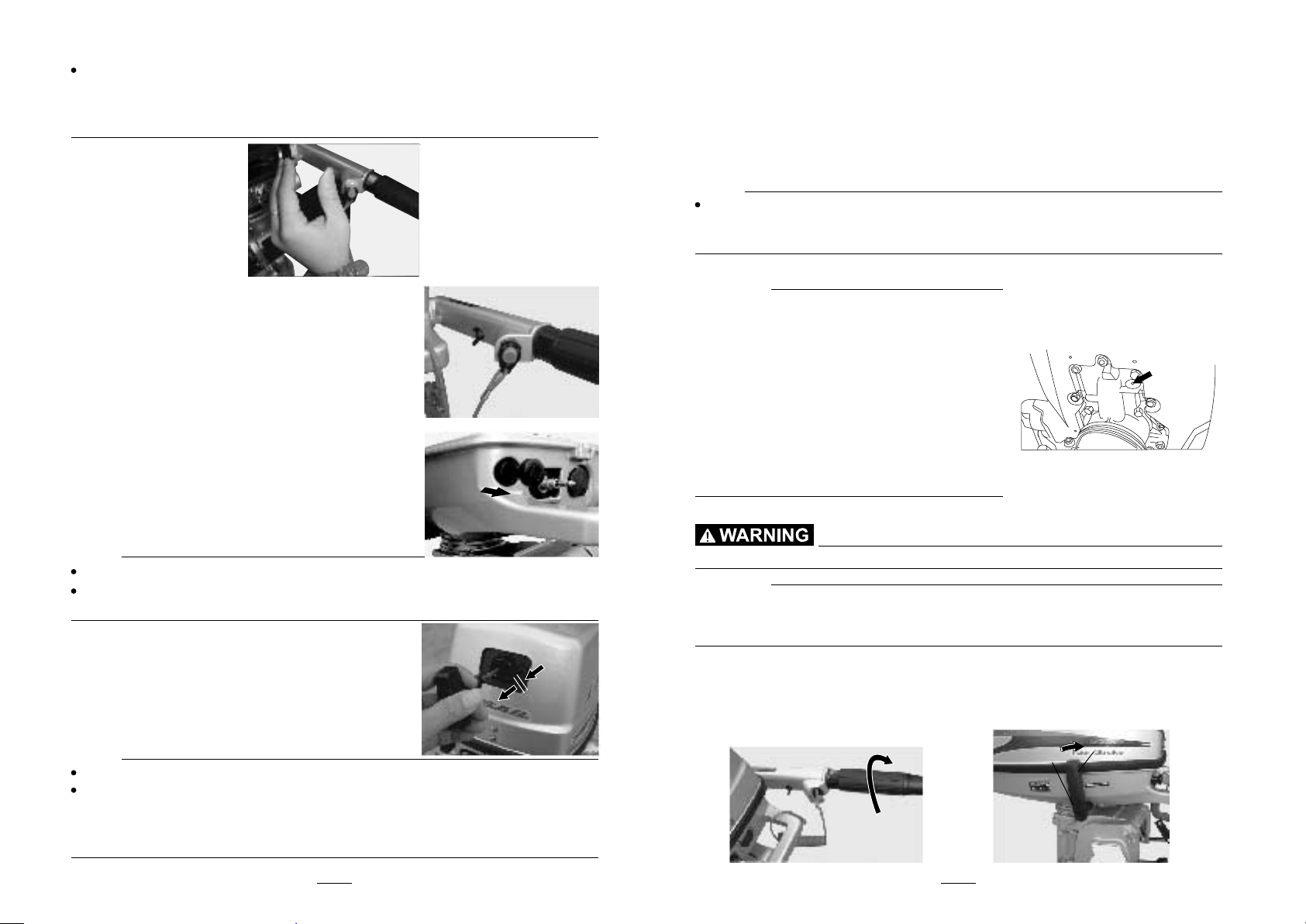

and outboard motor must be made as little as possible. The mounting height of the

outboard motor greatly affects the water resistance. If the mounting height is too hi-

gh, cavitation tends to occur, thus reducing the propulsion; and if the propeller tips

cut the air, the engine speed will rise abnormally and cause the engine to overheat.

If the mounting height is too low, the water resistance will indrease and thereby red-

uce engine efficiency. Mount the outboard motor so that the anti-cavitation plate is

between the bottom of the boat and a level 25mm (1 in.) below it.

NOTE:

The optimum mounting height of the outboard motor is affected by the boat and

motor combination and the desire use. Test runs at different heights can help d-

etermine the optimum mounting hieght. Consult your dealer or boat manufactu-

rer for further information on determining the proper mounting height.

For instructions on setting the trim angle of the outboard motor, see page 18.

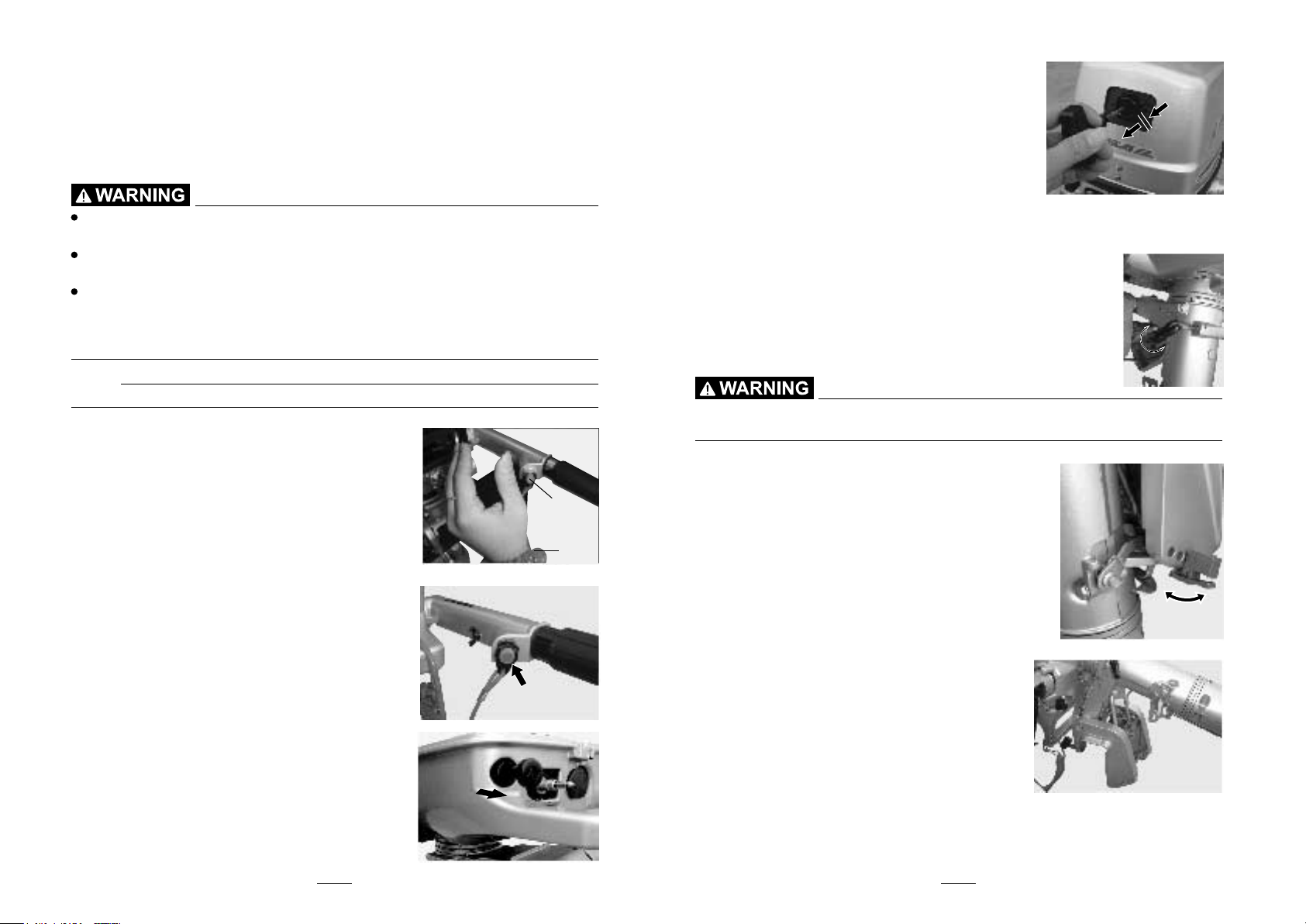

Clamping the outboard motor

1.Place the outboard motor on the transom so that it is positioned as close to

the center as possible. Tighten the transom clamp screws evenly and

securely. Occasionally check the clamp serews for tightness during

operation of the outboard motor because they could become loose due to

engine vibration.

Loose clamp screws could allow the outbo-

ard motor to fall off or move on

the transom.

This could cause loss of control and serious

injury. Make sure the transom screws are tig-

htened securely. Occasionally check the scr-

ews for tightness during operation.

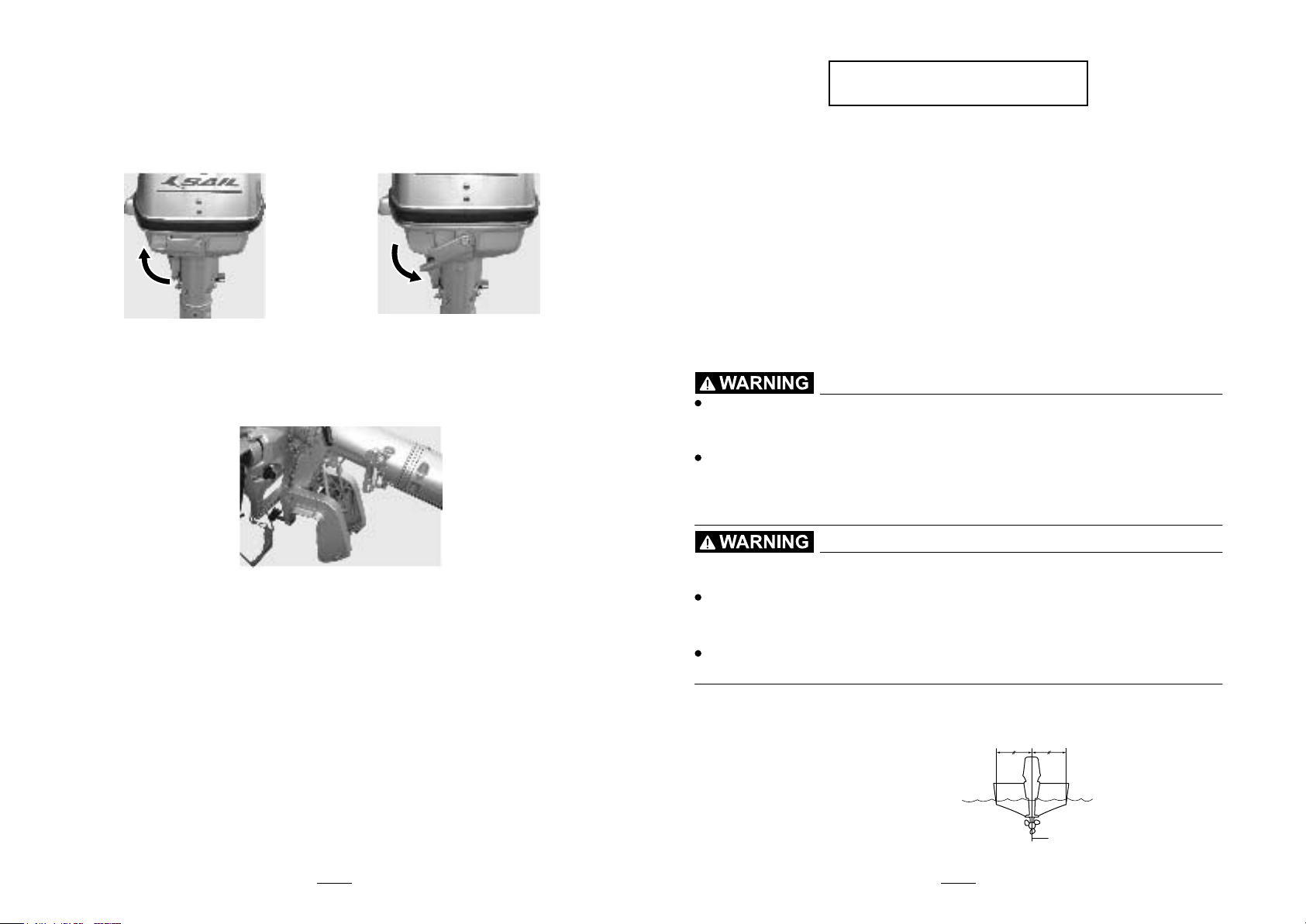

2.If the engine restraint cable attachment is

equipped on your engine, an engine restraint

cable or chain should be used. Attach one e-

nd to the engine restraint cable attachment a-

nd the other to a secure mounting point on

the boat. Otherwise the engine could be com-

pletely lost if it accidentally falls off the transom.

3.Secure the clamp bracket to the transom using the bolts provided with the

outboard (if packed). For details, consult your dealer.

Avoid using bolts, nuts or washers other than those contained in the

engine packaging. If used, they must be of at least the same quality of

material and strength and must be tightened securely. After tightening,

test run the engine and check their tightness.

Breaking in engine

Your new engine requires a period of break-in to allow mating surfaces of

moving parts to wear in evenly. Correct break-in will help ensure proper

performance and longer engine life.

CAUTION:

Failure to follow the break-in procedure could result in reduced engine

life or even severe engine damage.

Procedure for 4-stroke models

Run the engine under load (in gear with a propeller installed) as follows.

1.For the first hour of operation:

Run the engine at 2000 r/min or at approximately half throttle.

2.For the second hour of operation:

Run the engine at 3000 r/min or at approximately three-quarter throttle.

3.For the next eight hours of operation:

Avoid continuous operation at full throttle for more than five minutes at a time.

4.After the first 10 hours:

Operate the engine normally.

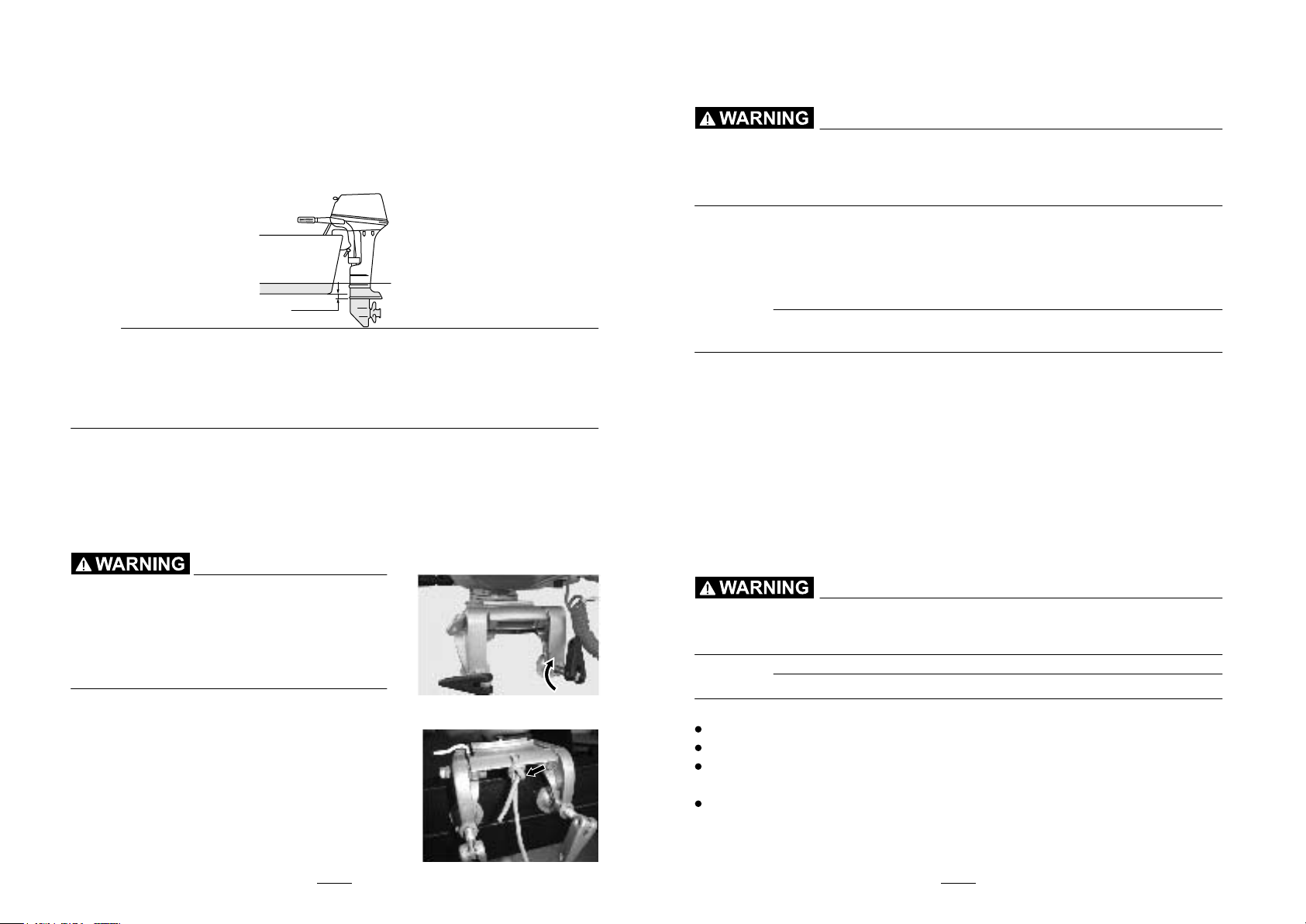

Preoperation checks

If any item in preoperation check is not working properly, have it inspected

and repaired before operationg the outboard motor. Otherwise an accident

could occur.

CAUTION:

Do not start the engine out of water. Overheating and serious engine damage can occur.

Fuel

Check to be sure you have plenty of fuel for your trip.

Make sure there are no fuel leaks or gasoline fumes.

Check fuel line connections to be sure they are tight (if equipped fuel tank

or boat tank).

Be sure the fuel tank is positioned on a secure, flat surface, and that the f-

uel lines is not twisted of flattened, or likely to contact sharp objects (if eq-

uipped fuel tank or boat tank).

0-25mm

(0-in.)