General information ...............................................

Identification numbers record .............................

........

Outboard motor serial number ............................

.......

Safety information .......................................

........

Important labels .................................................

Warning labels .................................................

Caution labels ............................................

.......

Fueling instructions .......................................

.......

Gasloine ..............................................

.........

Engine oil ..............................................

........

Porpeller selection ...........................................

....

Basic components .....................................

............

Main conponents ................................................

Fuel tank .............................................

.........

Fuel tank cap ............................................

......

Air vent screw ....................................

..............

Fuel cock .........................................

.............

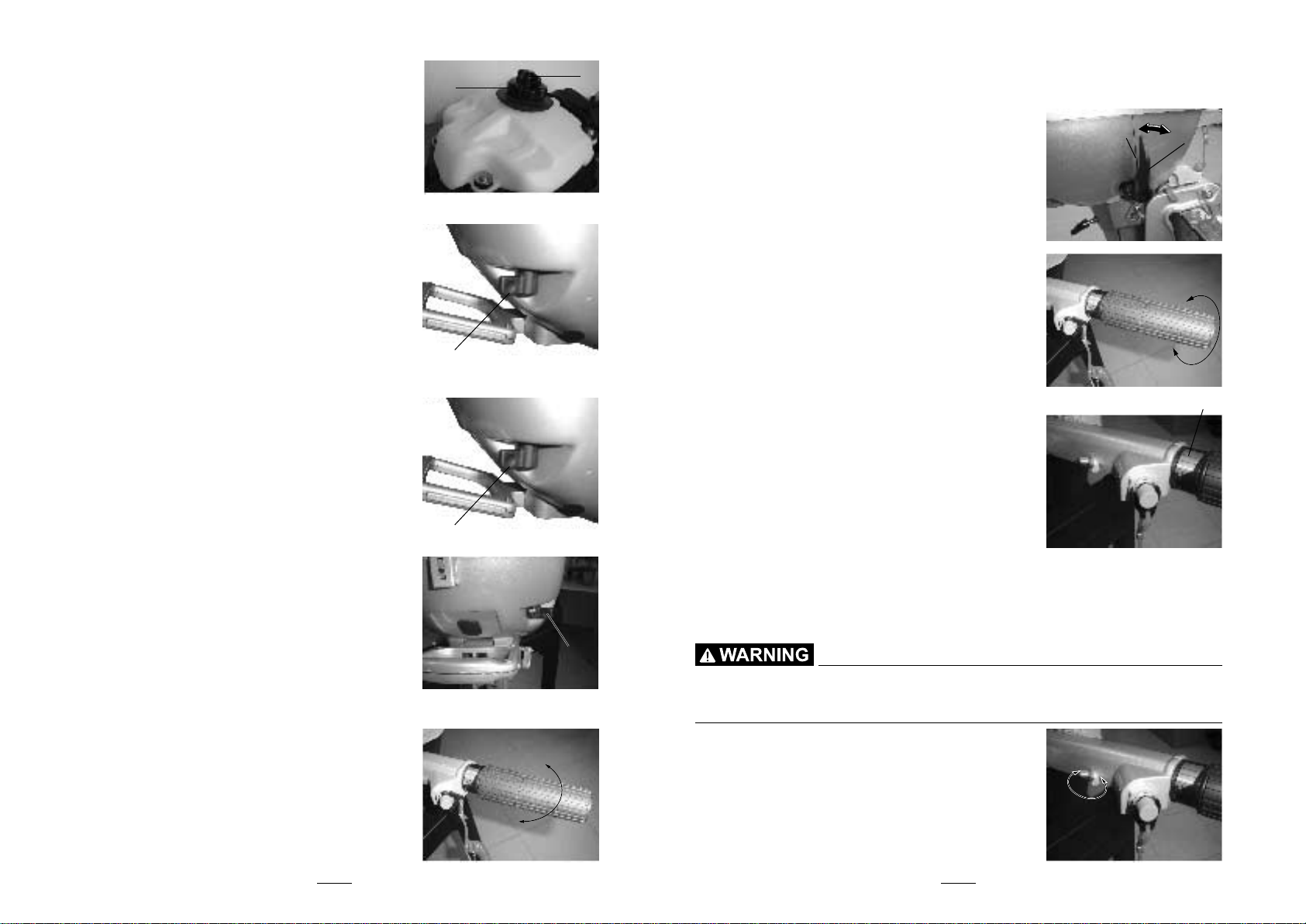

Tiller handle ...............................

.....................

Gear shift lever .................................

................

Throttle grip ....................................

................

Throttle indicator .............................

..................

Throttle friction adjuster .........................................

Engine stop lanyard switch ....................

..................

Engine stop button ...................................

..........

Choke knob for pull type ...............................

.........

Manual starter handle ..............................

.............

Steering friction adjuster ..........................

..............

Trim rod (tilt pin) ...............................

..................

Tilt support lever for manualtiolt model ..............

...............

Top cowling lock lever ............................

................

(pull up type) ................................

...................

Carrying handle ................................

.................

Breaking in engine ............................

...................

Procedure for 4-stroke models ..........

.........................

Preoperation checks ..............

...............................

Fuel ................................

...........................

Controls .......................................................

Engine ........................

................................

Checking the engine oil lever ....................................

Filling fuel .........................

.............................

Operating engine ................................................

Feeding fuel ........................................

...........

Starting engine ...............................

.................

Warming up engine ..............................................

Manual start models ............................................

Shifting .........................................................

Forward (tiller handle and remote control models) .................

Reverse .......................................................

Stopping engine ...............................

.................

.

Procedure .................................

..................

..

Trimming outboard motor ............................

.............

Adjusting trim angel for manual tilt models ........................

Adjusting boat trim ...........................

....

..............

Tilting up and down ....................

...........

..............

.

Procedure for tilting up (manual tilt models) .......

..............

..

Procedure for tilting down (manual tilt models) .........

..........

.

Specifications ......................................

..............

Periodic maintenance ..............................

..............

.

1

1

1

1

2

2

3

3

3

4

4

5

5

5

6

6

6

6

7

7

7

7

8

8

8

9

9

9

9

10

10

10

11

11

11

12

13

13

13

13

14

14

14

14

14

15

15

17

17

17

17

18

18

18

18

19

20

20

21

22

23

24

CONTENTS Operation .........................................................

Installation ........................................

..............

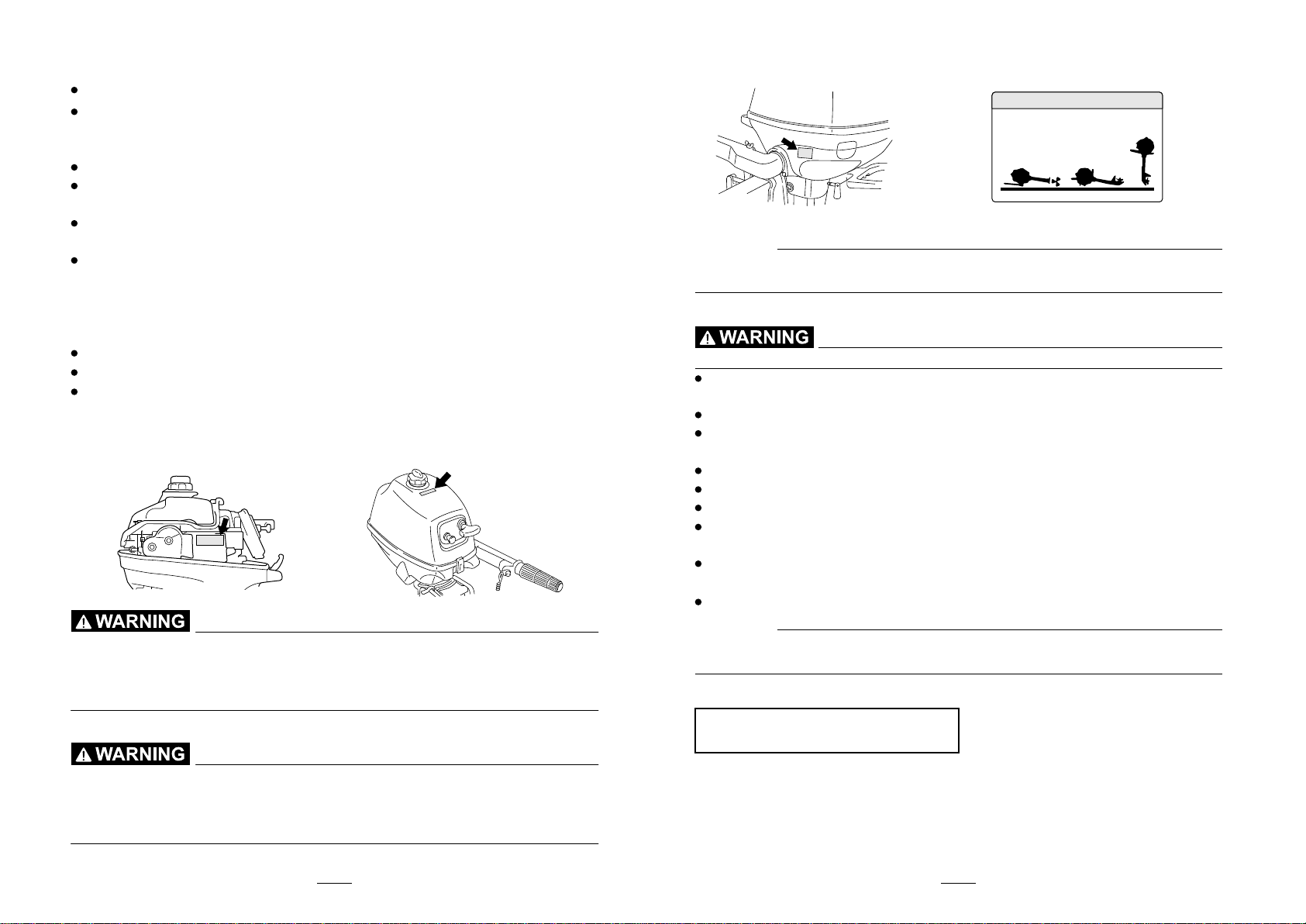

Mounting the outboard motor .................

...................

Clamping the outboard motor ...................

.................