3

SIG 6-17

www.salda.lt

• Setup, installation, con!guration, and initial start up of the heat pump system must be carried out by a quali!ed tech-

nician applying the relevant statutory rules, regulations, and guide- lines, as well as the operating instructions.

• The use of the heat pump must be reported to the local utility or electric company.

• Any work on the heat pump may only be performed by an authorized and quali!ed customer service.

• The heat pump must not be tilted more than max. 45° (in either direction).

• Avoid exposing the heat pump to any type of moisture or humidity.

• Protect the heat pump from damage and dirt during all construction phases

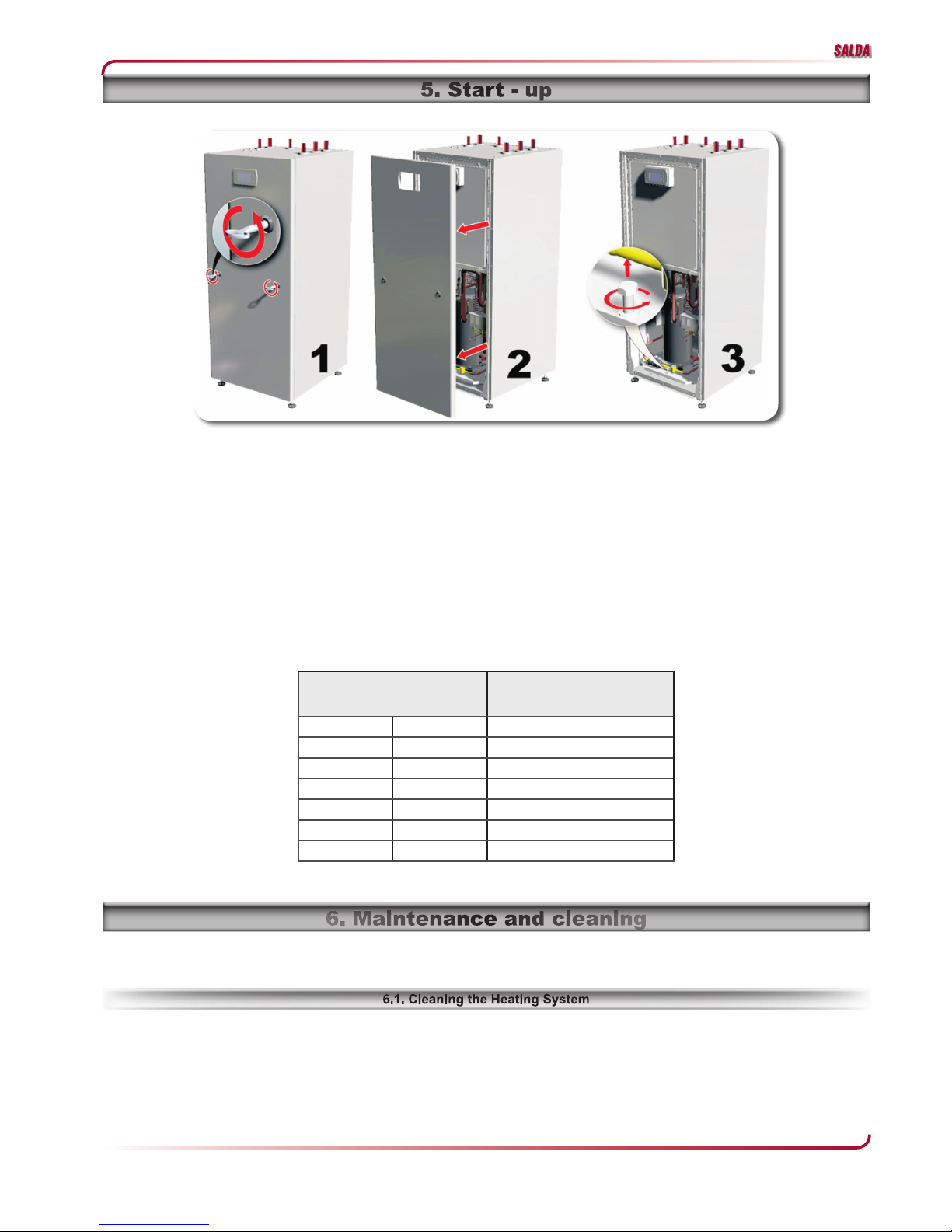

• The transport securing devices must be removed prior to commissioning.

• The heating system must be "ushed prior to connecting the heat pump.

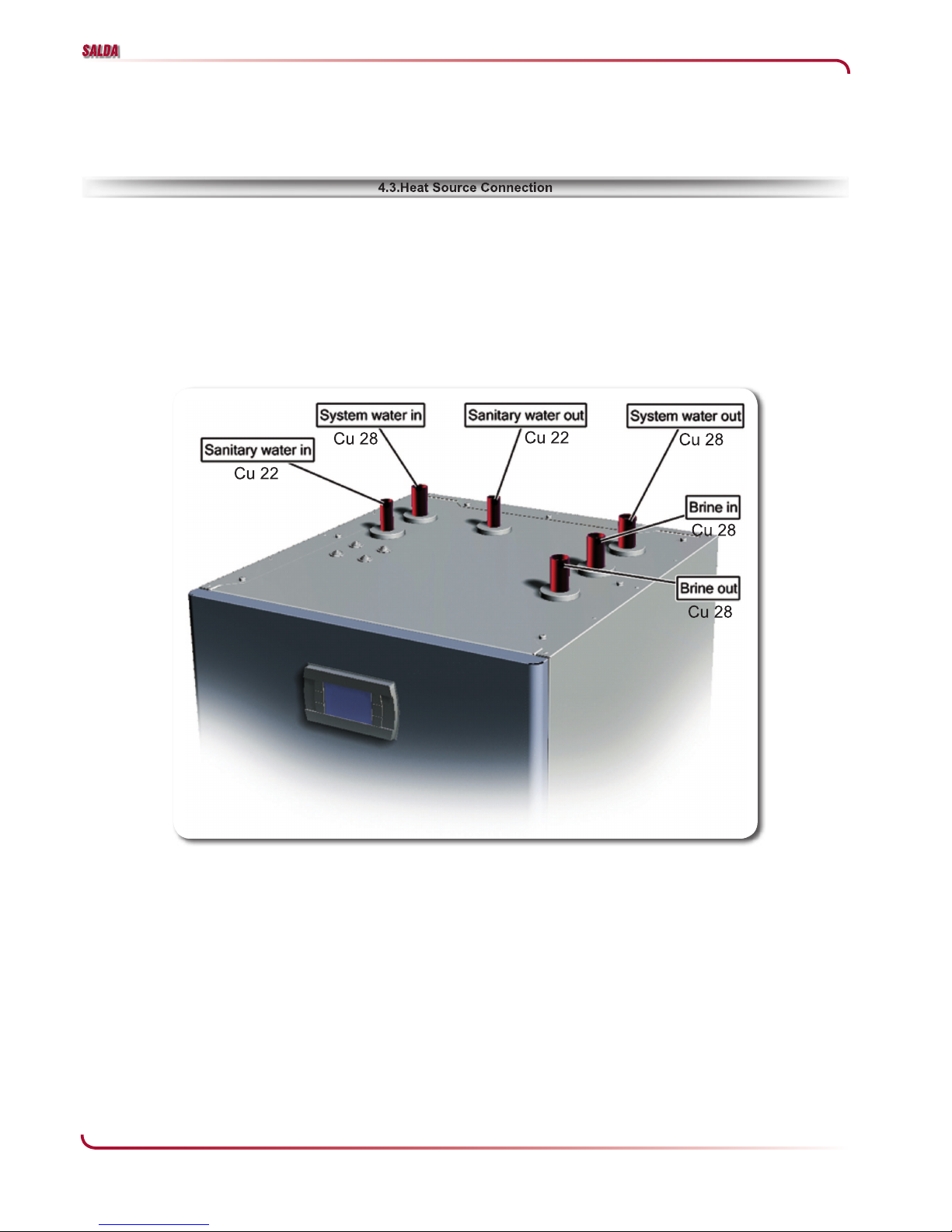

• The strainer must be !tted in the heat source inlet of the heat pump in order to protect the evaporator against the

ingress of impurities

• The brine solution must contain at least 25 % of an antifreeze agent on a mono-ethylene glycol or propylene glycol

basis and must be mixed prior to !lling.

• The clockwise phase sequence must be observed when connecting the load lines (the heat pump will deliver no out-

put and will be very noisy when the phase sequence is incorrect).

• To prevent the accumulation of deposits (e.g. rust) we recommend using a suitable corrosion protection system.

• Disconnect all electrical circuits from the power supply before opening the enclosure.

• Components and piping of the cooling circuit may never be used for transport.

• All work on the cooling circuit must be carried out by trained technicians who must be familiar with and trained in the

use and handling of the coolant.

• Never use harsh, abrasive, acidic or chlorine-containing cleansers on the surface of the equipment.

This device is only intended for use as speci!ed by the manufacturer. Any other use beyond that intended by the

manufacturer is prohibited. This requires the user to abide by the manufacturers product information. Please refrain

from tampering with or altering the device.

This heat pump is designed for use in a domestic environment according to Article 1, Paragraph 2 k) of EC direc-

tive 2006/42/EC (machinery directive) and is thus subject to the requirements of EC directive 2006/95/EC (low-voltage

directive). It is thus also intended for use by non-professionals for heating shops, of!ces and other similar working

environments, in agricultural establishments and in hotels, guest houses and similar / other residential buildings.

This heat pump conforms to all relevant DIN/VDE regulations and EU directives. For details refer to the EC Declara-

tion of Con formity in the appendix.

The electrical connection of the heat pump must be performed according to and conforming with all relevant VDE,

EN and IEC standards. Beyond that, the connection requirements of the local utility companies have to be observed.

The heat pump is to be connected to the heat source and heat distribution systems in accordance with all applicable

provisions.

Persons, especially children, who are not capable of operating the device safely due to their physical, sensory or

mental abilities or due to their inexperience or lack of knowledge, must not operate this device without supervision or

instruction by the person in charge.

Children must be supervised to ensure that they do not play with the device.

These operating instructions serve the correct installation, adjustment, and maintenance of the equipment.

The following information must therefore be read carefully and the heat pump must be installed, inspected, and

maintained by correspondingly trained technicians.

The manufacturer is not liable for mechanical, hydraulic, or electrical modi!cations after the warranty expires. The

warranty becomes null and void in case of not explicitly authorized actions carried out contrary to or in violation of

these operating instructions.

All applicable safety standards must be observed during installation. Check whether the properties of the power

supply system match those of the heat pump (type plate).

These operating instructions and the electrical scheme (diagram) of the heat pump must be stored carefully and

made available to the operating personnel if needed.

All guidelines based on CE standards were observed during design and manufacture of the heat pump. (See CE

Conformity Declaration (page 28)).

Compliance with the corresponding SEV, EN, and IEC standards is required for the electrical connection of the heat

pump. The connection speci!cations of the local utility or electric company must be complied with as well.