Salford Farm Machinery Ltd.

700 40' C-Shank Cultivator Assembly and Parts Manual 2011

09-2011

Table of Contents

General

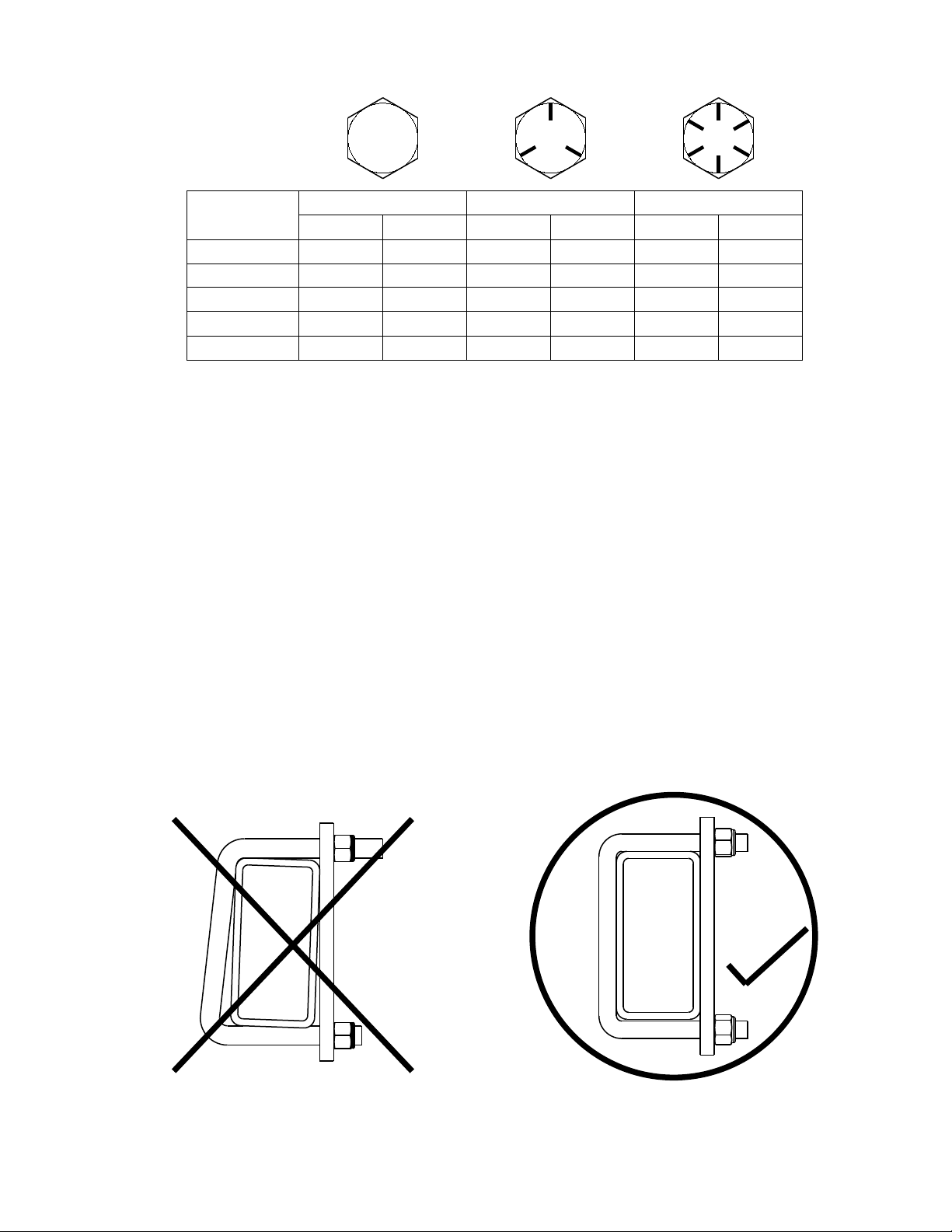

Salford Recommended Torque Values .........................................................................................................3

Torque Values for Tires ................................................................................................................................4

Pressure Values for Tires..............................................................................................................................5

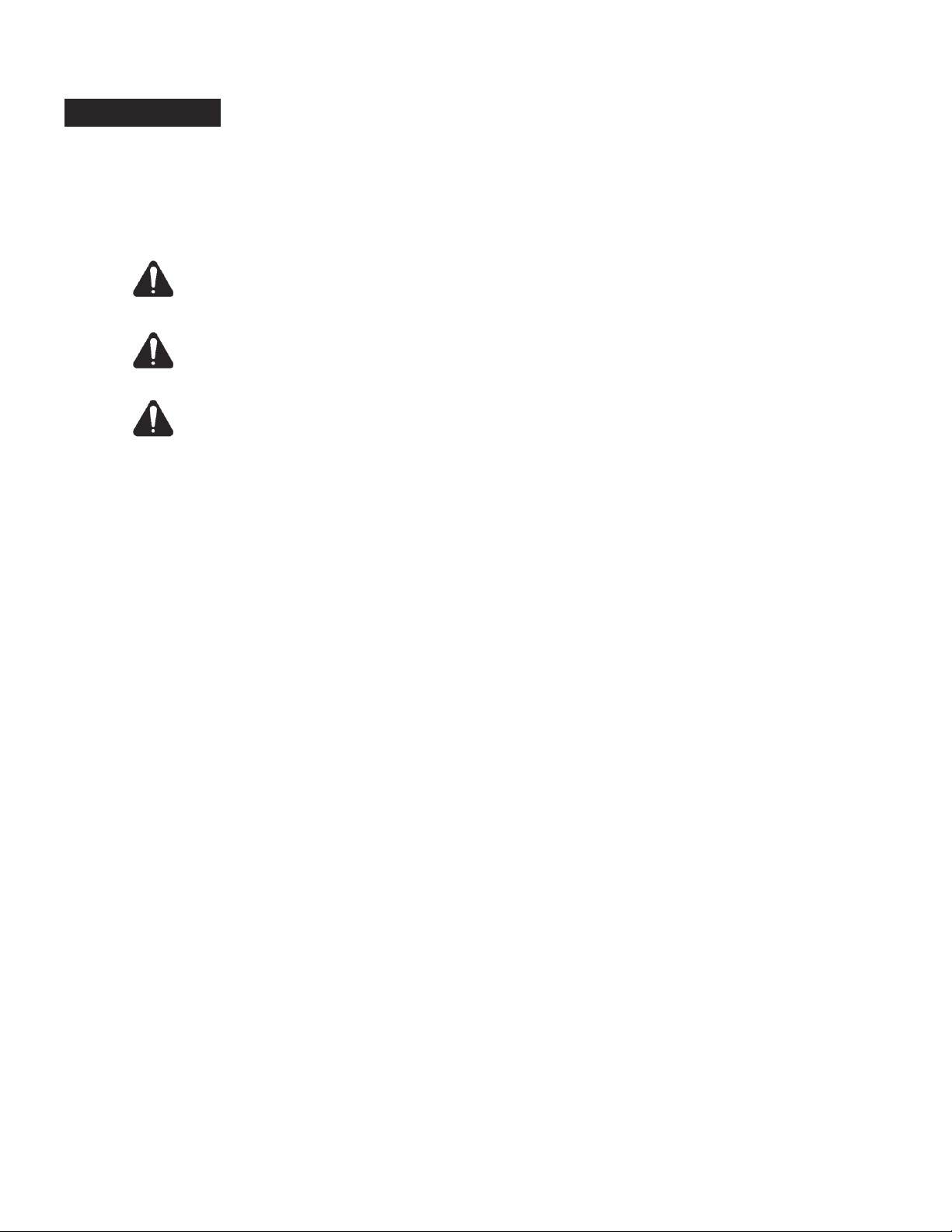

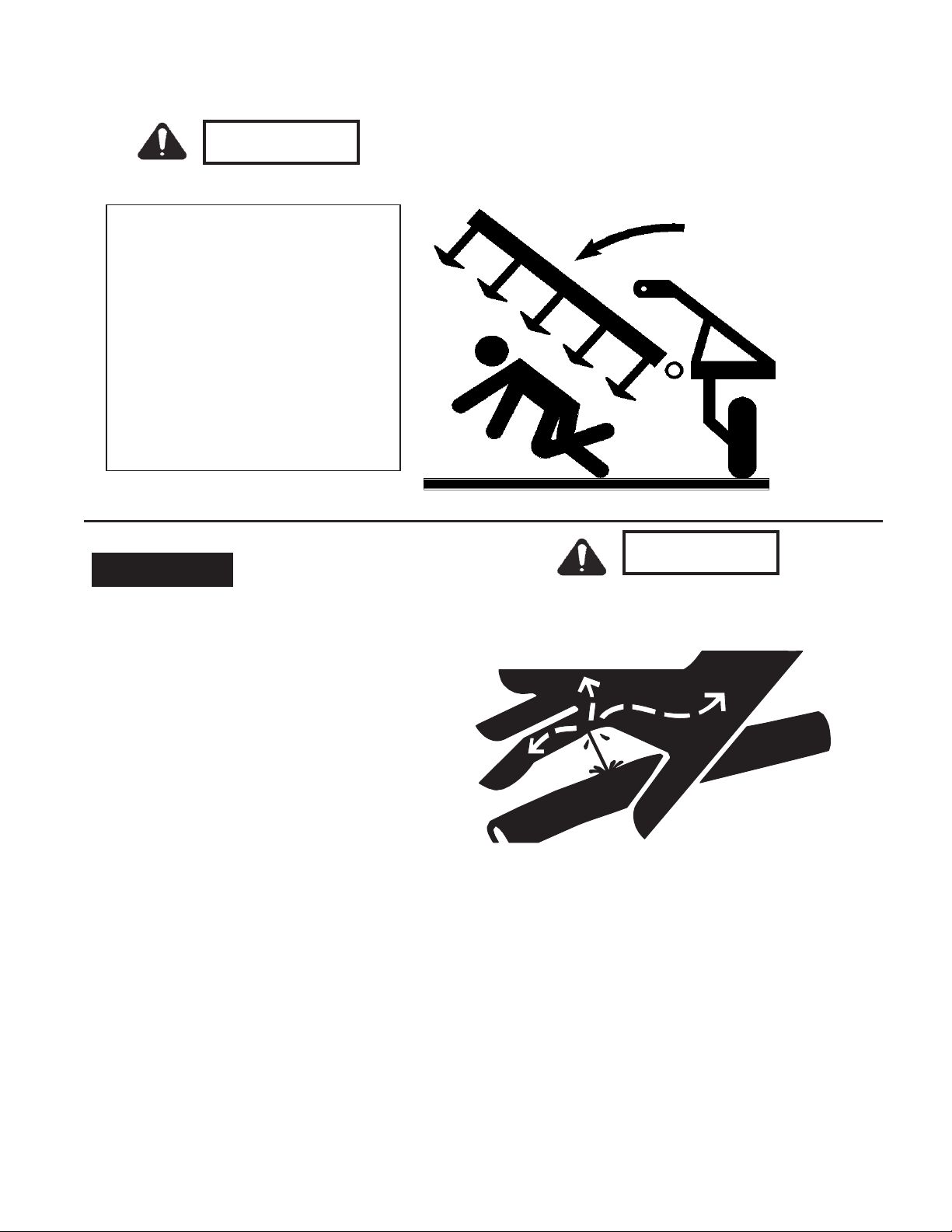

General Safety Precautions..........................................................................................................................6

Frame & Tongue

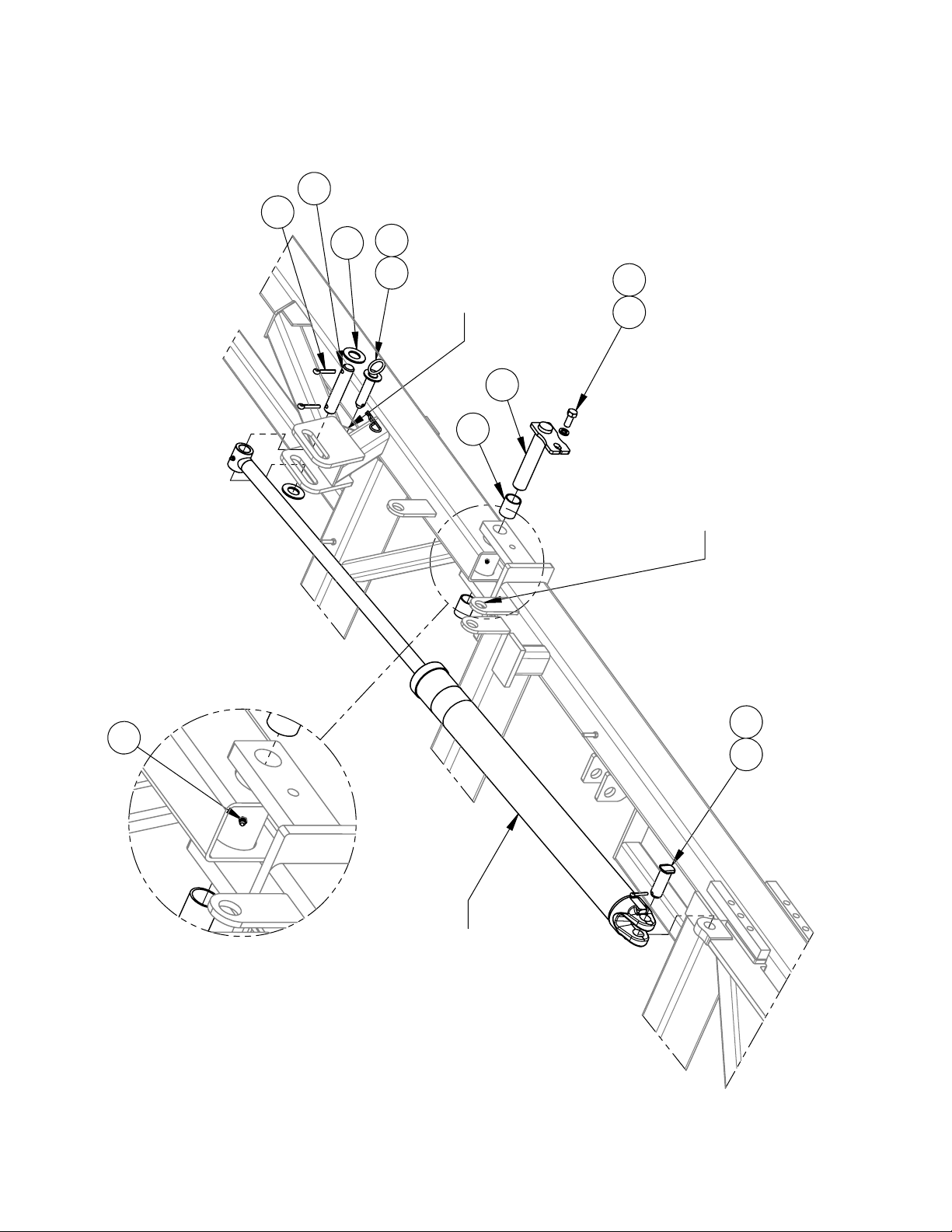

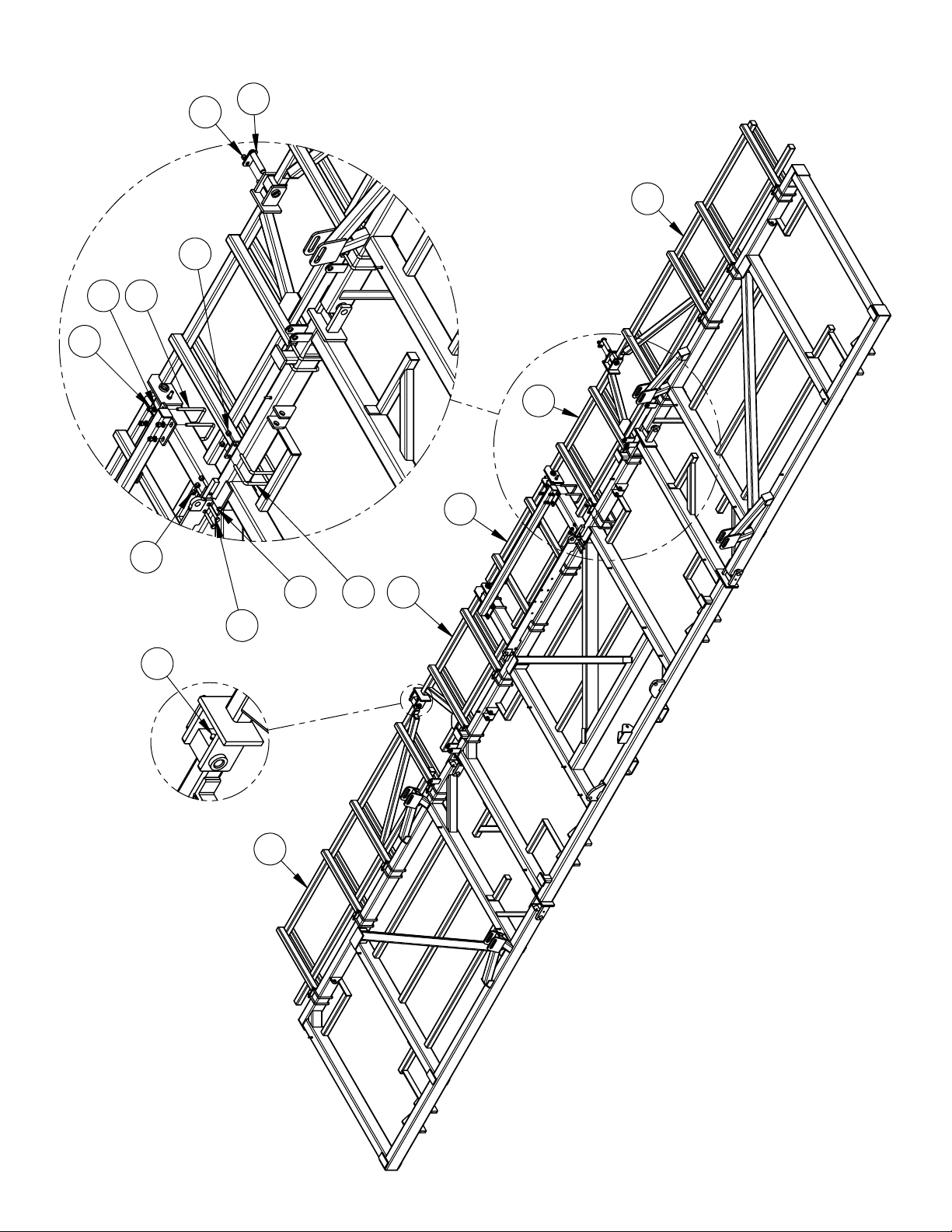

Primary Wing Installation ............................................................................................................................8

Front Bar Installation .................................................................................................................................10

Standard Tripod Installation.......................................................................................................................12

Land Hugger Tripod Installation................................................................................................................13

Standard Tripod & Depth Control Installation...........................................................................................14

Land Hugger Tripod & Depth Control Installation....................................................................................16

Tongue Installation.....................................................................................................................................18

Telescope Mount Hose Holder...................................................................................................................20

Axles

Wheel & Axle Layout ................................................................................................................................21

8000lb Axle Installation.............................................................................................................................22

8000lb Axle Assembly ...............................................................................................................................24

5000lb Axle Installation.............................................................................................................................26

5000lb Axle Assembly ...............................................................................................................................28

Standard Gauge Wheel Assembly & Parts.................................................................................................30

Land Hugger Gauge Wheel Assembly & Parts..........................................................................................32

4000lb & 5000lb Hub & Spindle Assembly ..............................................................................................34

Shank Parts

Shank Assembly & Parts............................................................................................................................36

Shank Head Assembly & Parts ..................................................................................................................38

40ft - 7in C-Shank Layout .........................................................................................................................40

Harrow Parts

40ft - 7in Harrow Layout ...........................................................................................................................41

Harrow Installation ....................................................................................................................................42

Harrow Arm Assembly ..............................................................................................................................44

Tine Harrow Assembly ..............................................................................................................................46

14” Roller Assembly ..................................................................................................................................48

Hydraulics & Lights

Axle Lift Hydraulics ..................................................................................................................................50

Wing Lift Hydraulics .................................................................................................................................52

Lights & SMV Installation.........................................................................................................................54

Decal Layout..............................................................................................................................................56

Decal Legend .............................................................................................................................................59

Optional Tow Hitch

Tow Hitch Installation................................................................................................................................60

Independent Tow Hitch Hydraulics ...........................................................................................................61

Shared Tow Hitch Hydraulics ....................................................................................................................62