-5-

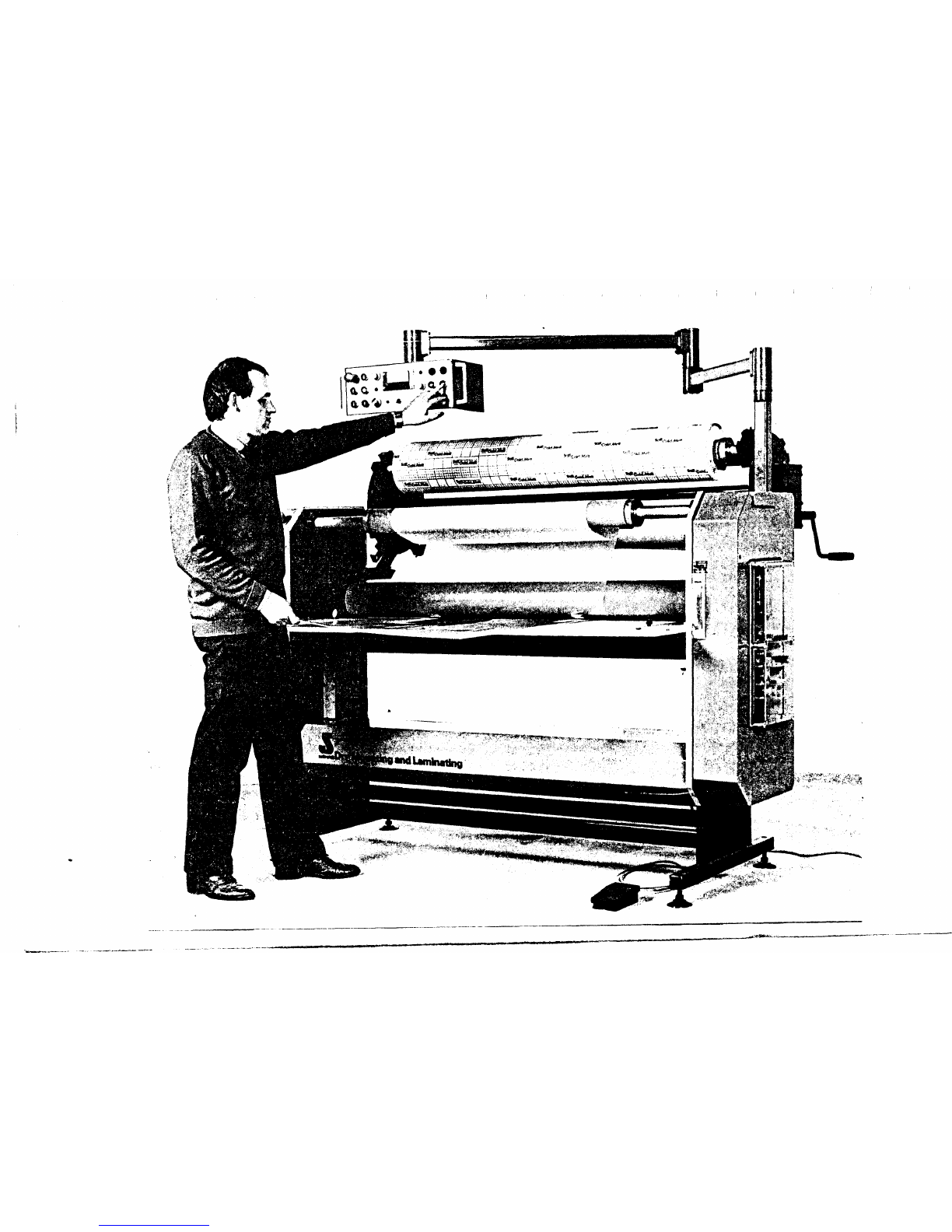

RUNNTNG PROCESS CONTROL LA]"IP

VÍhen foot pedal or forward run button is pushed the red control

Iamp will light up.

STOP SWITCH

FOR PRESSURE

ROLLERS

During a laminatj-on process in position automatic run, the process

can only be stopped by pushing the button stop.

After correction or inspection (of the picture, Iaminating process),

the process can be continued by pushing on button forward.

When holding the stop swj-tch you can control the wind-up motor

independent from main motor.

REVERSE

The reverse commandbutton only gives a reverse run when button

is pushed and speed.control has been turned up.

, SPEEDCONTROL

The pressure rollers can laminate with a variable speed from

0-8 mtr per minute (0-26 feet per minute).

Although the maximumspeed gives the user a quick resultr w€

suggest to run the machine with a lower speed, by way of

precaution.

This will give time to correct eventual problems, which might

show up (dust on the picture, creasing of a laminating film).

With the speed control you can start and stop the rollers and

wind-up motor (when itrs powered) after pushing the button

forward, the red control lamp should be in tight position.

I^IRfNKLE

CONTROL

By using the wrinkle control system, creasing of the mounting or

laminating film can be controlled.

Before starting a laminating process be sure the unwind shaft (FIG.6)

is in the middle position (the line on the shafts shoulC be in line

with the side of the beari.g).

This to be sure there is space to displace the unwind shaft.

When instructions are followed you will get a uniform, wrinkle and

bubble free bonding.

The right button moves the supply shaft to the right and the left

button moves the supply shaft to the left.