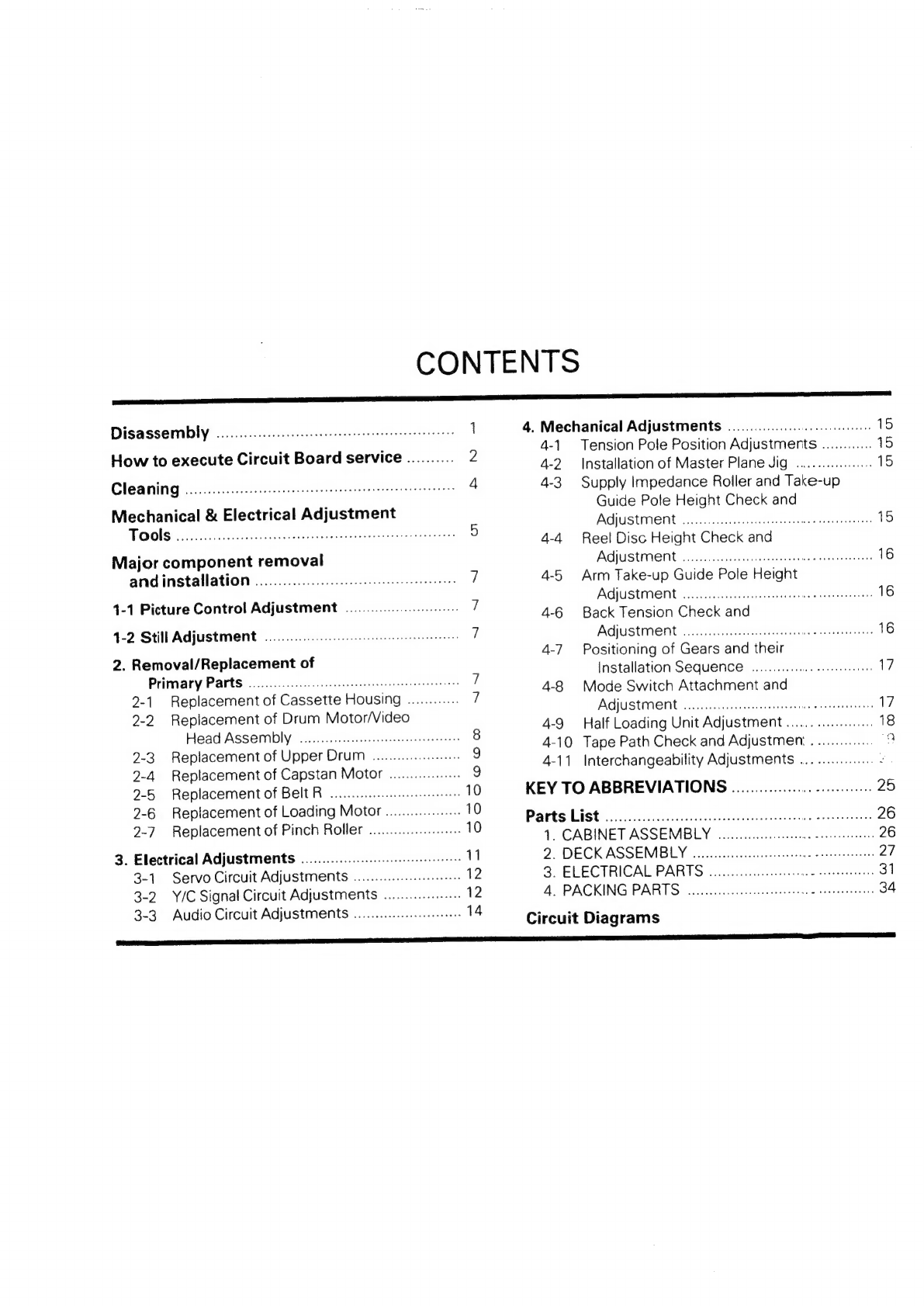

CONTENTS

Disassembly

...............0::::ccccecsceereettteetnneeees

1

How

to

execute

Circuit

Board

service

..........

2

Cleaning

oo...

ec

eecee

eter

ere

tee

eee

eteertettaes

4

Mechanical

&

Electrical

Adjustment

TOOISS

oo

efxkcehiie

ee

eee

5

Major

component

removal

and

installation

...................00-:c

eee

f)

4-1

Picture

Control

Adjustment

...................55

7

1-2

Still

Adjustment

20...

ee

7

2.

Removal/Replacement

of

Primary

Parts

..0.0...0..0000

cee

eee

7

2-1

Replacement

of

Cassette

Housing

............

7

2-2

Replacement

of

Drum

Motor/Video

Head

ASSEMDIY

........eccceceeeceeeteteteettees

8

2-3

Replacement

of

Upper

Drum

.............

Ss)

2-4

Replacement

of

Capstan

Motor

..............5

9

2-5

Replacement

of

Belt

Ro...

ee

10

2-6

Replacement

of

Loading

Motor

..............-5

10

2-7

Replacement

of

Pinch

Roller

..............

10

.

Electrical

Adjustments

.................

ee

11

3-1

Servo

Circuit

Adjustments

............

ee

12

3-2

Y/C

Signal

Circuit

Adjustments

..............-

12

3-3.

Audio

Circuit

Adjustments

...............

ee

14

ne

4.

Mechanical

Adjustments

................0.....:.:05

15

4-1

Tension

Pole

Position

Adjustments

............

15

4-2

Installation

of

Master

Plane

Jig

.............0.

15

4-3.

Supply

Impedance

Roller

and

Take-up

Guide

Pole

Height

Check

and

ACJUSTMENE

...c

sed

seetinnnea

taney

aes

15

4-4

Reel

Disc

Height

Check

and

AGJUStMONT

cas

cise

anaes

sas

16

4-5

Arm

Take-up

Guide

Pole

Height

AdjUStMENE

oo...

eee

ee

eee

rete

eres

16

4-6

Back

Tension

Check

and

ACjUStMENt

oo...

eee

cette

teeter

16

4-7

Positioning

of

Gears

and

their

Installation

SEQUENCE

.......

ee

cee

17

4-8

Mode

Switch

Attachment

and

AdjUStMENE

oo...

eee

cece

eect

eeteeteeneees

17

4-9

Half

Loading

Unit

Adjustment

..............05

18

4-10

Tape

Path

Check

and

Adjustmen:

.

............

me)

4-11

Interchangeability

Adjustments

...

0.0.0...

.,

KEY

TO

ABBREVIATIONS

.................

-.005

25

Parts:

List

.

3c

canes

seoniec

eels

26

1.

CABINET

ASSEMBLY

..........c

ce

crete

26

2.

DECK

ASSEMBLY

0.0...

cceeecceeee

eee

etteeenees

27

3.

ELECTRICAL

PARTS

.0.....

ccc

eccceccuce

ceteris

31

4.

PACKING

PARTS.

.......ccccccceeeeeeeeenee

tetreeetenes

34

Circuit

Diagrams

cee