sEcTtoN

3

ADJUSTMENTS

Nqtes UUhen Maklng Adjustments

l. Adjusunents should beperformed in the order listed-

2. Use the following testtapes:

TY-71

II (8-909-81

2-00).....................................

Lævel

TY

-7

252

(E-909-822-00)

... Tracking

TY-7551 (8-909-81400) .............Funcrions

TY-308 (E-892-35E-00)

......................................

Blank

Usethe following torque meten

TW-7131

(E-909-708-71) ............FwD

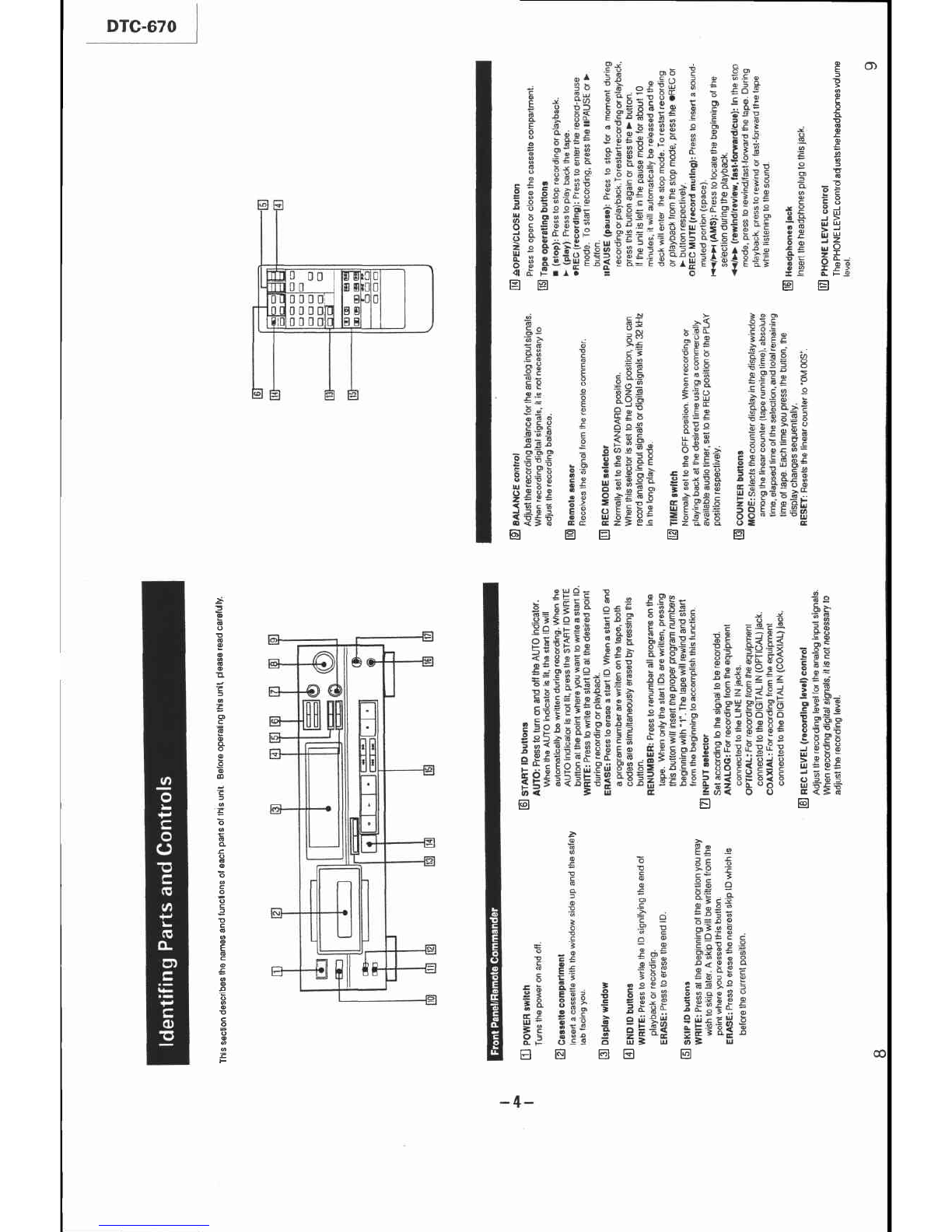

3. Swirches

andcontrolsshould

besetasfollows unlessotherwise

specified.

5. Cleaning

of theRevolving Drum

(1) Foldachamois

(2-034-697-00)

or aknir clothinto4 or more

files,

slightlyimpregnate

it wirhacleaning

liquid (9-919-573-

00),andsoftly touch thedrum with it andmanually roratethe

drum slowly counærclockwise by 2 to 3 turns for cleaning.

(2) At thatdme, becarefrrl not to movethechamoisvertically ro

the

headtip.

Otherwise,

theheadtipmayprobably

bedamaged.

6. Becarefulnot tomoveRV I andRV2 onrhe

RFAMP boardin the

mechanism

assembly.

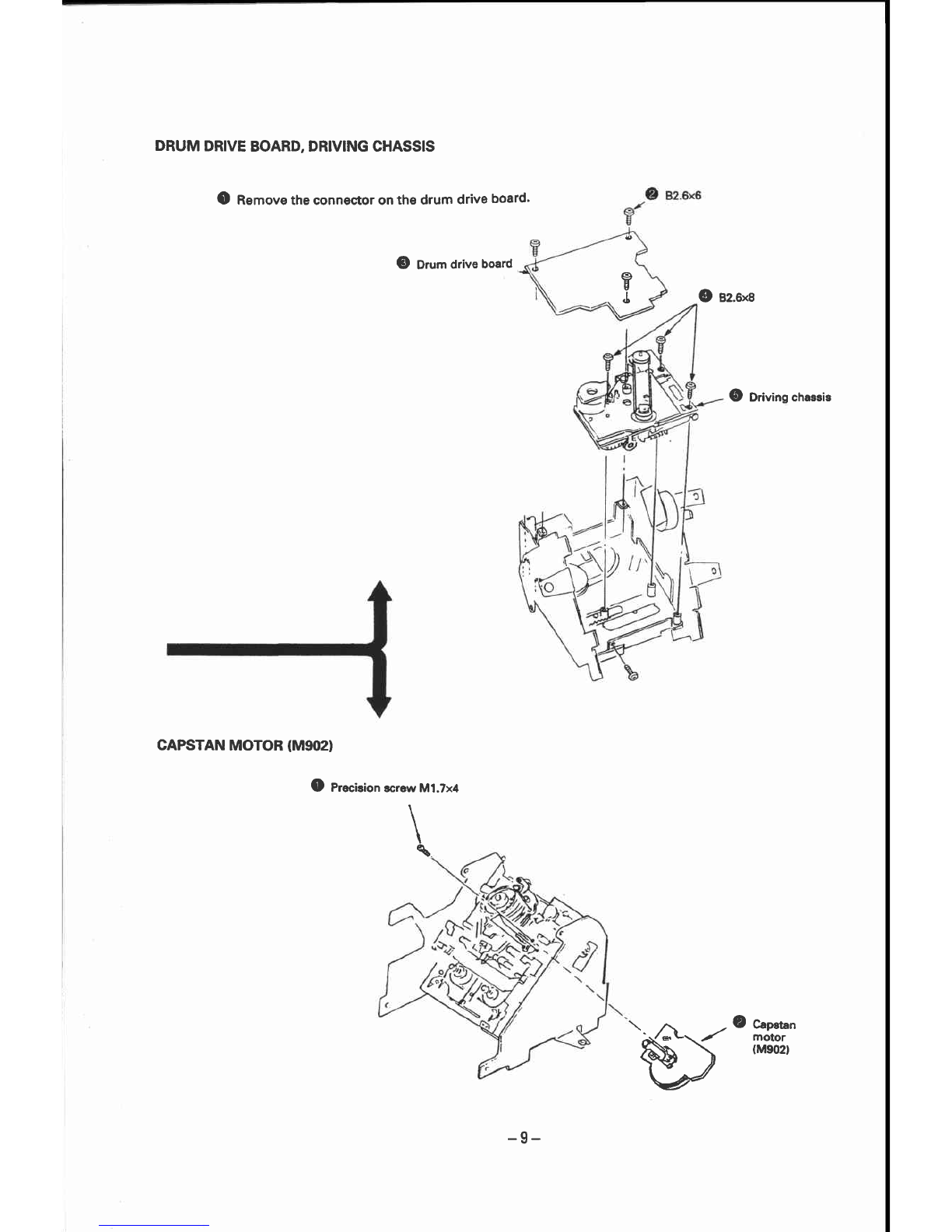

7. To adjustthe tapepath andguides,remove the holder

as

shown

inthediagram

andusetheDATholderjig

A). Thiswill makeit easier

to performadjusrments.

. Firstturning

the

pulley

counterclockwise

toput

itin

out stâtuswill. make removal and reattachment

of

holder

assemblyeasier.

. To performadjustmenE, turn the pulley clockwiseto put

in loading in status, load the cassette

tape and set the

switchto the ON position.

TIMERswitch

REC

MODEswitch

IMUT switch

REC

LEVELconnol

PHONES

LEVEL conrol

OFF

LONG

COAXIAL

Min.

Min.

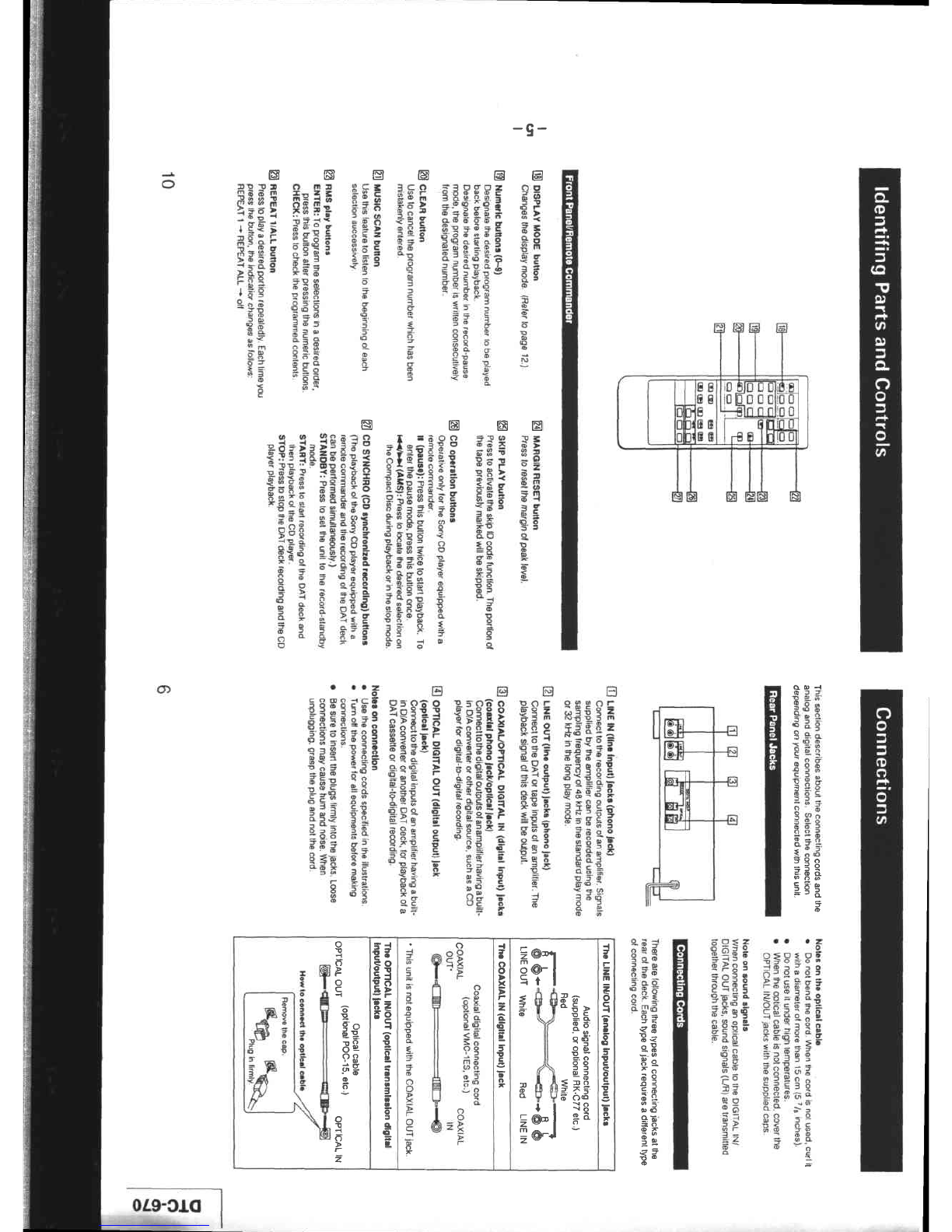

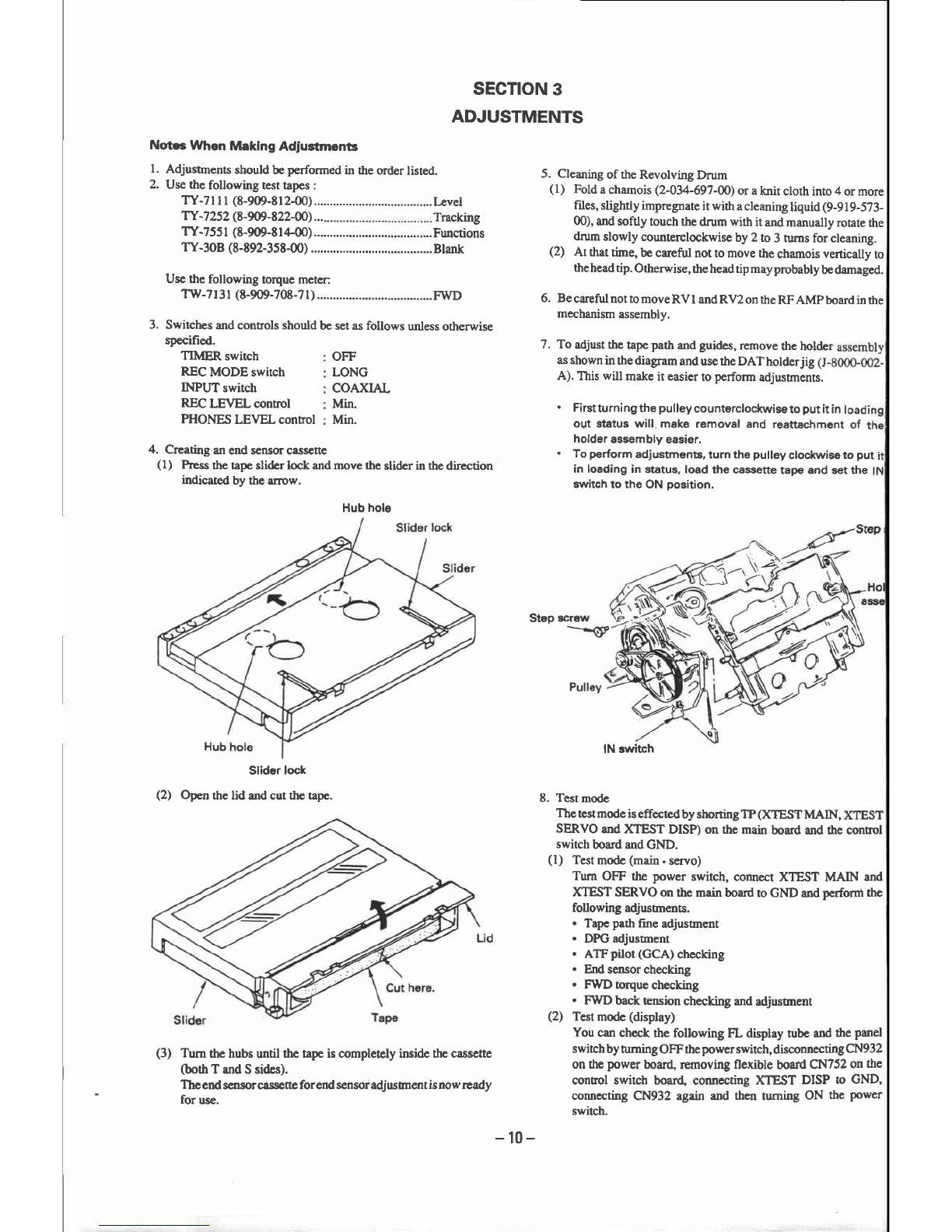

4. Creating anend sensorcassene

(l) Press

ûretapeslider lock andmove the slider in thedirection

indicated by the arrow.

Slider lock

(2) Opcn the lid andcut the tape.

Turnthe

hubs

untilthetapeiscompleælyinsidethecassette

(bothTandSsides).

The

ed sensorcassetteforend

sensoradjusrnentisnow

ready

for use.

IN3lrvitch

8. Testmode

Thetesmode iseffecædby shoningTP CXTESTMAIN,

SERVO

andXTESTDISP)onthemain

boardandthecontrot

switch

boardandGND.

(l) Testmode

(main.

sewo)

Tum OFF thepowerswitch,connecrXTEST MAIN and

XTEST

SERVOonthemainboard

toGNDand

perfonn

the

following

adjusunents.

. Tape

path

ftneadjustment

. DPGadjussnent

. ATFpilot(GCA)

checking

. Endsensorchecking

. F'WDrorquechecking

. FWD

backænsion

checking

andadjusrment

(2) Test

mode

(display)

Youcan

checkthefollowingFL displaytubeand

ttre

panel

switch

bytuming

OFFthe

power

switch,

disconnecting

CN932

onthe

power

board,removingfleûble board

CN752

onthe

controlswitch boand,

connecting

XTEST DISP to GND,

connccting

CN932againandthenturningON thepower

switch.

Step screw

---(P

Hubhole

(3)

-10-