4

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

1

2

3

4

5

6

7

3017793_E

Fig. 4

Fig. 5

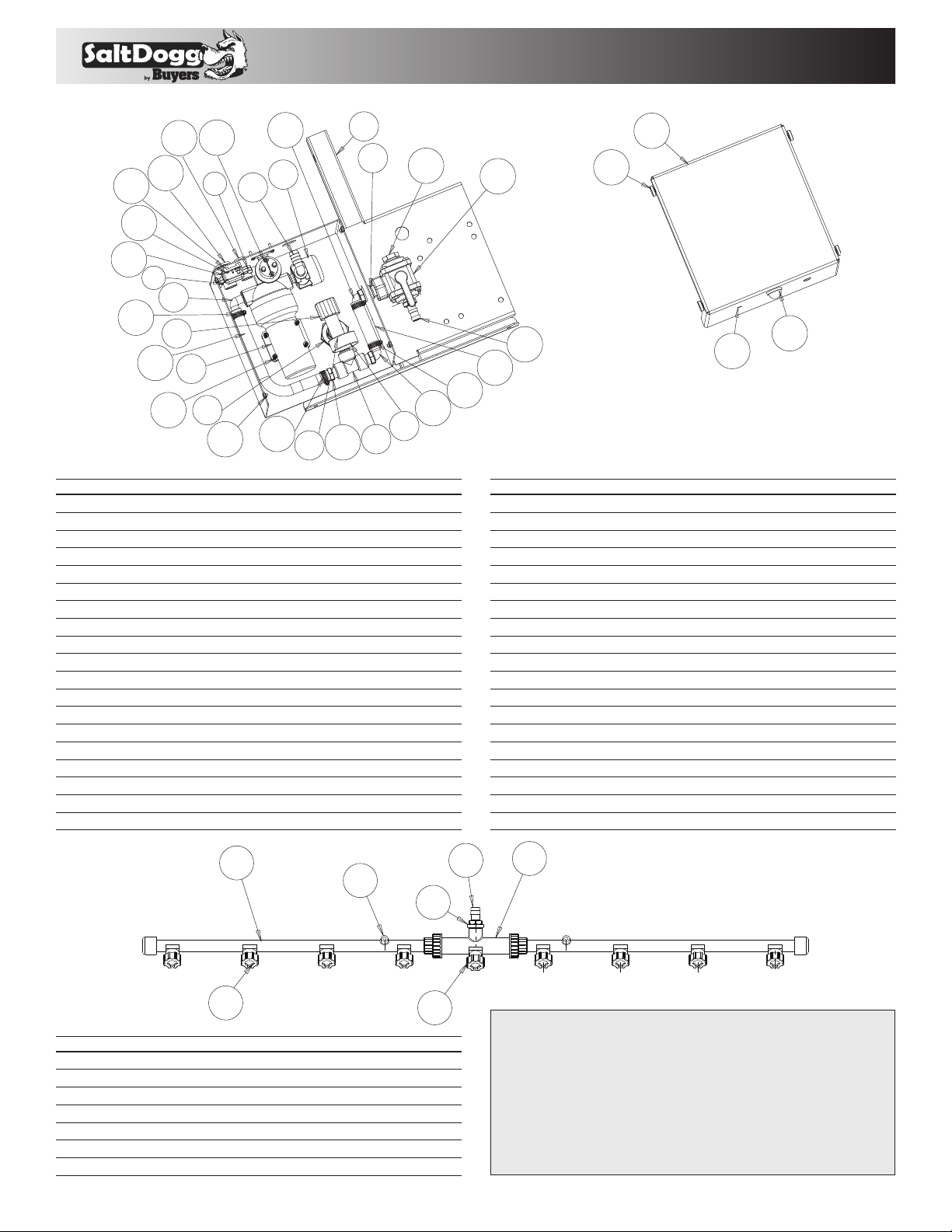

Bill of Materials

ITEM PART NO. QT Y. DESCRIPTION

13017780 1 Weldment, Base, Spray SYS

2 WSE90 A 1 Pump, 7 GPM, 80 PSI

3 WSE90 C 1 Strainer, Relief 1/2"

4 WSE90 D 2 Barb 90°, Quick Connect

5WSE92 1 Bulk Head Fitting 3/4"

6WSE102 2 Nipple, Hex, 3/4 x 3/4

7WSE93 1 Pressure Relief Valve, 3/4"

8HPGS100 1 Pressure Gauge 100 PSI

9WSE91 1 Tee Poly 3/4" x 3/4" x 3/4"

10 WSE99 2 Barb, Straight 3/4"

11 WSE112 1Barb, Hose, 90°

12 WSE116 1 3 Way Side Load Ball Valve

13 WSE126 1 Plug, 3/8 NPT, Poly

14 WSE128 5 in Hose 3/4" x 5"

15 3017789 1 Cover, Spray SYS, SS

16 5621534 1 Light, License Plate, LED

17 BBPF-3-8-3 2 Plug, Toolbox, Hanging Hole

18 WSE95 4 Clamp, Type F

19 3016933 4 Nut, Speed, U-Style, Extruded, 10-24

ITEM PART NO. QT Y. DESCRIPTION

20 3012194 4 Screw, Thumb Assembly, 10-24 x 3/4

21 WSE104 1 Strain Relief 1/2" NPT

22 WSE134 1 Strain Relief 3/4" NPT

23 WSE127 1 Hose 3/4" x 14"

24 WSE29 1 Nut, Plastic, 1/2" NPT

25 WSE105 1 Nut, Plastic, 3/4" NPT

26 WSE135 1Barb, Hose, 90°

27 WSE153 1 Harness, 10 GA. 12" Long

28 WSE141 1 Wire Harness, 14 GA. 36" Spray SYS

29 WSE156 1 Jumper, 10 GA. 12" Long

30 CB30PB 1 Breaker, 30 AMP

31 FBSH01002475SS 4 Screw #10-24 x .75

32 FNE010024024SS 8 Nut, Elastic Stop 10-24 SS

33 13047191 1Solenoid

34 3032351 4 #10-24 x 1-1/2" Machine Screw

WSE26 – 55 Gallon Poly Tank

3042685 – 210 Gallon Poly Tank

3045169 – 325 Gallon Poly Tank

3042687 – 550 Gallon Poly Tank

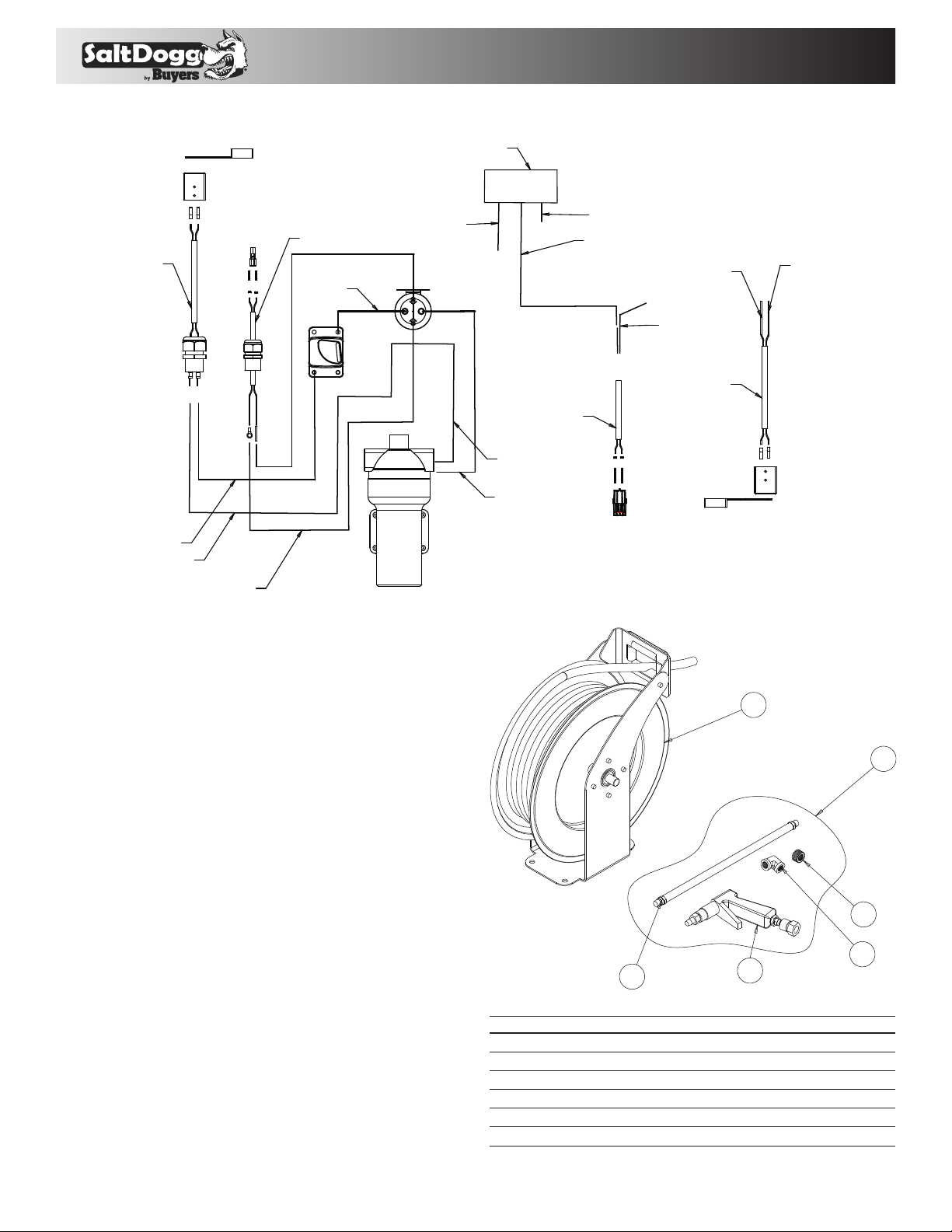

Bill of Materials

ITEM PART NO. QT Y. DESCRIPTION

1WSE160 1 Tee, Spray Bar

2WSE162 1 Barb Threaded, 3/4" Hose

3WSE157 2 Pipe, 1" PVC

4WSE159 8 Nozzle, Spray System, .5 GPM Each

5WSE163 2 Bracket, Support w/3/8" Bolt

6WSE133 1 Nozzle, Spray System

7WSE140 1 Barb Threaded, 3/4" Hose

WARRANTY

Buyers Products Co. warrants all truck/trailer hardware manufactured or distributed by it, to be

free from defects in material and workmanship for a period of one year from date of shipment.

Parts must be properly installed and used under normal conditions. Any product which has been

altered, including modification, misuse, accident or lack of maintenance will not be considered under

warranty. Normal wear is excluded. The sole responsibility of Buyers Products Co. under this war-

ranty is limited to repairing or replacing any part or parts which are returned, prepaid, and are found

to be defective by Buyers Products Co. Authorization from Buyers Products Co. must be obtained

before returning any part. No charges for transportation or labor performed on Buyers’ products will

be allowed under this warranty.

17

20

1

2

5

6

7

8

9

10

3

4 12

11

14

15

16

13

21

22

23

10

4

18

18

18

19

26

6

30

31

32

33

34

24

25