Content page

1. IDENTIFYING THE MACHINE .................................................................................................... 4

2. INTRODUCTION..................................................................................................................... 4

3. INTENDED USE AND DESIGN.................................................................................................... 5

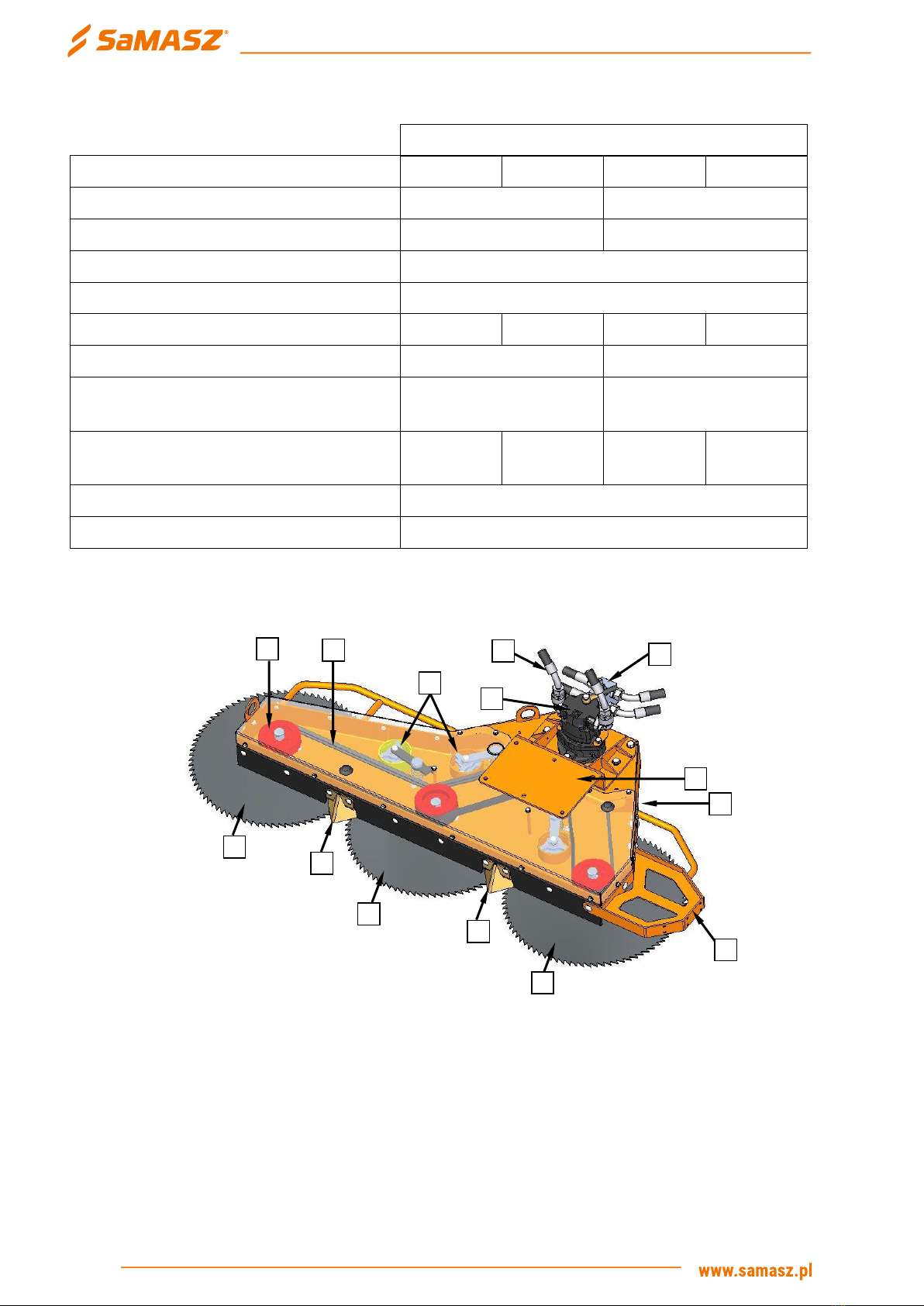

3.1. Technical data .............................................................................................................................. 6

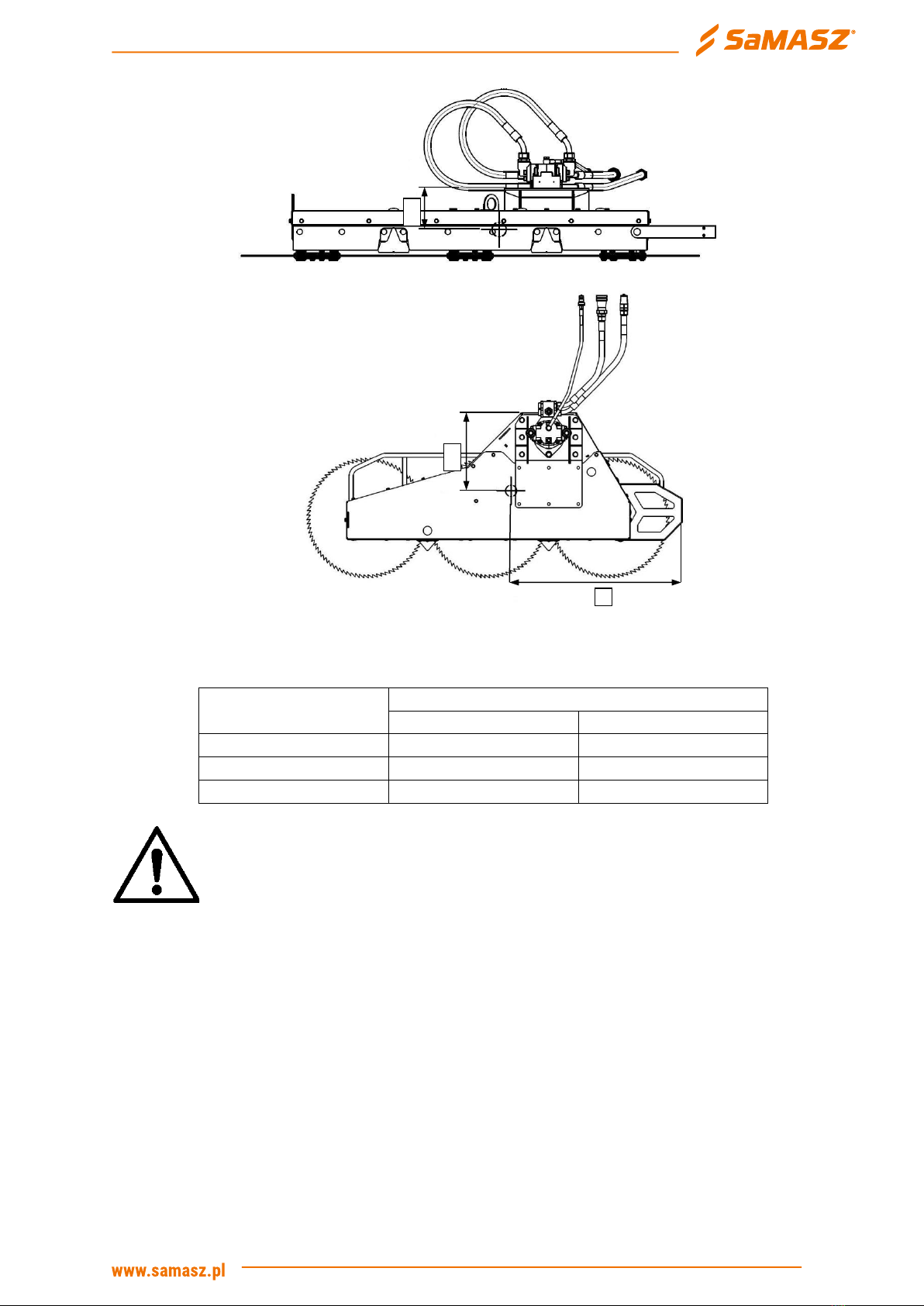

3.2. Design of circular saw ................................................................................................................... 6

3.3. Equipment and fittings:.................................................................................................................. 7

4. SAFETY PRECAUTIONS........................................................................................................... 7

4.1. General safety principles ............................................................................................................... 7

4.1.1. Connecting............................................................................................................................ 7

4.1.2. Transport .............................................................................................................................. 8

4.1.3. Transport and delivery ........................................................................................................... 8

4.1.4. Operating .............................................................................................................................. 9

4.1.5. Inspection and repair ........................................................................................................... 11

4.1.6. Replacement of damaged or worn parts................................................................................ 11

4.1.7. Storage ............................................................................................................................... 11

4.1.8. Qualifications of operator .................................................................................................... 11

4.1.9. Hydraulic assembly.............................................................................................................. 12

4.2. Residual risk ............................................................................................................................... 12

4.2.1. Danger of catching .............................................................................................................. 13

4.2.2. Danger of cutting limbs off................................................................................................... 13

4.2.3. Danger of injury and abrasion............................................................................................... 13

4.2.4. Danger of kick ..................................................................................................................... 13

4.2.5. Danger of damaging hearing ................................................................................................ 13

4.2.6. Danger of irritation to the respiratory tract............................................................................ 13

4.2.7. Danger of liquid ejection out of hydraulic system .................................................................. 13

4.3. Bans ........................................................................................................................................... 13

4.3.1. Residual risk evaluation ....................................................................................................... 14

4.4. Safety labels ............................................................................................................................... 14

5. USAGE................................................................................................................................16

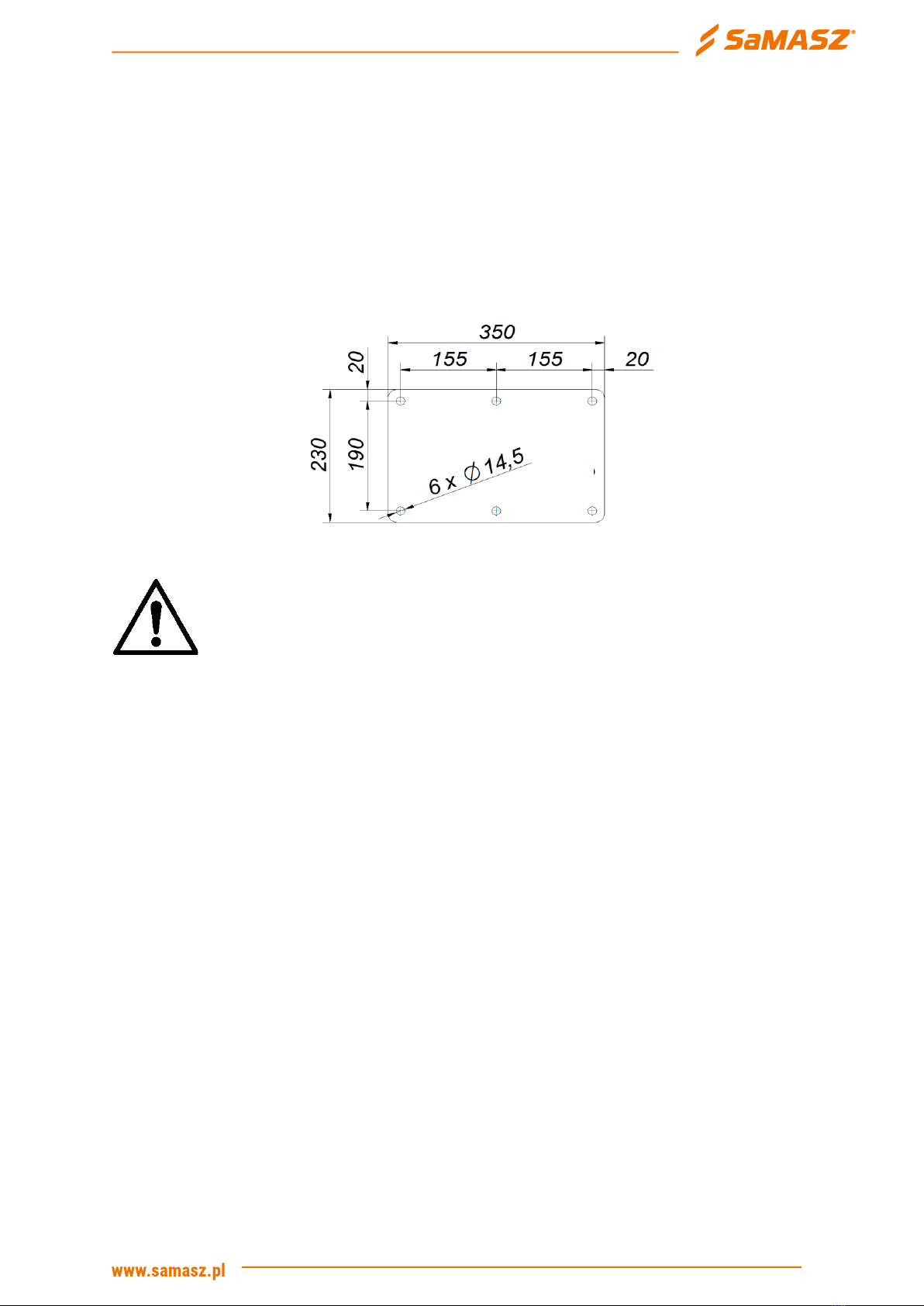

5.1. Coupling the circular saw and an extension arm ........................................................................... 16

5.2. Circular saw control..................................................................................................................... 16

5.3. Transport position and drive ........................................................................................................ 17

5.4. Preparing circular saw for operation............................................................................................. 17

5.5. Safe commissioning and shutting down ....................................................................................... 18

5.6. Operation.................................................................................................................................... 18

6. MOUNTING AND ADJUSTMENTS.............................................................................................19

6.1. Mounting and dismounting circular blades ................................................................................... 19

6.2. Checking belt tension .................................................................................................................. 19

6.3. Transmission v-belts ................................................................................................................... 20

7. DEFECTS AND THEIR REPAIR..................................................................................................21

8. MAINTENANCE AND STORING ................................................................................................21

9. DISMOUNTING AND WITHDRAWAL FROM USE...........................................................................22

9.1. Repair ......................................................................................................................................... 22

9.2. Disassembly and scrapping ......................................................................................................... 22

9.3. Environment................................................................................................................................ 22

10. WARRANTY CARD..............................................................................................................23

11. WARRANTY TERMS............................................................................................................23

11.1. Warranty claim procedure ........................................................................................................ 23

11.2. Warranty repairs record ........................................................................................................... 25