User's manual

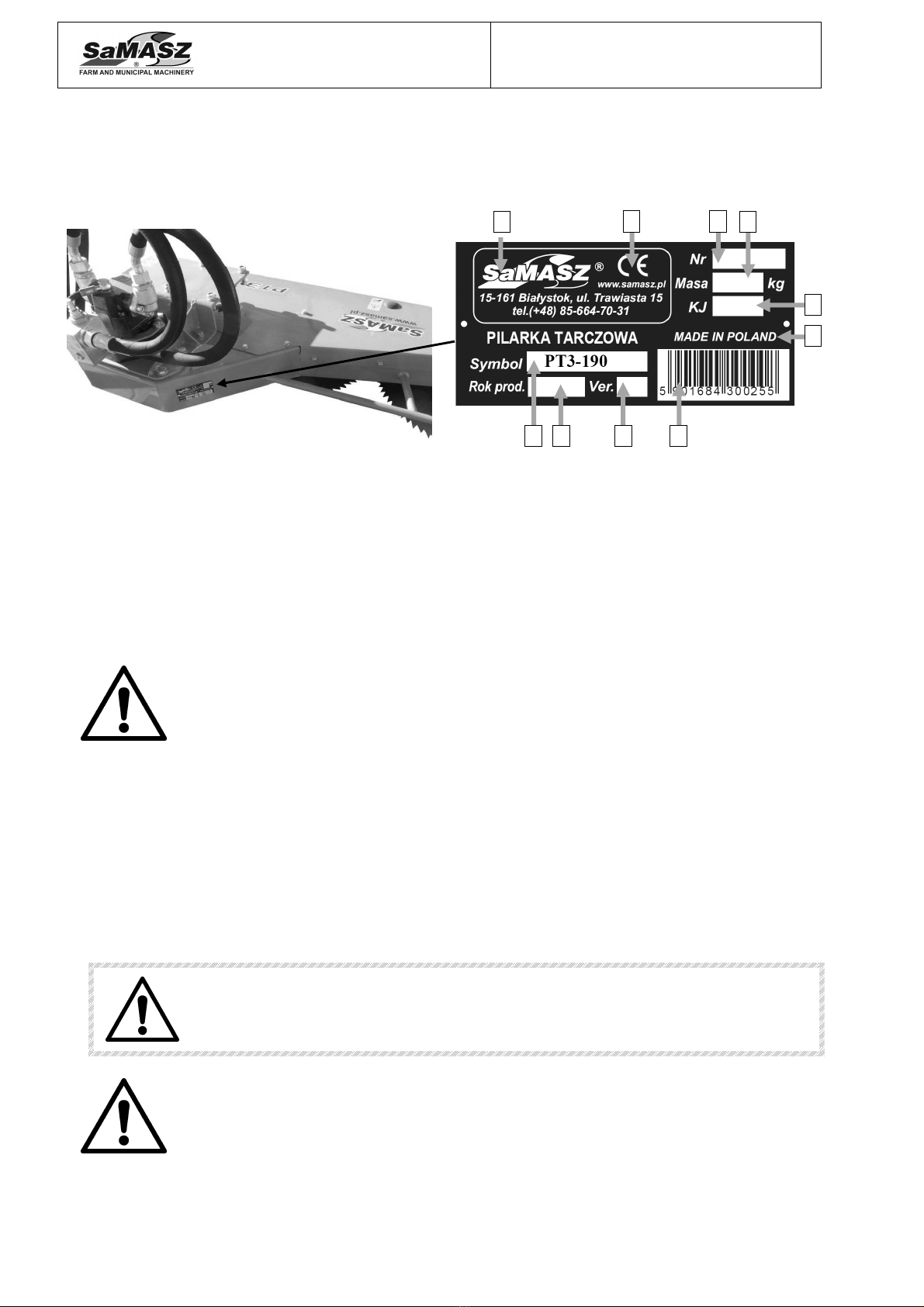

CIRCULAR SAW - PT

- 8 -

Transport

When driving on public roads always respect the local traffic regulations concerning warning

lights.

When approaching transportation of the aggregation of the arm and the circular saw, take off

or partially disconnect PTO shaft from the tractor’s side.

Prior to the transport protect circular blades with an additional protective guard.

When transported the arm-saw aggregate shall have mobile warning light device and warning

triangle mounted for a slow driving vehicle.

When transported the machine should always be set in transport position. See Fig. 6.

Any modifications in the circular saw's position are possible only if no vehicles or

unauthorized personnel are around (children in particular).

Driving speed should always be adjusted to current road conditions.

Do not exceed permissible speed of 25 km/h.

Operation

Unauthorized personnel and animals should be present in safe distance, which is at least 50 m

from the circular saw. Keep particular attention when operating near roads and lanes, where

presence of unauthorized personnel is likely.

When operating the arm-saw aggregation, the tractor should always be equipped with

operator's cabin.

Prior to operating, the machine should undergo a technical inspection paying particular

attention to condition of basic connections of machine’s assemblies as well as proper

mounting of the machine to a tractor.

Prior to commencing any works condition of circular blades must be examined, and if need

be, replaced with new ones.

Prior to starting tractor make sure that each drive is disconnected while control levers for

hydraulics are in neutral position.

Prior to moving make sure whether there are no unauthorized personnel directly nearby the

machine, give an acoustic signal.

The tractor’s engine must never be left running without supervision. Before leaving the

tractor, turn the engine off, set the aggregation of tractor and extension arm in standstill

position and take the ignition key out.

It is forbidden to drive the circular saw backwards when operating.

Cutting with the circular saw can only be started when PTO rpm rate reaches 540 or 1000 rpm

(depending on the extension arm used).

Perform any circular saw maneuvering only from the operator’s seat. DO NOT control from

outside the tractor’s cabin.

When cutting, the circular saw should be set so that the cutting plane is always parallel to the

tractor's driving direction and, if possible, perpendicular to the road surface.

Operating speeds of the tractor and the extension arm-circular saw combination should be

adjusted to operating conditions such as: size and volume of the branches being cut, degree of

the ground unevenness.

It is recommended to keep low operating speed – with low tractor gears engaged. Applying

higher speeds may lead to damaging the circular saw and also the extension arm.

Do not operate the circular saw after dusk.

DO NOT leave the aggregation on any slopes without any additional protection.

The operator is not allowed to leave the tractor while driving.

In the event of any break in the equipment operation, turn off the drive.

Bear in mind that when operating and transporting the machine in areas where high voltage

lines are present, special caution should be exercised due to possibility of contacting the

aggregate with the lines.