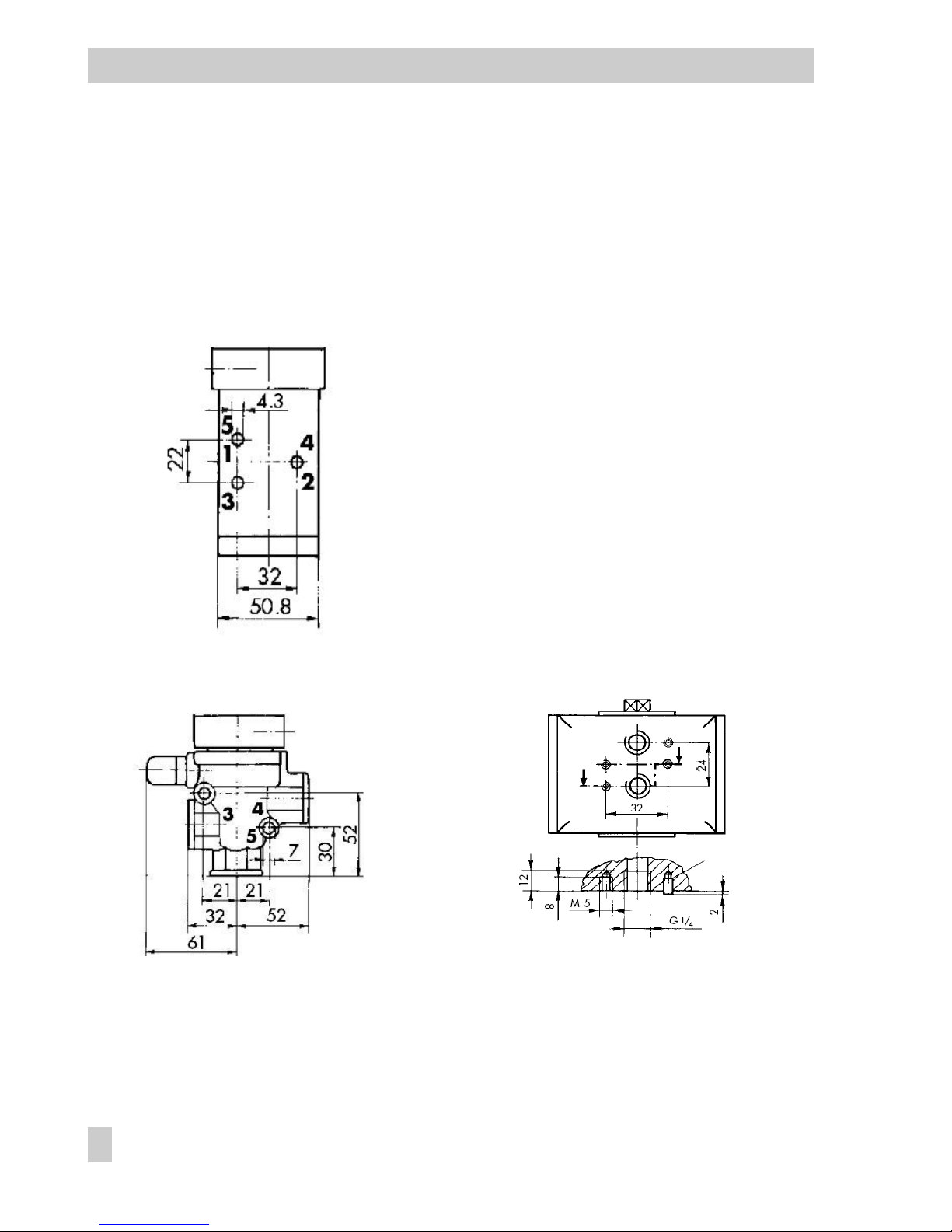

Pneumatic connections

2 Pneumatic connections

2.1 General

Make sure the connecting lines and screw

fittings are routed and installed properly.

Check them for leaks or damage at regular

intervals and replace or repair them, if ne-

cessary. Before starting any repair work, re-

lieve the pressure from the connecting lines

to be opened.

Depending on the solenoid valve version,

the pneumatic connections are established

using either G ¼/¼ NPT or G ½/½ NPT

threaded bores. Install filters or other suit-

able accessories to prevent water or dirt

from getting inside the housing through the

exhaust air connections.

Note! The KVS coefficient of an upstream

supply pressure regulator must be at least

1.6 times higher than the KVS coefficient of

the solenoid valve.

2.2 Connecting line

Refer to the following table for the minimum

required pipe sizes for the connecting lines:

Nominal size (connection length ≤2 m)

KVS 1.4 4.3 –

Connection

Pressure 1 and 3 4 9

≥1.4 bar ≥DN 8 ≥DN 10 ≥DN 4

≥2.5 bar ≥DN 6 ≥DN 8

≥6 bar ≥DN 4 ≥DN 6

Note! Use a larger nominal size for a con-

nection length of more than 2 m.

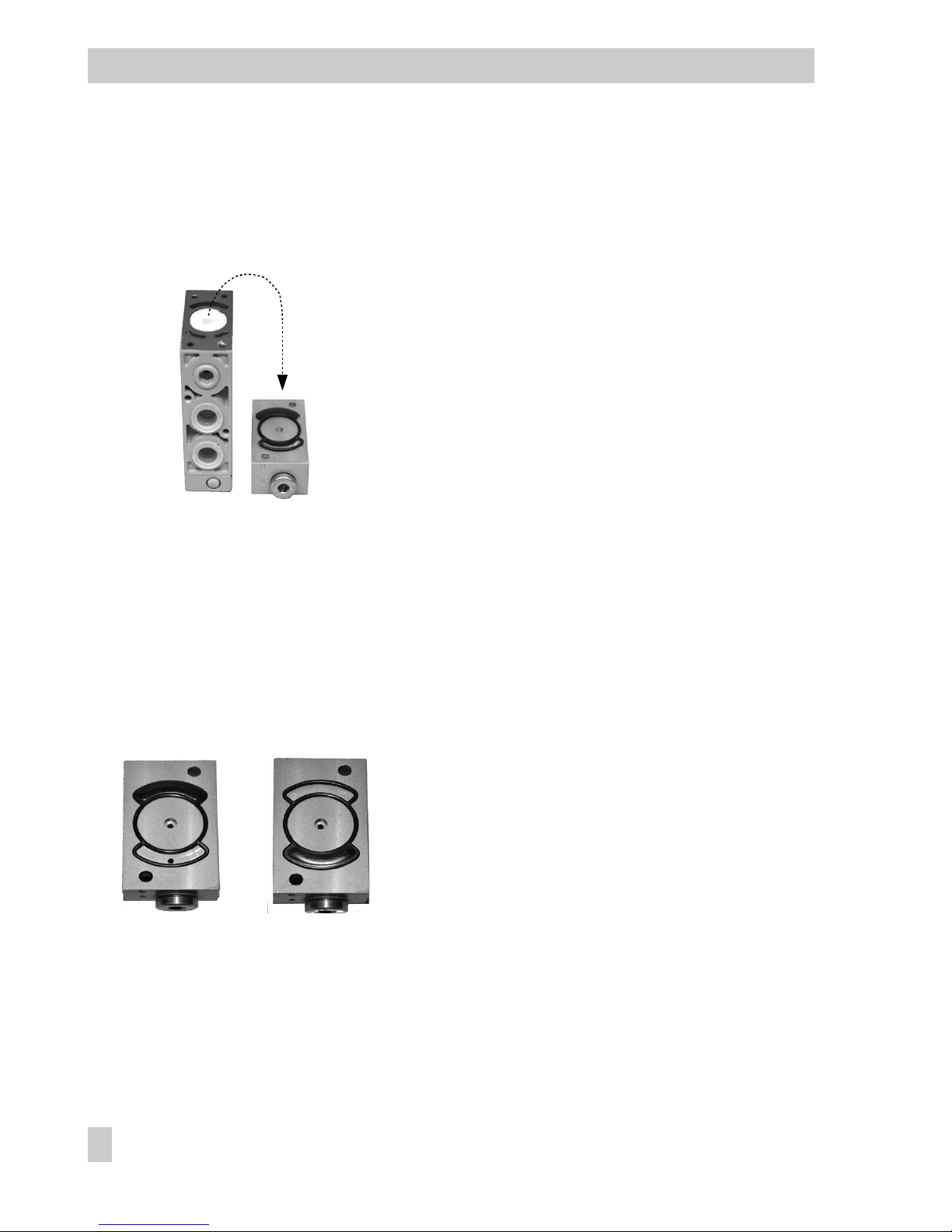

2.3 Operating medium for the

booster valve

With internal auxiliary air routing:

Instrument air free of corrosive contents or

nitrogen at 1.4 to 8 bar.

With external auxiliary air routing through

connection 9:

Instrument air free of corrosive contents, oil

or non-corrosive gases at 0 to 10 bar with

KVS coefficients between 1.4 and 4.3, supply

air fed through connection 4.

2.4 Auxiliary air for the pilot

valve

Instrument air free of corrosive contents at

1.4 to 8 bar.

Compressed air quality acc. to DIN ISO 8573-1

Particle size

and quantity

Pressure dew point Oil contents

Class 4 Class 3 Class 3

≤5 µm and

1000/m³ –20 °C or at least

10 K below the

lowest ambient

temperature to be

expected

≤1 mg/m³

Note on using nitrogen

If the solenoid valves are mounted in

closed, non-ventilated rooms, make

sure the pilot and booster valves' ex-

haust air is collected in a manifold

line and routed to the atmosphere.

6EB 3962-1 EN