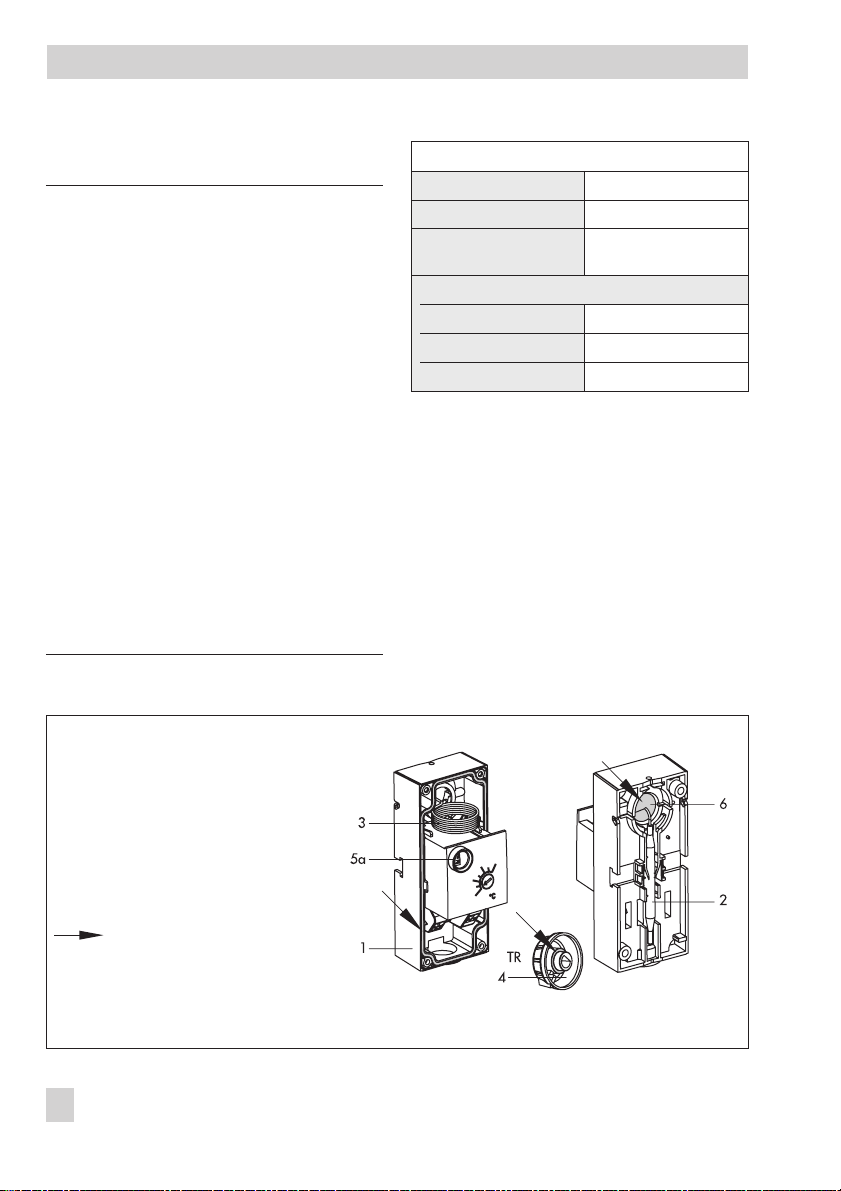

2 Design and principle of

operation

Safety temperature monitors (STM)

The snap-action switch is triggered if the

temperature at the bulb rises above the ad-

justed set point. When the temperature falls

below the set point by approximately 8 K,

the switch returns to its original position.

The electric circuit is opened when the tem-

perature at the bulb falls below –20 °C. The

circuit is automatically closed again when

the temperature at the bulb rises above

–20 °C.

The circuit remains permanently open if the

measuring system is broken.

Temperature regulators (TR)

The snap-action switch is triggered if the

temperature at the bulb rises above the ad-

justed set point. When the temperature falls

below the set point by approximately 4 K,

the switch returns to its original position.

Safety temperature limiters (STL)

The snap-action switch is triggered and

locked if the temperature at the bulb rises

above the adjusted set point. When the tem-

perature falls below the set point by approx-

imately 10 %, the snap-action switch can be

unlocked manually.

The electric circuit is opened when the tem-

perature at the bulb falls below –20 °C. The

circuit is automatically closed again when

the temperature at the bulb rises above

–20 °C.

The circuit remains permanently open if the

measuring system is broken. It is not possi-

ble to unlock the device.

2.1 Typetesting

The thermostats are typetested by the Ger-

man Technical Inspectorate (TÜV) according

to DIN EN 14597.

Type DIN register number

5343 STW120908

5344 TR120808

5345 STB120708

4EB 5206 EN

Design and principle of operation