Sensor Bar Touch TEST

How to Enter:

With the power on, pressing Wrinkle Prevent and Temp Keys for

3 seconds. This action will put the dryer into sensor bar touch

data mode. This mode is default mode of entering service mode

Cycle Count Test Mode How to Enter:

To enter cycle count mode press the Wrinkle Prevent in Service

Mode.

Software Version Test Mode

How to Enter:

To enter Special Test Mode press Temp Button until the control

beep. (same for all Frontier models.) ex) In case of “U105”, U0

means major version “v1“05 means minor version “05

Temperature Test Diagnostic Mode

How to Enter:

Press Adjust Time Up + Down Keys for 7 sec during

Power On State.

Press Adjust Time Up and it will display the temperature

in Celsius.

Compare vent temp to drum temp to see air flow.

This can be with just power on or dryer running.

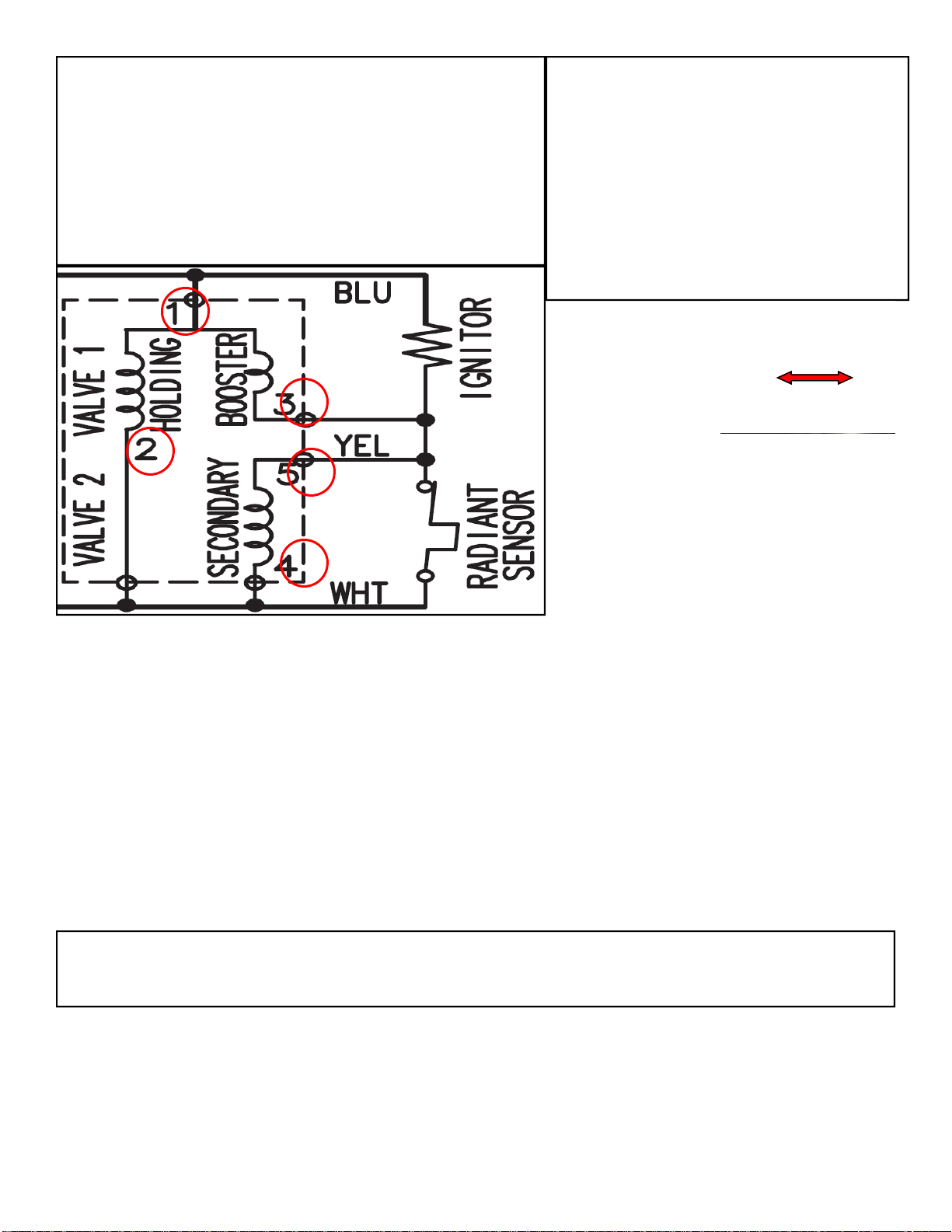

Gas Valve Testing

Unplug connectors and test valve terminals

(its numbering is from the front terminal.)

Check across terminals #1 and #3 (Booster Coil). 550 Ω

Check across terminals #1 and #2 (Holding Coil). 1350 Ω

Check across terminals #2 and #3 (Both coils in series). 1900 Ω

Check across terminals #4 and #5 (Secondary Coil). 1300 Ω

Dryer continues to run after cycle completed

Wrinkle Prevent option provides approximately 90 minutes (20 continuous and 70 intermittent) of tumbling in

unheated air at the end of the cycle to reduce wrinkling. Press the Wrinkle Prevent button to activate or deac-

tivate this feature. The indicator light above the pad will illuminate when Wrinkle Prevent is selected. Chasing

lights appear in the display when the Wrinkle Prevent option is selected. The load is dry, and can be removed

at any time during the Wrinkle Prevent cycle.

SUBJECT: Dryer belt slides off the pulley when

manually rotated counter-clockwise (ccw)

SYMPTOM: The dryer drum will not turn. On occa-

sions, the customer will rotate the drum counter

clockwise (CCW) to check for any remaining

clothes left in the dryer drum. By rotating the drum

CCW, the idler arm may shift causing the belt to

slide off the pulley.

SOLUTION: To prevent the dryer belt from sliding

off the pulley, the pulley has been redesigned.

The Outside Diameter has been changed from

22mm to 27mm.

New

DC81-00220A

Special Test Mode:

Press power button & Dry level buttons

simultaneously will put you in System Check Mode..

Display will show t2

Press Start/Pause to toggle through the following

operations

Motor (CW) relay on— Heater Relay on—- Heater

Relay Off—-Motor (CW) Relay Off

Do not use dryer to dry clothes which have traces of any flammable substance, such as vegetable oil, cooking

oil, machine oil, flammable chemicals, thinner, etc., or anything containing wax or chemicals, such as mops

and cleaning cloths. Flammable substances may cause fabric to catch fire by itself.

Make sure the idler pulley and the

motor pulley are straight in line

with each other, bend to correct

Service Mode:::

To enter Service Mode, press Wrinkle Prevent and Temp Keys for

3 seconds, until it sends out a beeping sound.