Operating Instructions and Installation

Samsung Electronics 1

Contents

11. Precautions

........................................................................................................................................

1-1

1-1 Installing the Ventilator

...................................................................................................................

1-1

1-2 Power supply and circuit breaker

.................................................................................................

1-2

1-3 During operation

..............................................................................................................................

1-2

1-4 Others

.................................................................................................................................................

1-3

12. Product Specifications

...............................................................................................................

2-1

2-1 The Feature of Product

....................................................................................................................

2-1

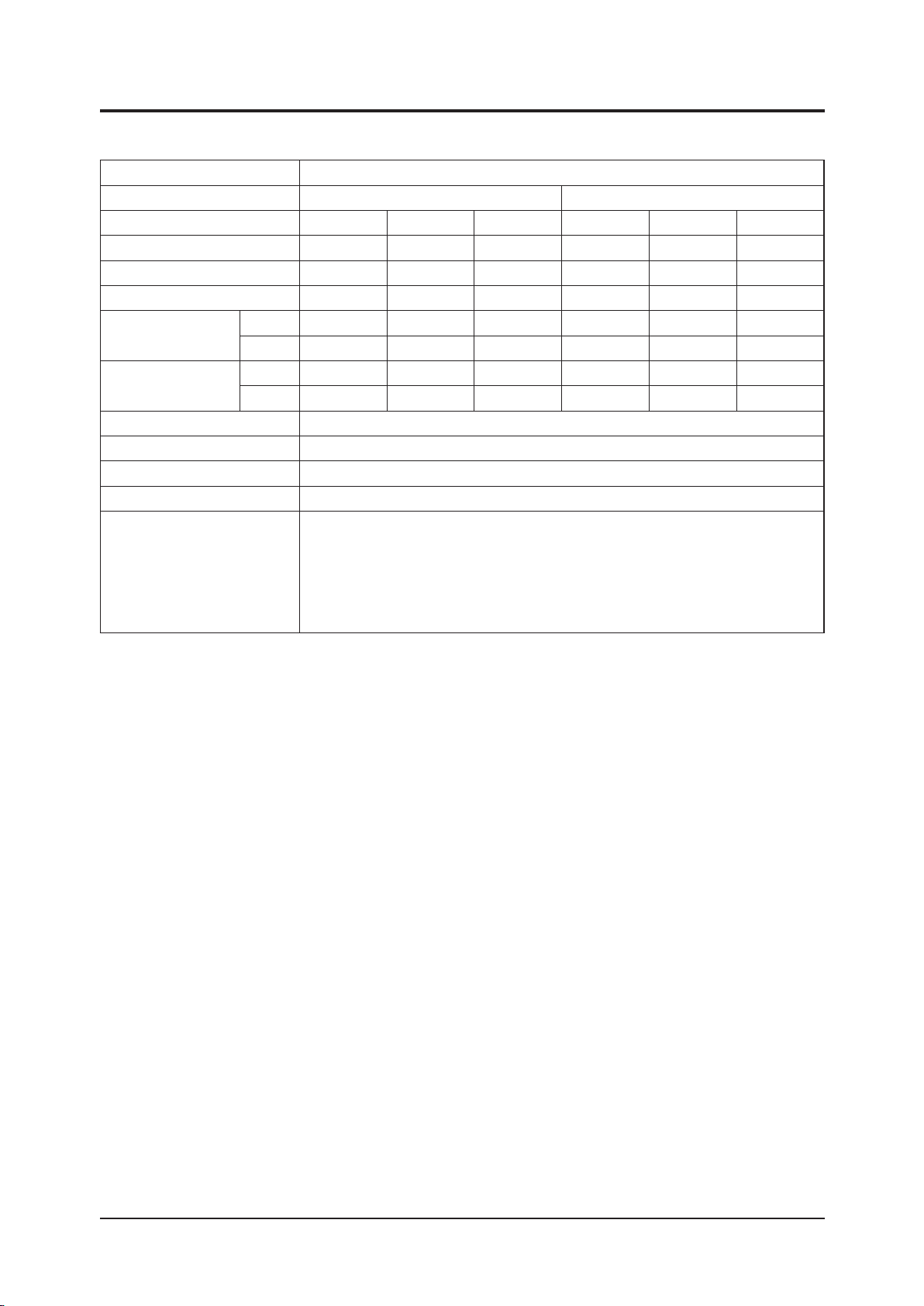

2-2 Product Specifications

.....................................................................................................................

2-2

2-3 The Comparative Specifications of Product

................................................................................

2-5

2-4 Option Specifications

......................................................................................................................

2-7

13. Alignment and Adjustments

.................................................................................................

3-1

3-1 Error Mode and Check Method

.....................................................................................................

3-1

3-2 Option Switch & Key Function Address

.......................................................................................

3-3

14. Disassembly and Reassembly

..............................................................................................

4-1

4-1 RHF025EE

...........................................................................................................................................

4-2

4-2 RHF035EE/RHF050EE/RHF080EE/RHF100EE

..............................................................................

4-16

15. Exploded Views and Parts List

.............................................................................................

5-1

5-1 RHF025EE

...........................................................................................................................................

5-1

5-2 RHF035EE/RHF050EE/RHF080EE/RHF100EE

...............................................................................

5-7

16. Electrical Parts List

.......................................................................................................................

6-1

6-1 MAIN PCB

...........................................................................................................................................

6-1

17. Wiring Diagram

..............................................................................................................................

7-1

18. Schematic Diagram

......................................................................................................................

8-1

19. Circuit Descriptions

......................................................................................................................

9-1

9-1 PCB Circuit Descriptions

..................................................................................................................

9-1

27723A(1)_RHF-025EB_1.indd 1 2007-05-09 ソタネト 4:22:56