SMH1713 2/17/2012 1

Fast Track Troubleshooting

Publication # rsSMH1713 Revision Date 1/20/2012

Model: SMH1713*/XAA

IMPORTANT SAFETY NOTICE –“For Technicians Only” This service data sheet is

intended for use by persons having electrical, electronic, and mechanical experience

and knowledge at a level generally considered acceptable in the appliance repair trade.

Any attempt to repair a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible, nor assume any liability for

injury or damage of any kind arising from the use of this data sheet.

SUPPORT INFORMATION

Training —Plus One http://my.plus1solutions.net/clientPortals/samsung/

Help —GSPN http://gspn3.samsungcsportal.com

Samsung Product Support TV http://support-us.samsung.com/spstv/howto.jsp

Customer information videos and chat programs. Programs for Fridges, Laundry, Ranges & D/W

Oven Thermal Cutout

The oven thermal cutout (Cavity TCO) is located on the top side of the oven cavity beside the exhaust duct with a tem-

perature rating of 248°F (120°C) and is NOT resettable.

Hood Thermal Cutout

This cutout will protect the touch control from excessive heat by turning the vent fan on at low speed. If the surface units

of the range are used for long periods of time heat will build up and could damage the microwave control. In order to pre-

vent this, a thermal cutout is installed on the duct behind the control. This cutout will close (158°F/70°C - vent fan ener-

gized) and open (104°F/40°C - vent fan de-energized) depending on temperature.

Magnetron Thermal Cutout

The magnetron thermal cutout is located above the leads to the magnetrons. It is designed to prevent damage to the

magnetron if an overheated condition develops in the tube due to cooling fan failure, obstructed air ducts, dirty or

blocked air intake. Under normal operation, the magnetron thermal cutout remains closed. However, when abnormally

high temperatures are reached within the magnetron, the magnetron thermal cutout will open at 302°F (150°C) causing

the oven to shut down. After the temperature drops to 140°F (60°C) it will reset and cooking will be able to resume.

Bottom Thermal Cutout

During a fire on the stove the heat could be intense enough to close the Hood Thermal Cutout and force the fan to run.

While at moderate high temperature we do want it to run, however during a fire it is advantageous to NOT have the vent

fan running. So if a fire were to start on the stove top the Bottom Thermal Cutout would open at 248°F (120°C) and re-

move all power to the microwave oven. This cutout is NOT resettable.

Error Code Cause and countermeasure

-SE- Key short error (10 sec.). Replace assy. control

panel or smart board.

E-11 Sensor open error. Check unplugged sensor, wiring

or smart board. If necessary, replace sensor. If

error code appears when starting sensor function,

replace smart board.

E-12 Sensor short error. Check shorted sensor or smart

board. If necessary, replace sensor. If error code

appears when starting sensor function, replace

smart board.

E-13 Sensor T1 max time error. Check sensor. If neces-

sary, replace sensor. If error code appears when

starting sensor function, replace smart board.

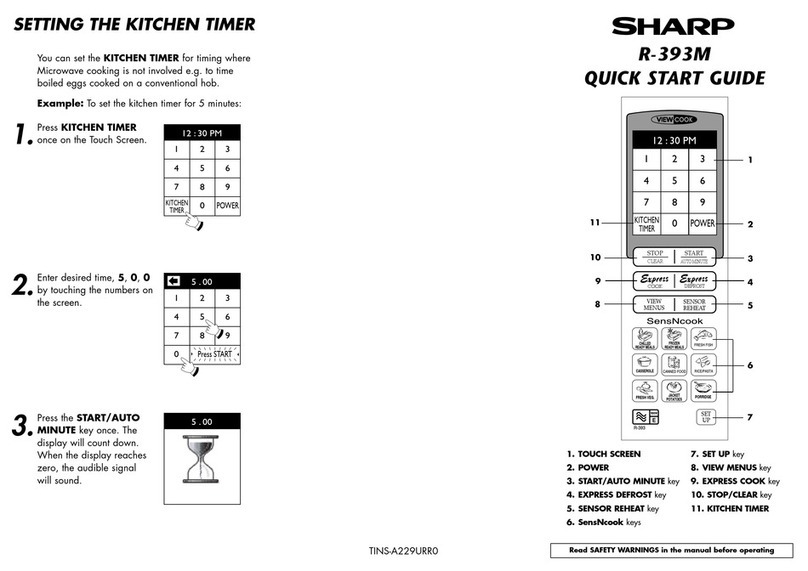

SENSOR TEST (QUICK TEST)

1. With 2 fingers touch and hold the following pads at

the same time:

Auto Defrost and Popcorn

2. Observe diagnostic number in display (Numbers

approximate).

● 15-185 (Normal-verify with “detection test” )

● 213 or Higher (Sensor failed to open, sensor un-

plugged, wiring or smart board).

● Less than 6 (shorted sensor or smart board).

NOTE: Only heater terminals (Black and Red leads)

can be checked with an ohmmeter (30Ω).

CAUTION: DO NOT ATTEMPT TO CHECK SENSOR

TERMINALS (White and Orange leads).

♣ CAN DAMAGE SENSOR.

TO TEST BLOWER WINDINGS: 1. Disconnect power and remove grill. 2. Open control panel and discharge

capacitor. 3. Continuity test across the two wires of the run capacitor should be approximately 120 ohms of resistance.

This test allows you to read across all three windings at the same time.

SMH1713B/XAA DE94-02411E

SMH1713W/XAA DE94-02411F

SMH1713S/XAA DE94-02411G

SE error. Touch switch not

available. Order control assy.