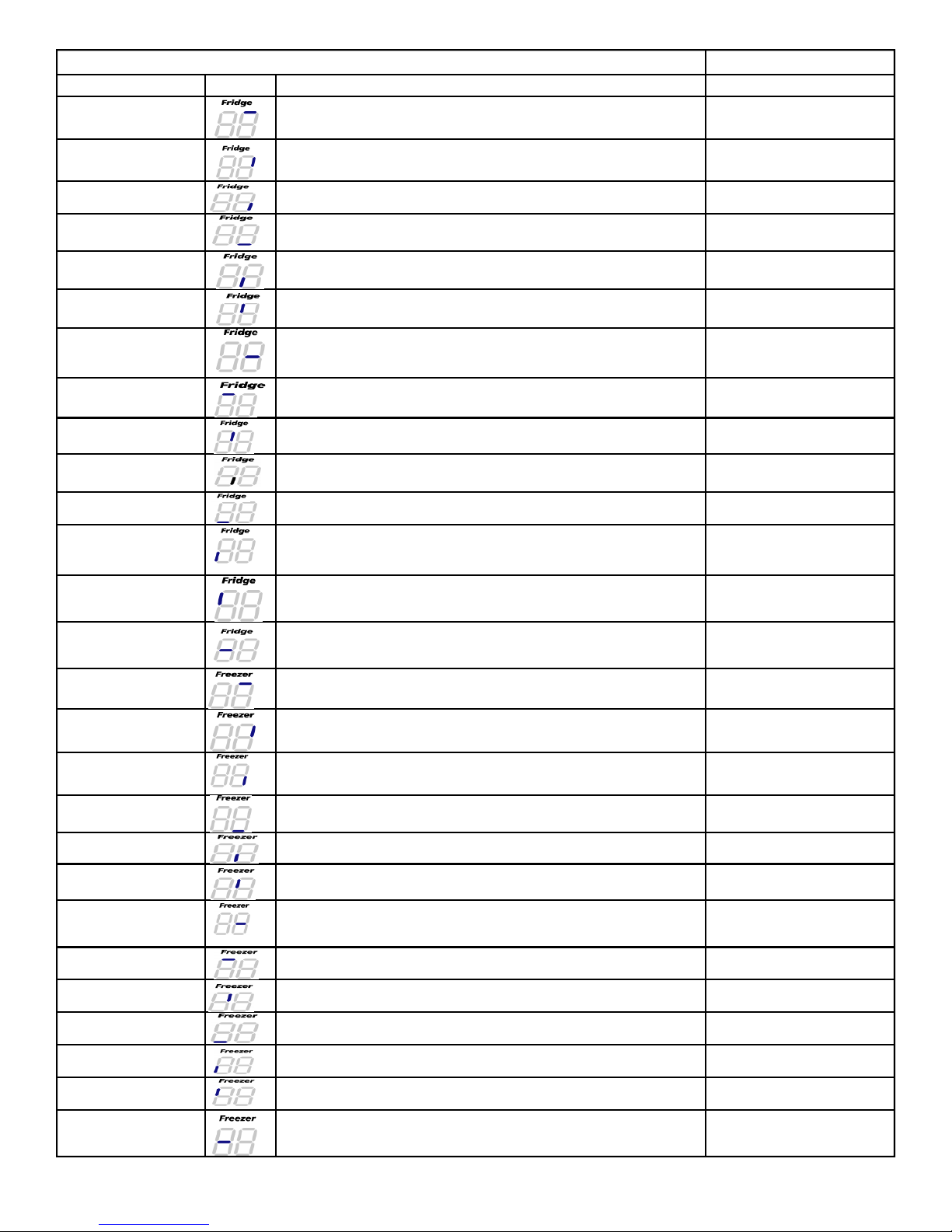

Error Items LED TROUBLE TESTING

I/M-SENSOR (R on Twin

I/M units)

Ice Maker Sensor Error- open or short-circuit, connector failure. Cause is

also a tempe rature reading > 122°or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

R-SENSOR Refrigerator Room Se nsor Error- open or short-circuit, connector fail ure.

Cause is also a temperature reading > 122 °or < -58 ° F.

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

DE FRO ST SE NSOR OF

R ROOM

Ref. Defrost Sensor Error- open or short-circuit, connector failure. Cause is

also a tempe rature readin

> 122 °or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

R-FAN ERROR This erro r indicates the Refrige rator Evap Fan is no t spinning at the correct

RPM or the fan feedback lin e is open.

Fan voltage at MAIN PCB shall

be between 7V~12 V

I/M FUNCTION

ERROR(R on Twin I/M)

This erro r indicates the Ice tray has not returned to level after an ice

harvest. The error is displayed after three failed attempts. Repl ace I/M

COOL SELECT ZONE

SENSOR

Cool Select Zone Sensor Error- open or short-circui t, connector failu re.

Cause is also a temperature reading > 122 °or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

R-DEFROSTING

ERROR

Refrigerator Room de frost heater- open or short-circui t, conne ctor failure,

or defective temperature fuse/bi-metal. Defrost on over 80 minutes

Disconnect defro st connector

from PCB, check re sistan ce

PANTRY-DAMPER-

HE ATER ERROR

Sensor system in Pantry Room err ors Disconnect heater connector

from PCB, check re sistan ce

CR-SENSOR 4-Door CR Ro om S ensor E rror - This can b e an open or short-circui t, contact

failur e. Cau se i s also a temperature re adin g > 122°or < -58 ° F.

The voltage of MAIN PCB

Sensor be tween 4 .5V~1.0V

DEFROST SENSOR CR

ROOM 4-Door

CR Room De frost Sensor Err or- open or shor t-circuit, conne ctor failure.

Cause is also a temperature reading > 122 °or < -58 ° F.

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

DE FRO ST SE NSOR OF

CF ROOM 4-Door

CF Room De frost Sensor Err or- open or shor t-circu it, connector failu re.

Cause is also a temperature readin

> 122°or < -58 ° F.

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

CR-DEFROSTING

ERROR 4-Door

CR Compartment Defrosting heater- open or short-circuit, conne ctor

failure, or defective temperature fuse/bi-metal. Defrost on for over 80

minutes

Disconnect heater connector

from PCB, check re sistan ce

CF-DEFROSTING

ERROR 4-Door

CF Compartment defro sting heater- open or short-circuit, connector failur e,

or defective temperature fuse/bi-metal. Defrost on for over 80 minutes

Disconnect heater connector

from PCB, check re sistan ce

WATER TANK HEATER

ERROR Err or is d isplayed when the water re servoir tank hea ter i s open or shorted

Disconnect heater connector

from PCB, check re sistan ce

EXT-SENSOR Ambient Temp. Sensor Error- open or sh ort-circuit, connector failure.

Cause is also a temperature reading > 122 °or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

F-SENSOR Free zer Compartment Se nsor Err or- op en or shor t-cir cuit, connector

failur e. Cau se i s also a temperature re adin g > 122°or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

F-DEF-SENSOR Freezer Room Defrost Sensor Error- op en or shor t- cir cuit, connector

failur e. Cau se i s also a tempe rature re ading > 12 2°or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

F-FAN ERROR This erro r indicates the Freezer Evap. Fan is no t spin ning at the correct

RPM or the fan feedback lin e is open.

Fan voltage at MAIN PCB shall

be between 7V~12 V

C-FAN ERROR This erro r indicates the Condenser Fan is not spinni ng at the correct RPM

or the fan feedback li ne is open.

Fan voltage at MAIN PCB shall

be between 7V~12 V

CF-SENSOR 4-Door CF Room Sensor Error - open or sh ort-circuit, connector failure. Cause is

also a tempe rature reading > 122°or < -58 ° F

The voltage at MAIN PCB

Sensor be tween 4 .5V~1.0V

F-DEFROSTING

ERROR

Free zer defrosting heater- op en or shor t-circuit, connector failu re, or

defective temperature fuse/bi-metal . Defrost on for over 80 minutes

Disconnect defro st connector

from PCB, check re sistan ce

CF-FAN ERROR

4-Door

This erro r indicates the CF Comp artment Evap. Fan is not sp innin g at the

correct RPM or the fan feedback lin e is open.

Fan voltage at MAIN PCB shall

be between 7V~12 V

CR-FAN ERROR

4-Door

This erro r indicates the CR Compartment Evap. Fan is not spinnin g at the

correct RPM or the fan feedback lin e is open.

Fan voltage at MAIN PCB shall

be between 7V~12 V

ICE PIPE HE ATER

ERROR Err or is d isplayed when the ice maker fill pi pe heater i s open or shor ted. Repl ace Fill Tube Ass'y

Uart ERROR

COMMUNICATION

This erro r is not applicabl e, if the erro r is detected during d iagnostic testing

ple ase i

nore it. No Repair Necessary

L?M ERROR

COMMUNICATION Communication error within the Main PCB Repl ace main PCB

P?M ERROR

COMMUNICATION Communication between the Main PCB an d Keypad Check wiring in door & cabinet,

Panel PCB, Main PCB

Samsung 'Refriger ator ' Diagnostic Code Quick Guide