-3-

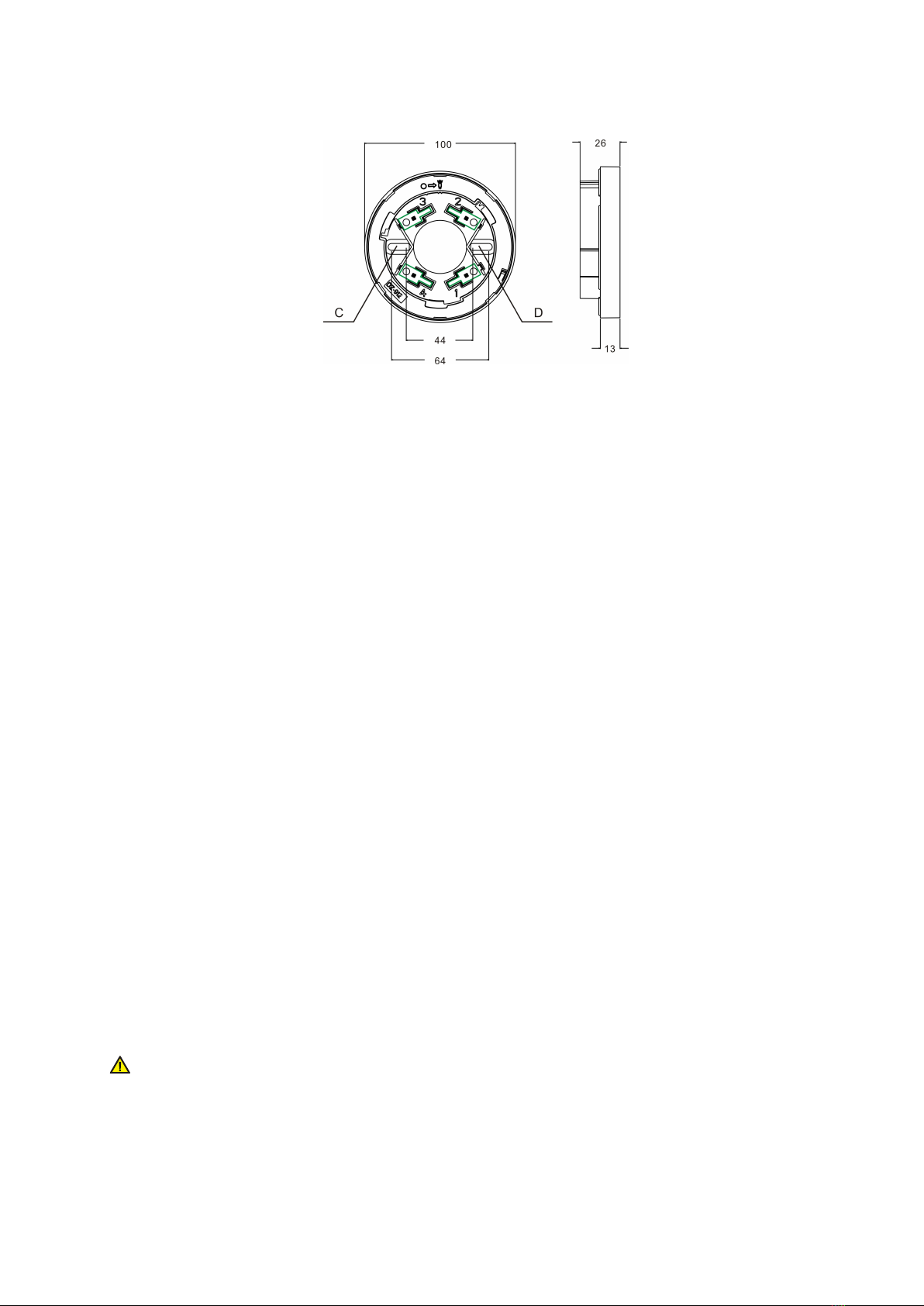

dimensions, the mounting hole diameter and the mounting hole spacing of the base are DZ-912, Ф100mm×26.4mm

(diameter×thickness), Ф4.5mm and 44.5mm~64.3mm respectively.

Fig.5

Wiring requirement:

It is proper to use RVS twisted pairs with a section area of equal to or larger than 1.0mm2for the signal buses L1 and L2.

7. Specific installation and debugging methods:

Make sure the type of the detector matches the type of the host machine of the fire alarm control panel;

Use two M4 screws to fix the matched mounting base on the designated position via the mounting holes C and D

shown in Fig.6, as instructed in the construction drawing and make sure the matched mounting base has been firmly

installed.

Use a coder to make the detector coded according to the detector address on the construction drawing.

Disconnect the power supply of the fire alarm control panel and connect the detector correctly according to the

The lower edge of the detector base raised position aligned with the groove position, and then the detector into the

base, the detector clockwise until it locks into place the detector.

After all the products are installed and checked, connect the power supply of the fire alarm control panel and conduct

When automatic login is success, the red indicator of the detector will blink once about every 12 seconds, which

suggests that the detector has begun to operate normally.

Finally conduct an alarm test for the detector through some special tools. After the detector gives a fire alarm, the

indicator will remain lit and the fire alarm control panel will simultaneously give corresponding alarm prompt

information. After the alarm test, reset the fire alarm control panel and restore to the monitoring status.

A detector can not share an address with other equipment in a single bus circuit, or else an address conflict may occur.

Never dismount the protective cover delivered with the detector too early after the field installation and before the use

of the detector, or else the detector may be contaminated.

The protection area and quantity of the detectors should comply with relevant provisions and regulations of the local

Warning: Before conducting maintenance for detectors, inform the related management department that the

monitoring will be stopped temporarily when the system maintenance. Meanwhile, disable the logic control function of

the area or system to be maintained to avoid unnecessary alarm linkage. After the test, inform the management

department to restore the normal functions of the system.

For a detector, at least semi-annual tests should be done according to related provisions and regulations

of the local codes; for a detector that has been installed and used, it is recommended to have it cleaned and

maintained once every two years.

Operating environment has a great influence on the performance of the detector. If the detector is installed

and used in a place where its normal use is easily affected by dust, high wind speed and other factors, its

maintenance period should be shortened.